Artificial intervertebral disc prosthesis based on metal rubber

A technology of metal rubber and intervertebral discs, applied in the direction of spinal implants, etc., can solve the problem that the support stiffness and damping energy consumption cannot be taken into account at the same time, and achieve the effects of superior performance, strong resistance to damage, and low wear of the nucleus pulposus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

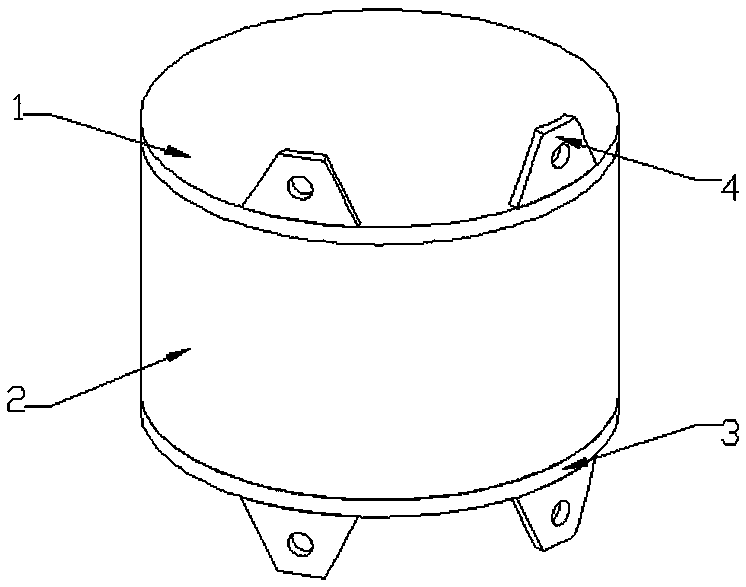

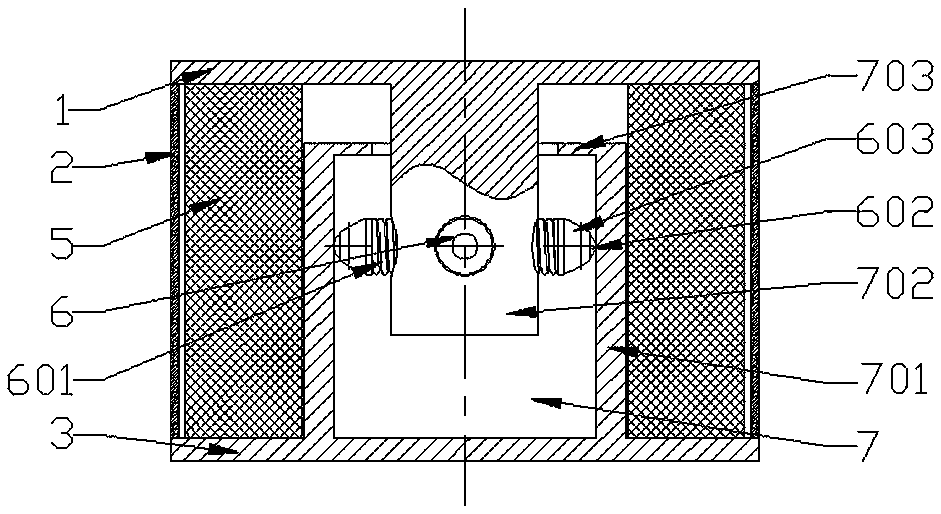

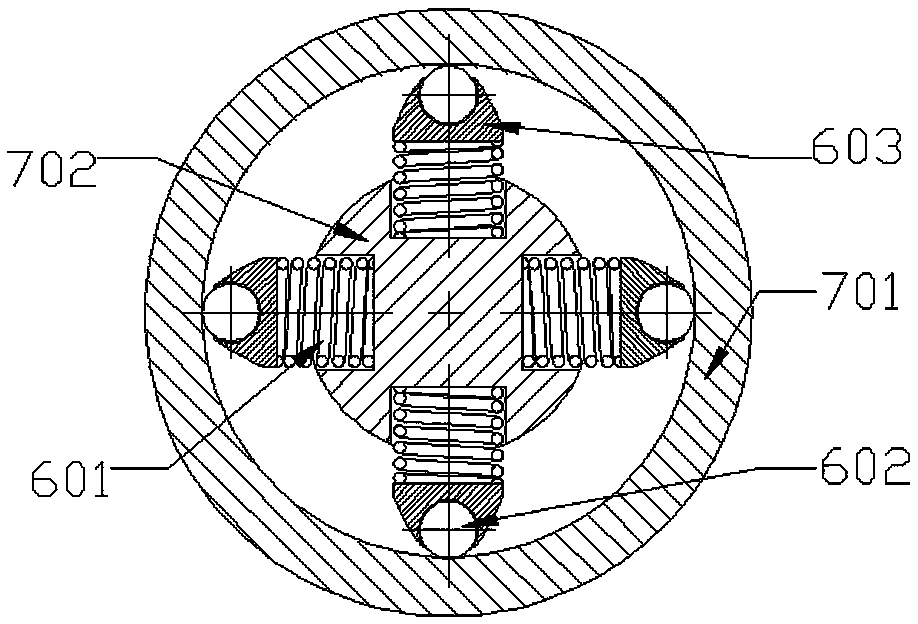

[0016] Such as Figure 1~3 As shown, a metal rubber-based artificial intervertebral disc prosthesis includes an upper endplate 1, a lower endplate 31, and an outer sheath 2 surrounded by a circle between the upper endplate 1 and the lower endplate 3; the outer sheath 2 The inner side is provided with a hollow metal rubber cylinder 5 that is pressed together by the upper endplate and the lower endplate. The metal rubber cylinder is formed by braiding and punching stainless steel wires; A sleeve 701 in the hole in the body, the lower side of the upper end plate 1 is provided with a shaft 702 extending downward into the sleeve 701, the sleeve and the shaft form a sleeve assembly 7, and the circumference of the shaft 702 is evenly distributed There are multiple elastic ball moving devices 6 against the inner wall of the sleeve to reduce the frictional force between the sleeve and the shaft; the metal rubber cylinder 5 has a certain amount of preload in the axial direction to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com