Double-sided flexible printed circuit board with ACP conductive adhesive being printed thereon

A flexible printing and circuit board technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit components, etc., can solve problems such as difficult operation, broken AG wire, uneven glue coating, etc., to eliminate potential safety hazards and improve Good production efficiency and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

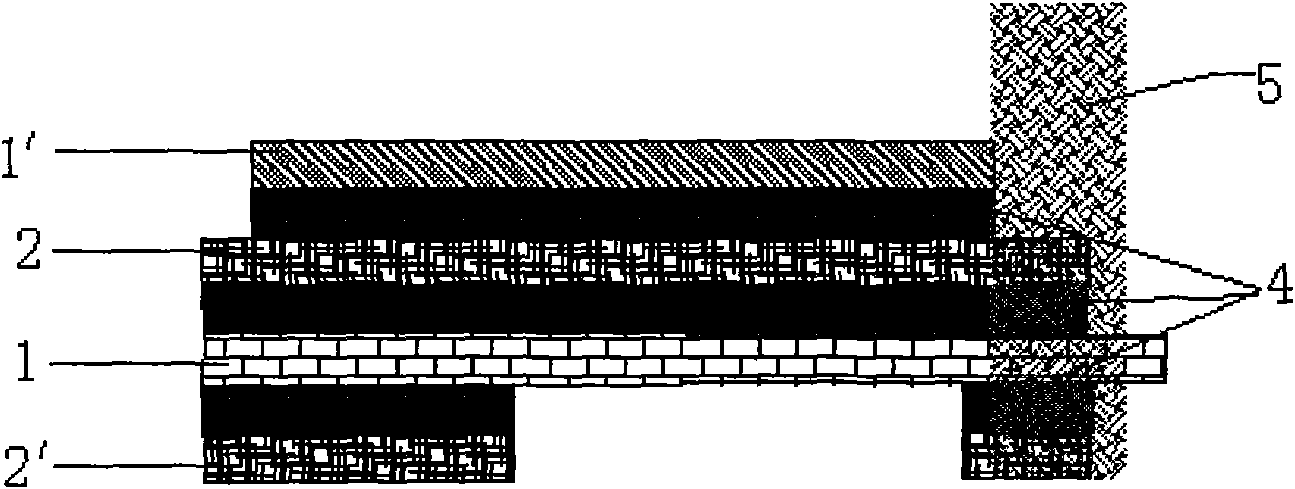

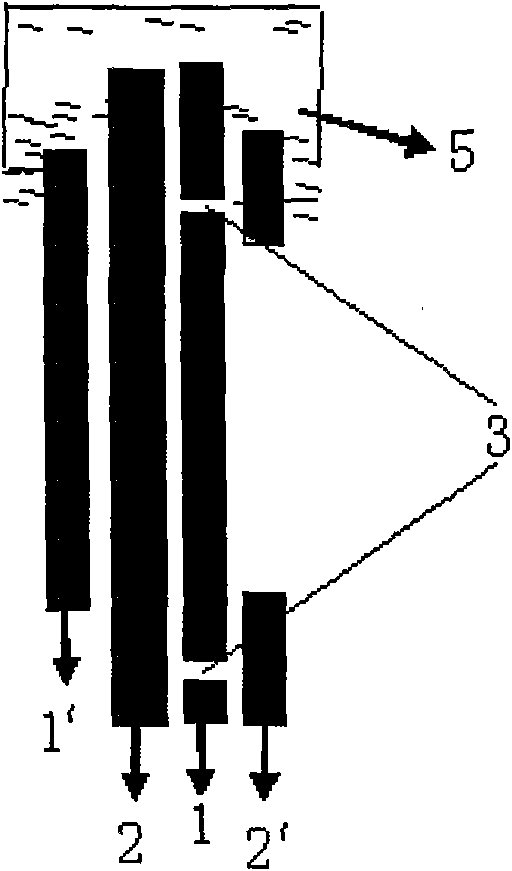

[0021] figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention; figure 2 It is a structural side view of an embodiment of the present invention.

[0022] Such as figure 1 with figure 2 As shown, a double-sided flexible printed circuit board printed with ACP conductive glue includes a substrate and a circuit distributed thereon. The substrate is a double-sided board, which is composed of upper copper foil 2, AD glue 4, The layered structure composed of PI film 1, AD glue 4 and lower layer copper foil 2' has a circuit pattern formed on the upper layer copper foil 2 and the lower layer copper foil 2', and between the upper layer copper foil 2 and the lower layer copper foil 2' A guide hole 3 for communication between the upper and lower sides is provided, and the surface of the upper layer copper foil 2 of the substrate is covered with an insulating layer exposing solder joints, the insulating layer is a PI cover film 1', and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com