Transformer oil tank structure

A technology for transformer oil tank and box edge, which is applied in the direction of transformer/inductor cooling, etc., can solve the problems of increased product repair, hidden safety hazards, complicated procedures, etc., and achieves the effects of good integrity, improved reliability, and large welding surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

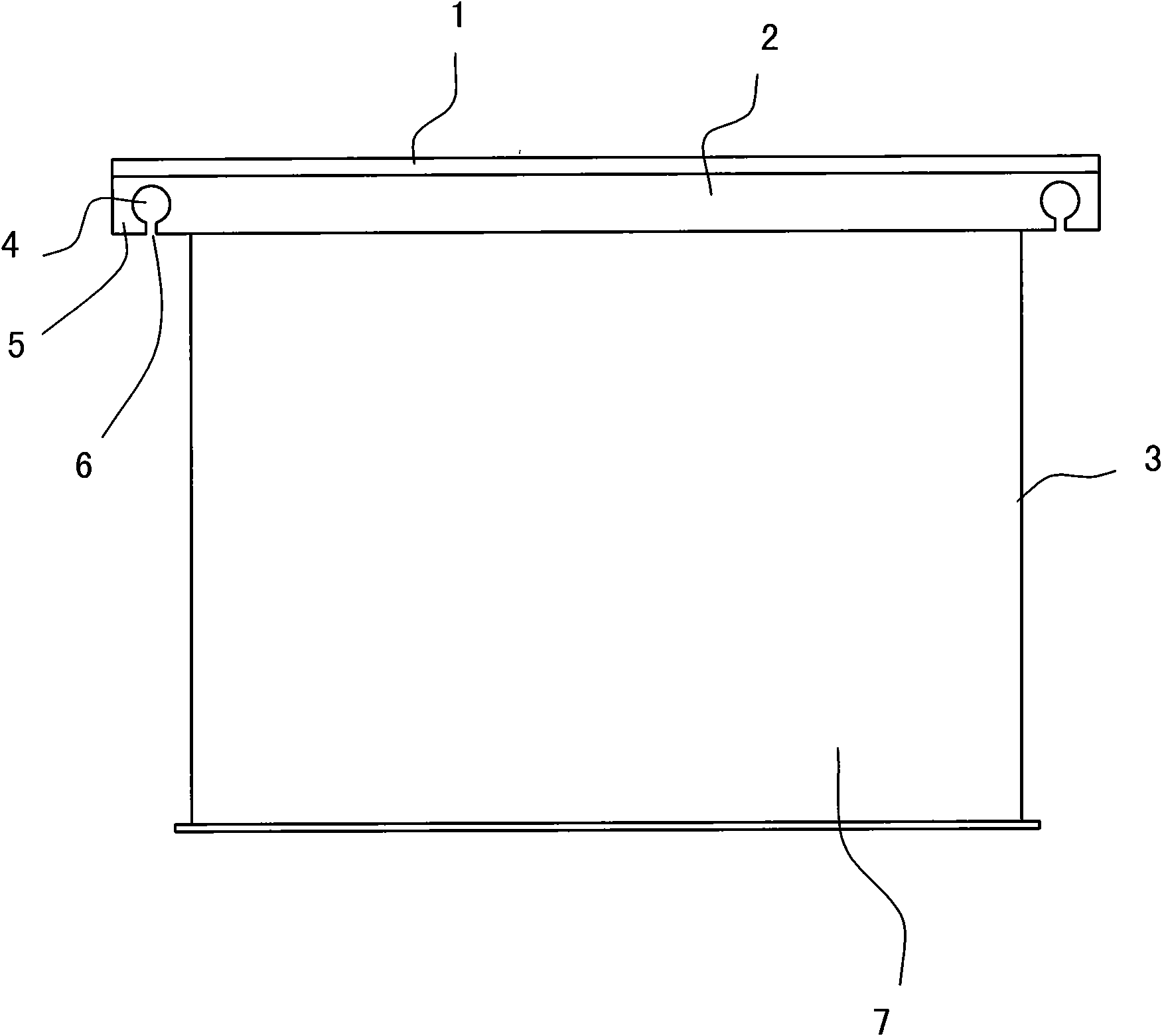

[0012] see figure 1 . The top box cover 1 is fixedly connected to the horizontal edge of the box edge 2 formed by multiple fasteners and angle steel (that is, the "7"-shaped box edge 2 with a right-angled longitudinal section), and the connecting surface between the box cover 1 and the box edge 2 There is a sealing piece on the top to ensure the sealing. The opening of the box along the vertical limit of 2 and casing 3, the thickness is solidly welded into one. There are four along the box edge 2, two oppositely installed boxes along the two ends of the box edge 2, figure 1 Shown are the two box edges 2 in the width direction, grow out of the width to the box wall 7 respectively, and offer a through hole 4 respectively on the vertical edge (i.e. the hanging plate 5) of the box edge growing out of the box wall 7, each corner There is a through hole 4 on it, which is used as the ring hole.

[0013] The concrete numerical value that above-mentioned grows width to box body wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com