Method and device for determining an operating characteristic of an injection system

A technology of injection system and operation characteristics, applied in the direction of fuel injection control, electrical control, combustion engine, etc., can solve problems such as difficulty in manufacturing tolerance injection quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

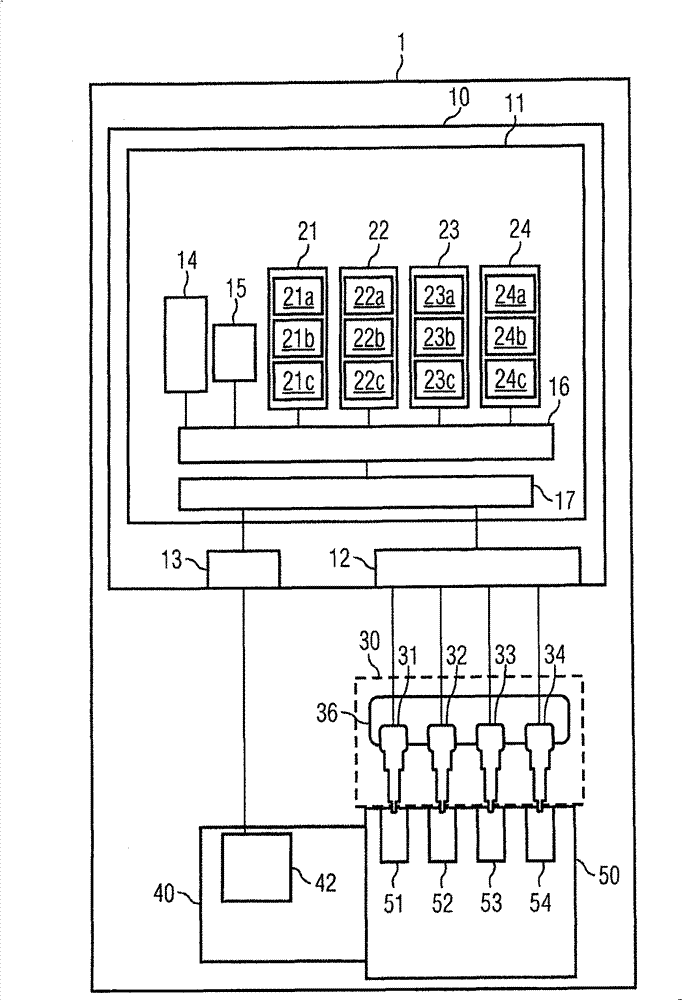

[0024] figure 1 An engine 1 is shown in one embodiment of the invention. The engine 1 includes an engine control unit ECU 10 , an injection system 30 , a supercharger 40 and an engine body 50 .

[0025] The injection system 30 is a common rail system. It comprises an accumulator 36 and four injectors 31 , 32 , 33 , 34 connected with the accumulator 36 .

[0026] The engine block 50 includes four cylinders 51 , 52 , 53 , 54 . Each cylinder 51 , 52 , 53 , 54 is assigned an injector 31 , 32 , 33 , 34 .

[0027] Connected to the engine block 50 is a supercharger 40 which may be driven by combustion gases flowing out of the cylinders 51, 52, 53, 54 and through which compressed air may be introduced into the cylinders 51, 52, 53, 54. in the combustion chamber. The supercharger 40 includes a supercharger measuring device 42 , which measures the rotational speed of a turbine of the supercharger 40 , not shown further here.

[0028] The ECU 10 includes an electronic circuit 11 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com