Measuring method for viscosity of alkali cellulose

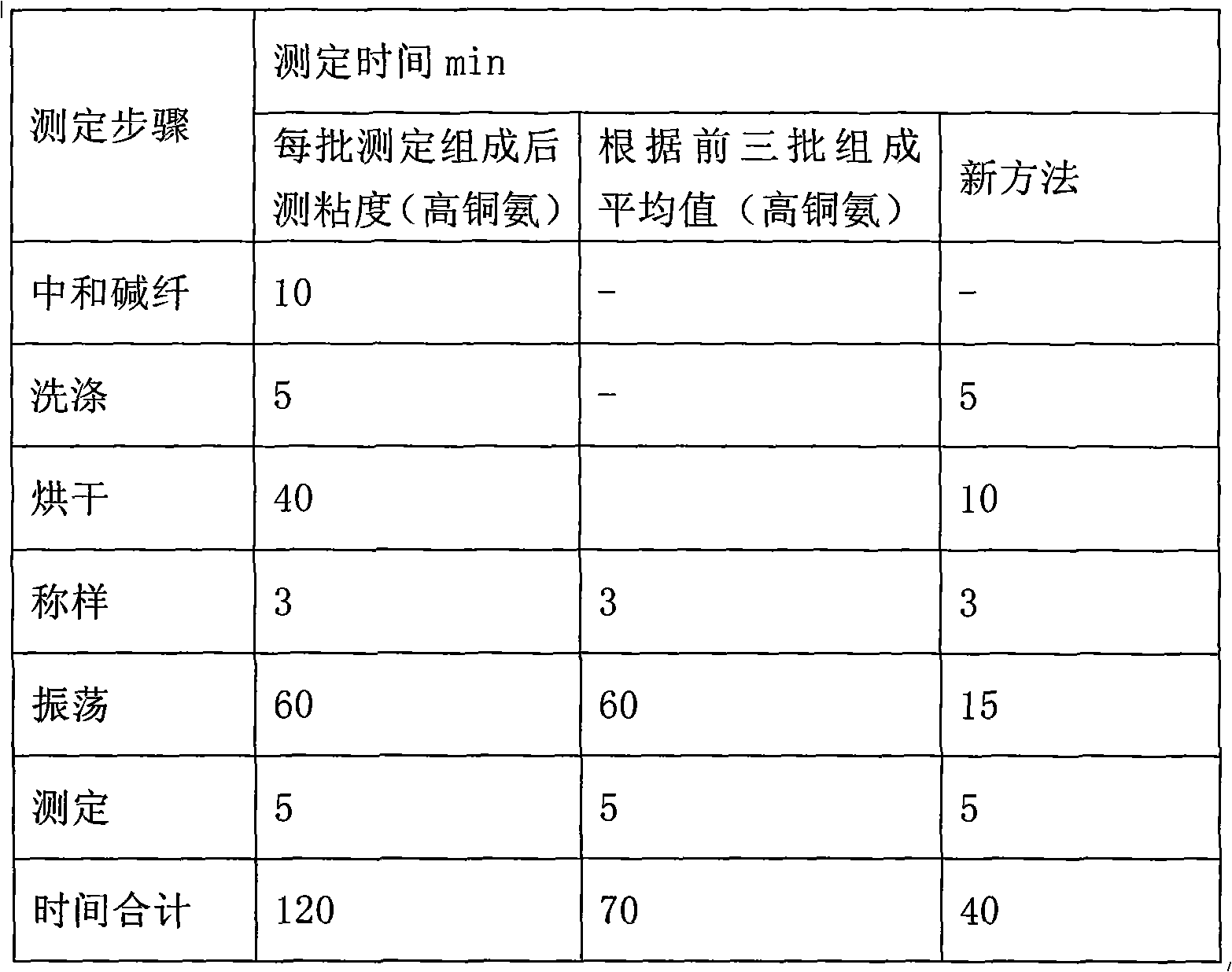

A viscosity measurement and alkali fiber technology, which is applied in the field of alkali fiber viscosity measurement, can solve the problems of inaccurate alkali fiber viscosity measurement, etc., and achieve the effects of shortening the oscillation time, good dispersion state, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The alkali fiber viscosity measurement method is to soak the alkali fiber sample in distilled water, disperse it with a beater with a power of 210W, and then use a vacuum pump with a model of 2XZ-1 to carry out suction filtration and washing on a G2 sand core crucible until it is washed to use There is no red color in the phenolphthalein test; the washed sample is suction-filtered into a pancake in a Buchner funnel with a clean filter cloth of 8 cm in diameter, and then baked in a WS-70-1 infrared oven at a temperature of 250 ° C for 8 minutes, and then used The AB204-N electronic balance quickly weighed 0.3535g within 50 seconds and placed it in a small brown bottle containing 35ml cuproammonia solution (13g / L for copper and 150g / L for ammonia). The copper strips were plugged tightly with rubber stoppers, and then placed in a constant temperature room with a frequency of 200-240 beats per minute on a Kangen oscillator for 10 minutes until the sample was completely disso...

Embodiment 2

[0025] The alkali fiber viscosity measurement method is to soak the alkali fiber sample in distilled water, disperse it with a beater with a power of 210W, and then filter and wash it with a 2XZ-1 vacuum pump on a G2 sand core crucible until it is washed with 1% phenolphthalein. There is no redness in the test; the washed sample is suction-filtered into a pancake in a Buchner funnel with a clean filter cloth and a diameter of 10cm, and then baked in a WS-70-1 infrared oven at a temperature of 220°C for 9 minutes, and then washed with AB204 -N electronic balance quickly weighed 0.3535g within 60 seconds and placed it in a small brown bottle containing 35ml cuproammonia solution (13.2g / L for copper and 152g / L for ammonia). The copper strips were plugged tightly with rubber stoppers, and then placed in a constant temperature room with a frequency of 200-240 times / min on a Kangen oscillator for 15 minutes until the sample was completely dissolved. The solution is injected into a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com