Multi-grade comprehensive utilization technology of fluoride-contained waste acid in phosphating industry

An industrial and fluorosilicic acid technology, applied in the multi-stage comprehensive utilization of fluorine-containing waste acid in the phosphating industry, which can solve the problems of high treatment costs, environmental pollution resources, and lack of good technical solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

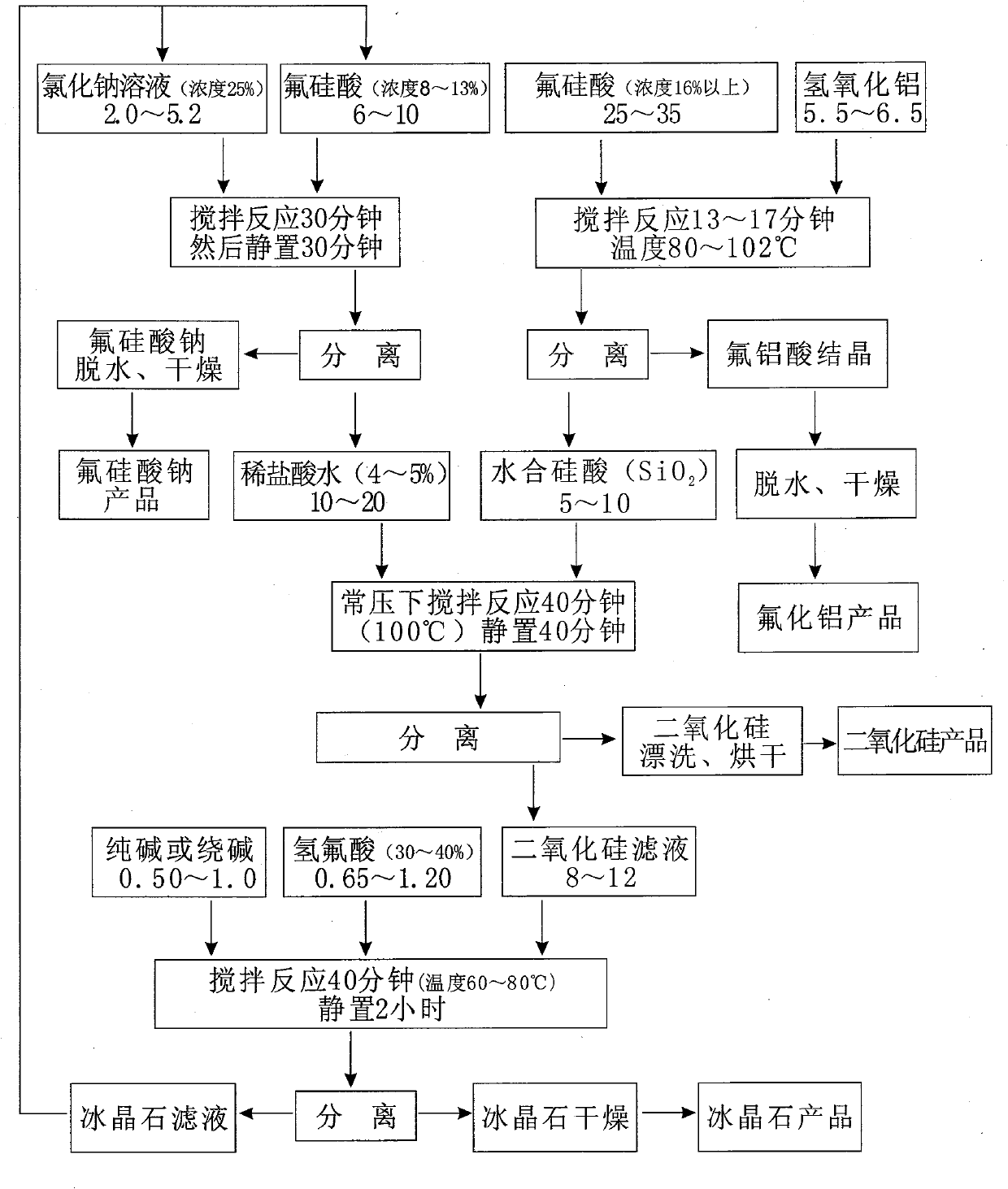

Method used

Image

Examples

Embodiment 1

[0041] ①. Preparation of sodium fluorosilicate and dilute hydrochloric acid water

[0042] Raw material ratio:

[0043] Fluorosilicate (H 2 SiF 6 , concentration 11%): 10L

[0044] Sodium chloride (NaCl, concentration 25%): 4L

[0045] The above-mentioned fluorosilicic acid (H 2 SiF 6 ) into a reaction barrel with a volume of 20L, add the above-mentioned sodium chloride solution to react with it for 30 minutes and then let it stand for 30 minutes, carry out suction filtration, and obtain sodium fluorosilicate product through dehydration and drying. In the one-step processing link, after testing, the concentration of hydrochloric acid in the filtrate is 4.85%.

[0046] ②. Preparation of aluminum fluoride and hydrated silicic acid (SiO 2 )

[0047] Raw material ratio:

[0048] Fluorosilicate (H 2 SiF 6 , concentration 17%): 30L

[0049] Aluminum hydroxide Al(OH) 3 : 6.3kg

[0050] Take 30L of fluosilicic acid with the above concentration and put it into a plastic-l...

Embodiment 2

[0070] 1. Modulate the concentration of fluosilicic acid with the cryolite filtrate obtained in 4 in Example 1 to prepare sodium fluosilicate and dilute hydrochloric acid water.

[0071] Raw material ratio:

[0072] Cryolite filtrate: 4.6L

[0073] Fluorosilicate (H 2 SiF 6 , concentration 17%): 6.8L

[0074] Sodium chloride (NaCl, concentration 25%): 5.5L

[0075] Take 4.6L of the filtrate after cryolite preparation in Item 4 of Example 1, add 6.8L of 17% fluosilicic acid, 5.5L of 25% sodium chloride solution, and stir the reaction in a reaction tank with a volume of 20L After 30 minutes, stop stirring, let stand for 30 minutes, and perform suction filtration to obtain sodium fluorosilicate product. Measured its Na 2 SiF 6 Content is 98.46%, and its filtrate is processed the same as embodiment 1 to produce aluminum fluoride by-product --- hydrated silicic acid (SiO 2 ) of the leaching solution, the steps of the latter stages are the same as in Example 1, and its react...

Embodiment 3

[0077] 1. Add sodium hydroxide (NaOH) to the silicon dioxide filtrate obtained in the same manner as 1, 2, and 3 in Example 1 to produce cryolite.

[0078] Raw material ratio:

[0079] Silica filtrate: 10L

[0080] Sodium hydroxide: 513g

[0081] Hydrofluoric acid (HF, concentration 40%): 850g

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com