Threshing mechanism and reaping machine using same

The technology of a threshing device and a harvester is applied to a harvester that integrates threshing and collection, and integrates cutting and separation. , full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

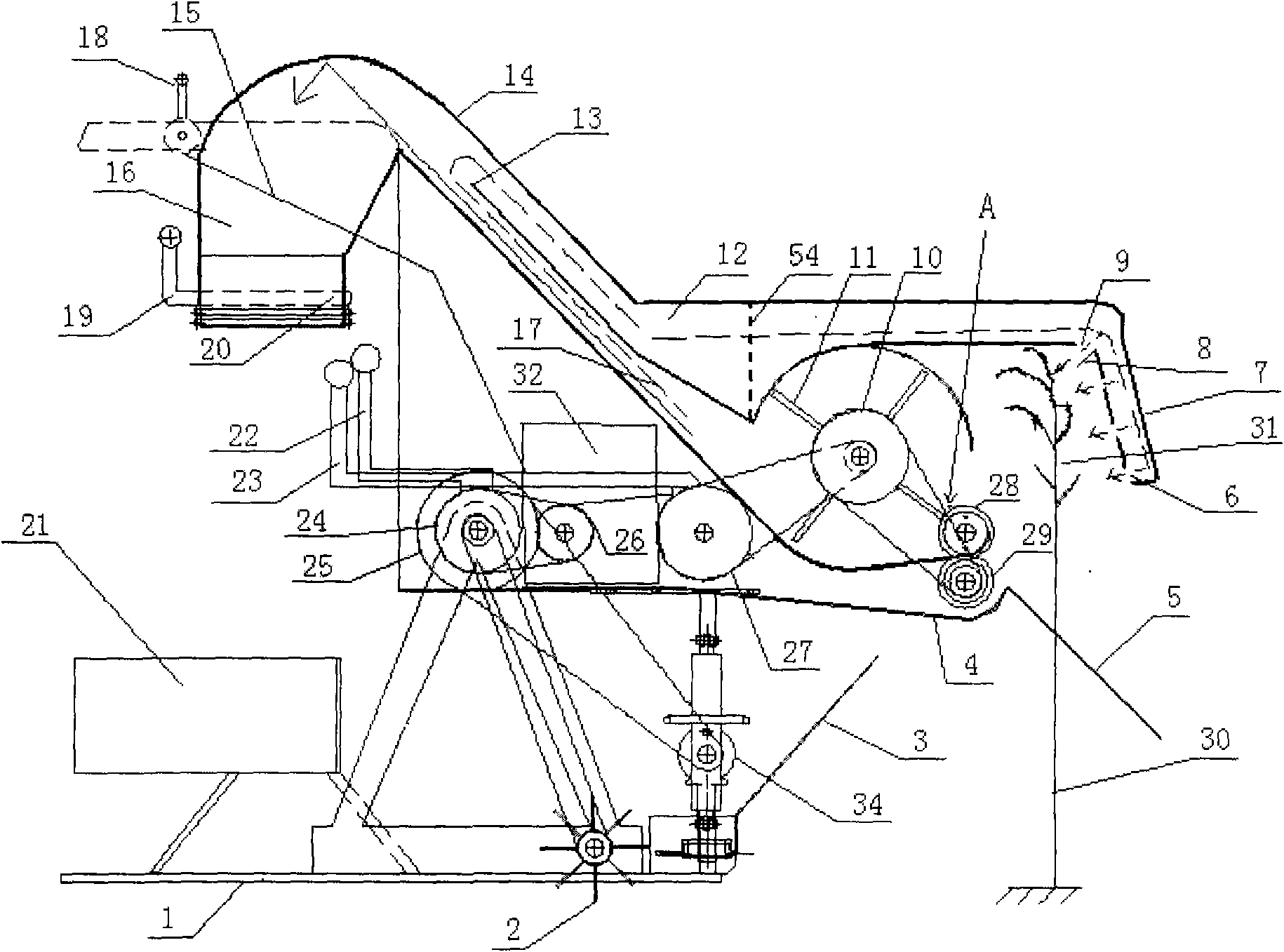

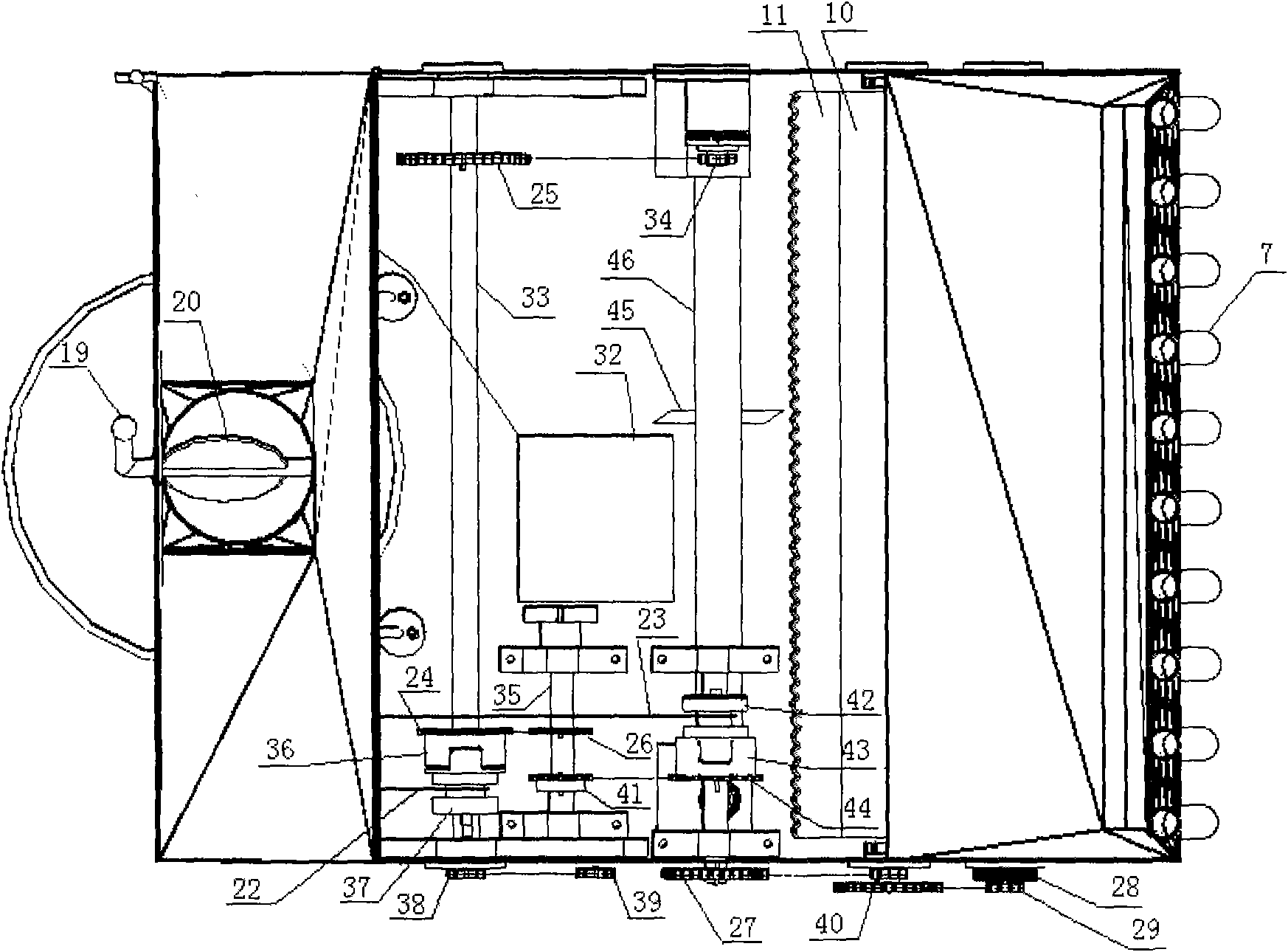

[0023] See Figure 1 to Figure 3 , the harvester includes a frame 1, and the frame 1 is equipped with a traveling device, a position regulating device, a power device, a cutting device, a transmission device, a collecting device and a threshing device, and the traveling device, the position regulating device, the cutting device and the threshing device pass through the transmission device It is connected with the power device, and the operation of each part is controlled by the power device.

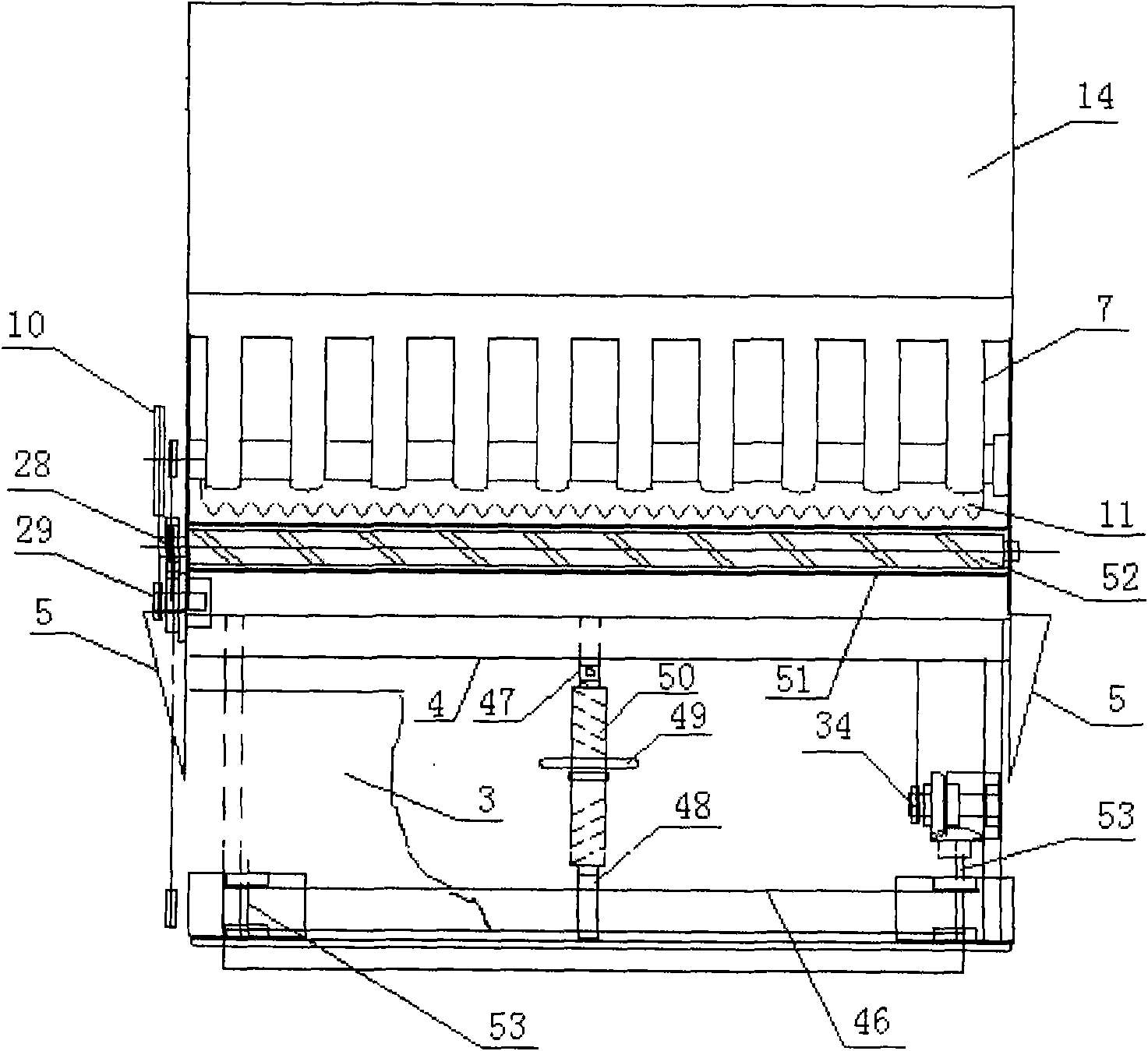

[0024] The threshing device includes an air duct 14, the upper part of the air duct 14 is connected to the aggregate chamber 16, and the air duct 14 is separated by an air return plate 13, and is divided into a downwind channel 17 and an upwind channel 12, and the inlet end of the downwind channel 17 is provided with a wind wheel 10 With the corresponding straw 52, the edge of the blade 11 of the wind wheel 10 is serrated, and the surface of the straw 52 is right-handed. The rods 52 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com