Protective guard for scraper loader

A technology for raking gangue machine and guardrail, which is applied to the field of gangue raking machine guardrail, can solve the problems of force-removing the fixed anchor rod, time-consuming, affecting safety production, etc., so as to increase the safety factor, facilitate popularization and implementation, and have strong damage resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

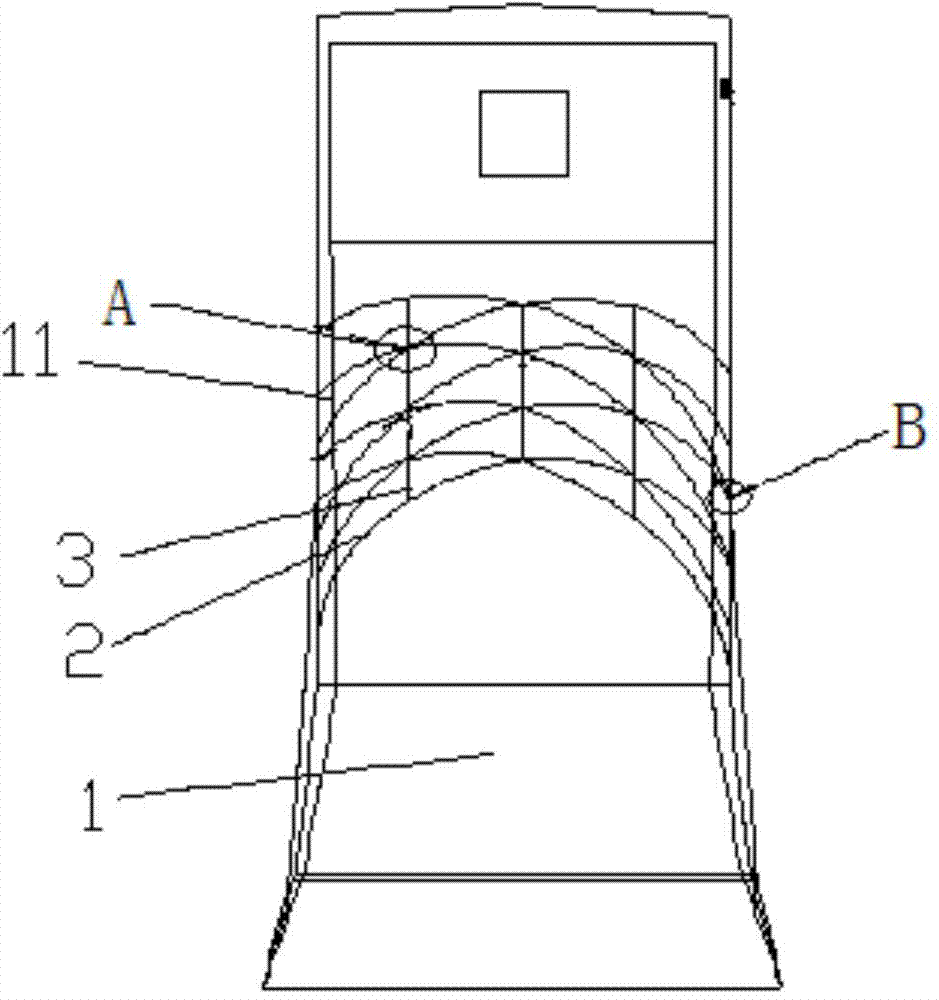

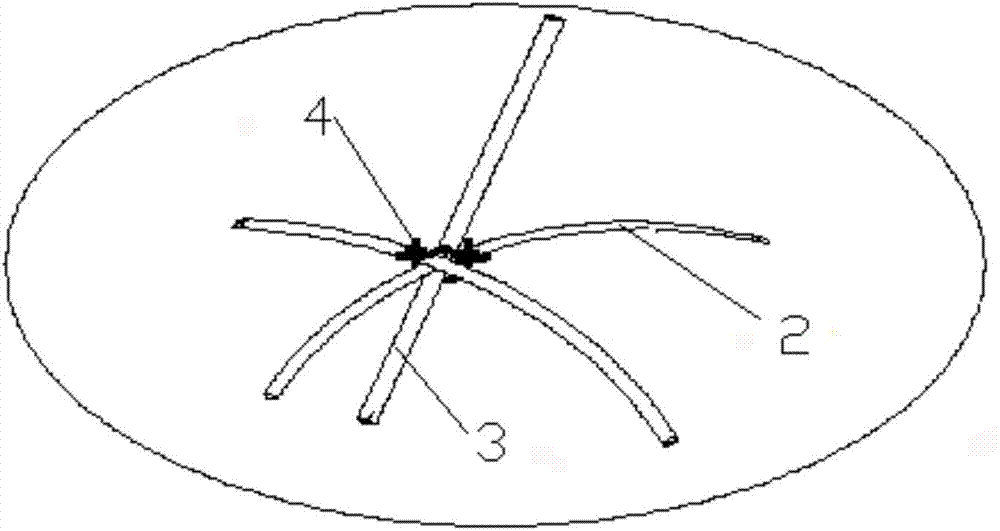

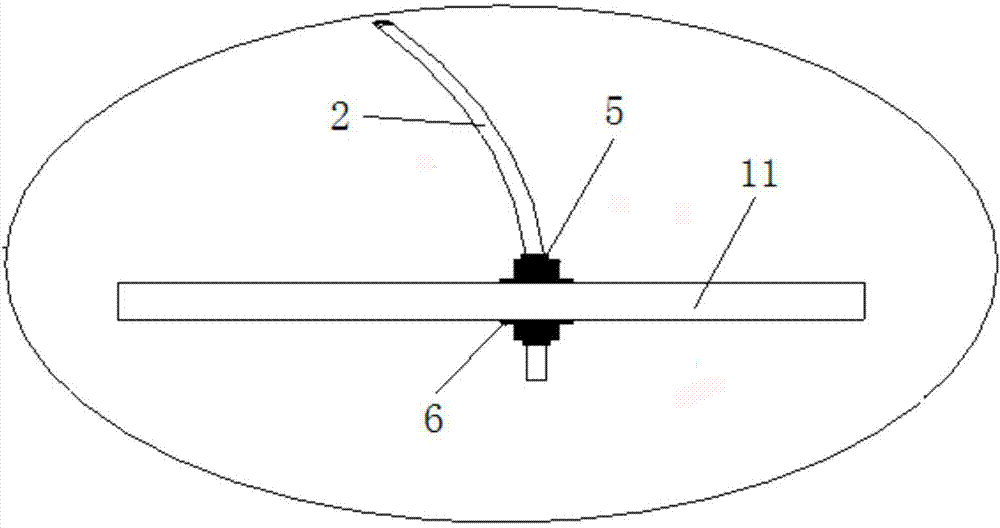

[0014] like Figure 1 to Figure 3 As shown, a rake machine guardrail of the present invention includes a rake machine body 1, and is characterized in that four equidistant holes are respectively arranged on the sides 11 of the rake machine 1. The steel strand rope 2 is cross-connected in the hole described above, and the steel strand rope 2 is fixed on the groove side 11 through the lock 5, and a gasket 6 is arranged between the lock 5 and the groove side 11, and the steel strand rope 2 Each row of intersections is provided with a disc unit 3, and the intersection point of the disc unit 3 and the steel strand 2 is fixed by a U-shaped clip 4.

[0015] Further, the diameter of the disc unit 3 is 6.5 mm.

[0016] Further, the length of the steel strand 2 is 4m.

[0017] Implementation method of the present invention: Drill 8 holes with a diameter of 20 mm at an equidistant distance of 300 mm on the side panels 11 on both sides of the rake machine 1 trolley chute; cross the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com