Rope belt symmetrizing tension device

A tensioning device and balanced technology, applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., to achieve the effect of balanced tension and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

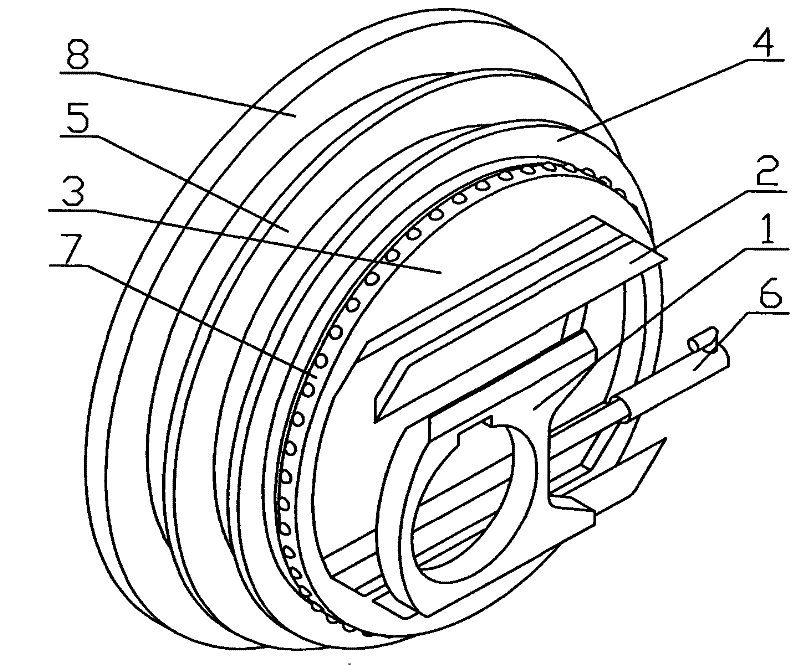

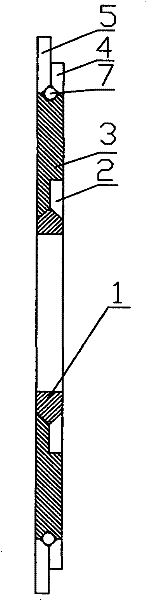

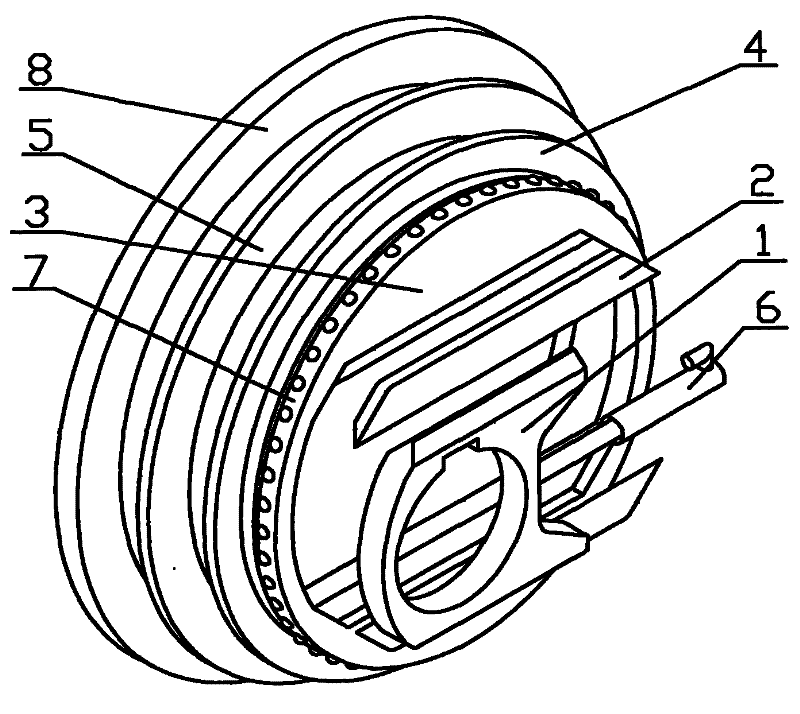

[0011] Such as figure 1 with figure 2 As shown, the rope belt balanced tensioning device of the present invention includes a support seat 1, a guide rail pressing plate 2, a bearing inner ring 3, a bearing right outer ring 4, a bearing left outer ring 5, a hydraulic cylinder 6, a bearing ball 7 and a tension wheel 8. The bearing inner ring 3 and the guide rail pressure plate 2 are buckled to form a V-shaped moving guide surface (see figure 2 ) And form a V-shaped movable rail pair with the rail surface on the support base 1. The bearing right outer ring 4 and the bearing left outer ring 5 are buckled together to form the outer ring of the bearing. The piston rod of the hydraulic cylinder 6 is mounted on the support base 1, and the cylinder barrel is mounted on the bearing inner ring 3. The tension wheel 8 is fixed on the right outer ring 4 of the bearing.

[0012] In use, the support base 1 is installed on the support shaft of the tension wheel of the multi-rope diamond bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com