Method and equipment for detecting sealing deficiencies in drainage and vent systems for buildings

A ventilation system and drainage system technology, applied in the water supply pipeline system, fluid tightness test, and by detecting the appearance of fluid at the leakage point, etc., it can solve the problems of waste water pushing in, breaking fast water seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

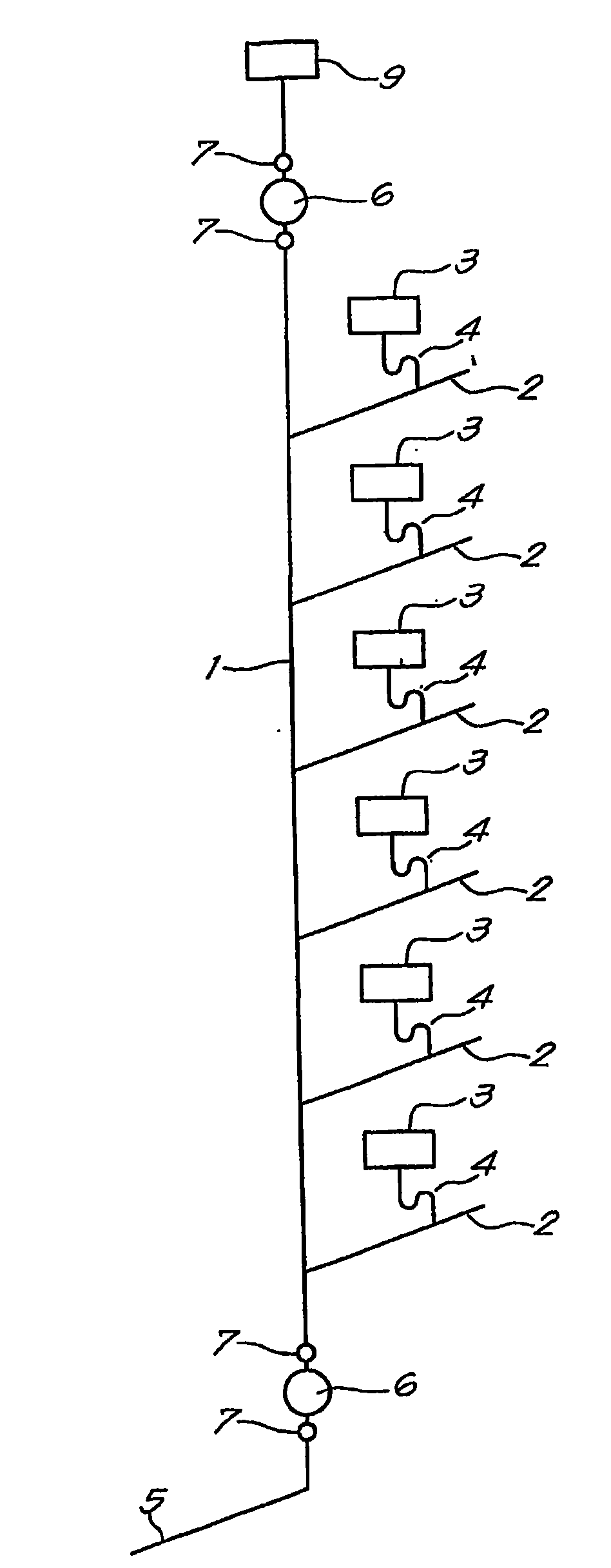

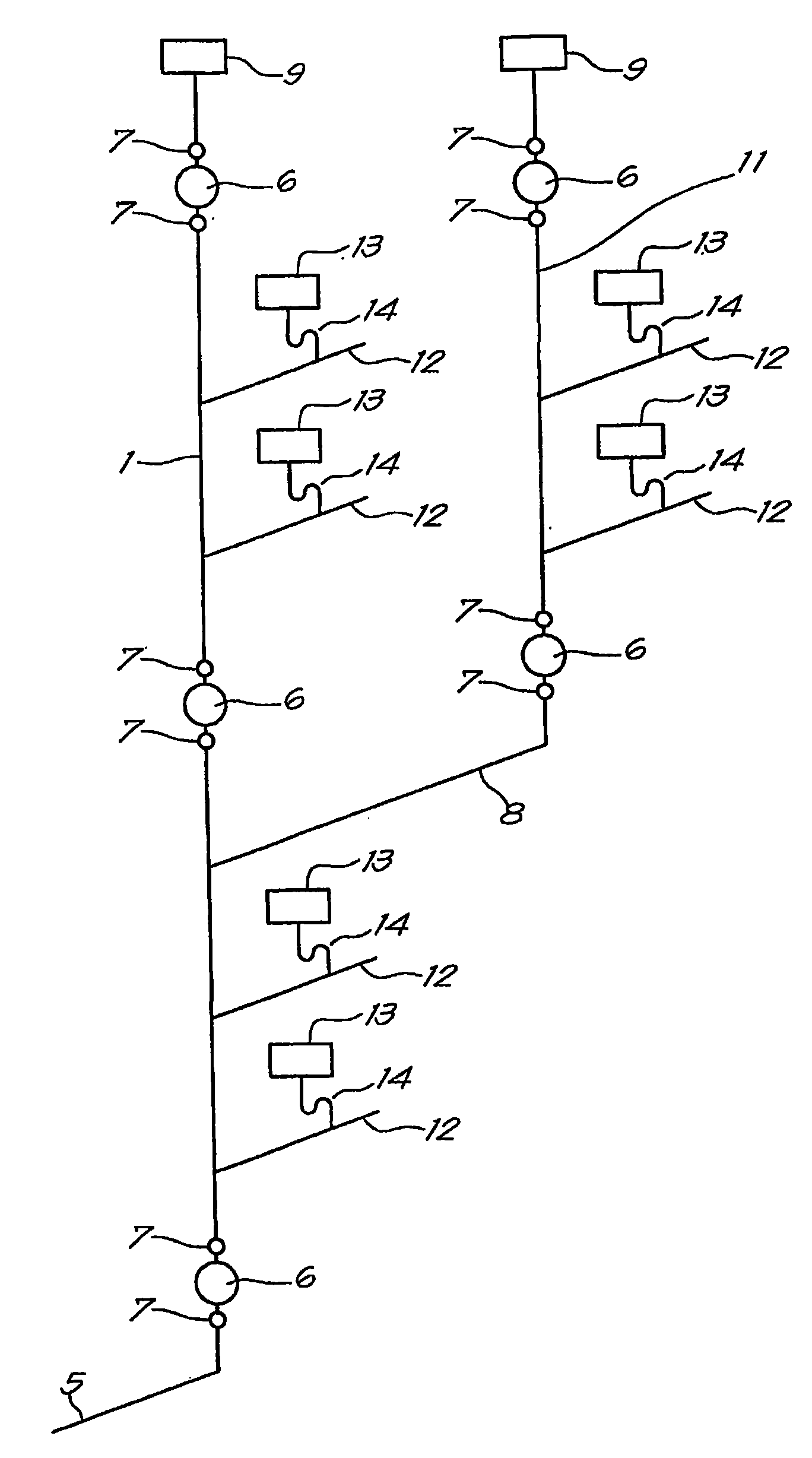

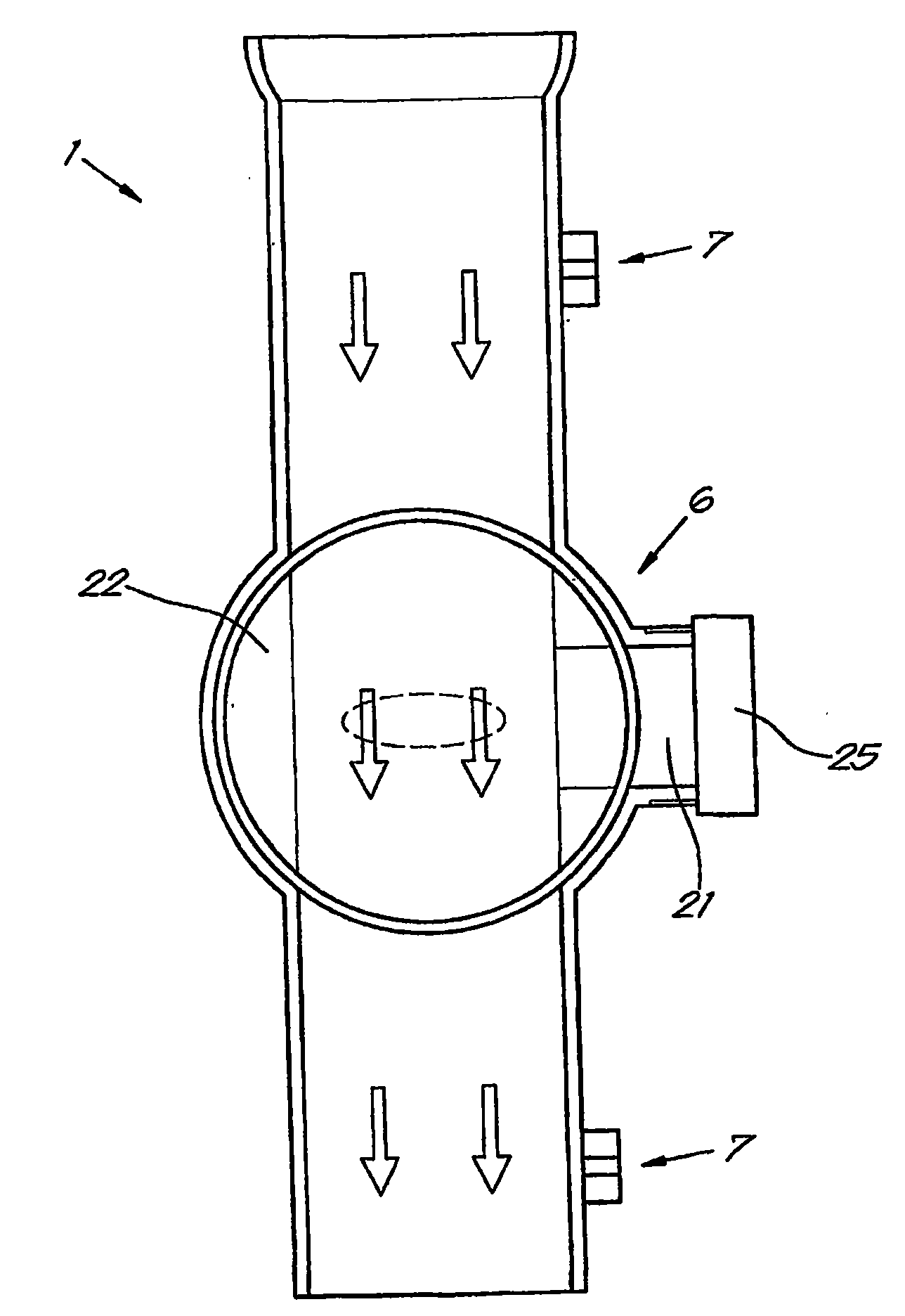

[0019] Such as figure 1 As shown, a drainage system of a multi-storey building is shown in a simplified manner, comprising a vertical riser discharge pipe 1, to which a series of drain pipes 2 from each floor are connected, and discharge sources from each floor 3 can leak into it. The discharge source may be any sanitary fixture such as a toilet, floor drain, sink, shower, bidet, and the like.

[0020] Between each discharge source 3 and the drain pipe 2, the pipeline generally includes a U-shaped water trap 4 (water trap) or the like.

[0021] Liquid and / or liquid / solid effluents from discharge sources 3 are conveyed through their respective dehydrators 4 to drains 2 and then through vertical standpipes 1 finally into drains 5 .

[0022] The complete system is vented to the surrounding atmosphere by means of an air admission valve 9, which is generally arranged at the uppermost end of the standpipe 1, but may also be contained in the housing of the water seal. As already e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com