Cereal flour composition containing low-temperature gelatinizing wheat-derived flour and food using the same

一种谷物粉、组合物的技术,应用在油炸食品、焙烤食品、食品制备等方向,能够解决直链淀粉增加、尚未实用化、不适合加工面包等问题,达到柔软口溶性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The production of staple bread

[0094] Make staple food bread with the batching (mass part) shown below.

[0095] Wheat Flour 100

[0096] Fermented food 0.1

[0097] Granulated sugar 5

[0098] salt 2

[0099] skimmed milk powder 2

[0100] shortening 5

[0101] Yeast 2

[0102] water 68

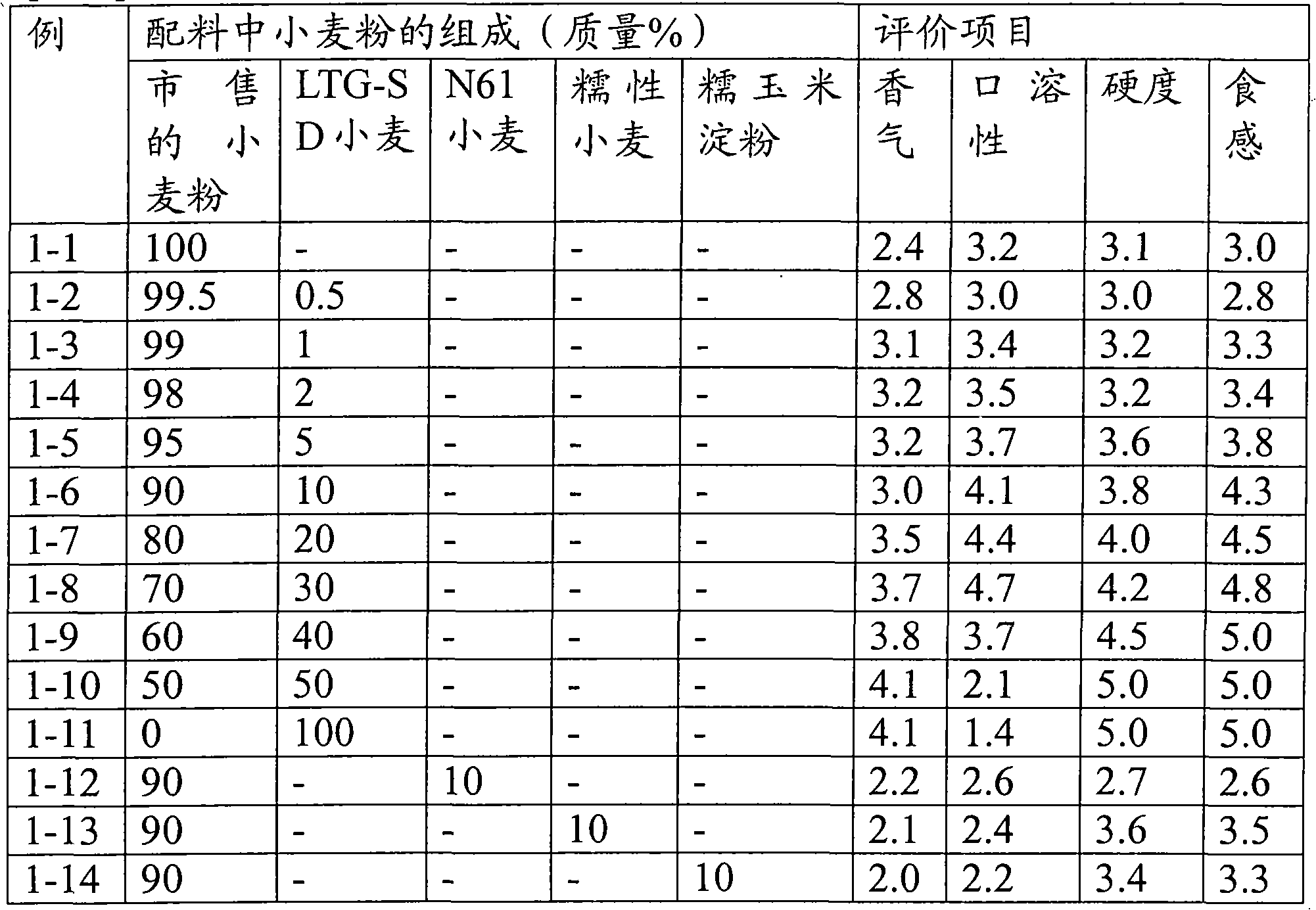

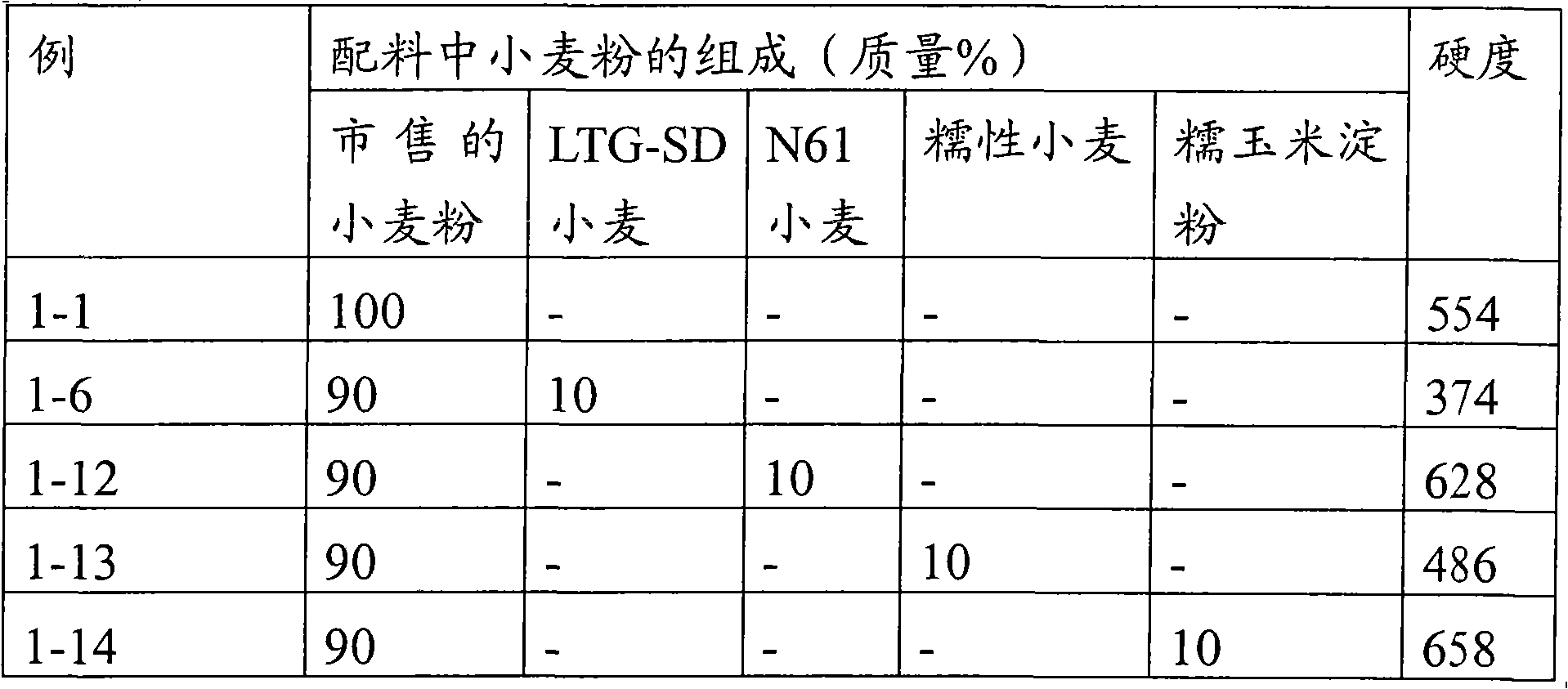

[0103] The wheat flour composition in the above-mentioned batching is to use commercially available wheat flour, the above-mentioned prepared wheat flour obtained by LTG-SD wheat, the wheat flour obtained by N61 wheat, the wheat flour obtained by waxy wheat and waxy cornstarch, according to the composition in Table 1 ( mass%) constituted.

[0104] In addition, in the test, the use of strong powder Eagle TM (manufactured by Nippon Milling Co., Ltd.) as commercially available wheat flour. In the ingredient list, mix ingredients other than shortening, and use a mixer (SK MIXER TYPESK21C) to stir for 2 minutes at low speed, 3 minutes at medium speed, and 1 minute at high speed...

Embodiment 2

[0137] Making of muffins

[0138] Make sponge cake with the batching (mass part) shown below.

[0139] wheat flour 100

[0140] Granulated sugar 125

[0141] whole egg 175

[0142] The wheat flour composition in the above-mentioned ratio is to use commercially available wheat flour, the wheat flour obtained by LTG-SD wheat prepared above, the wheat flour obtained by N61 wheat, the wheat flour obtained by waxy wheat and waxy corn starch, composed of the following table 3 (mass %)constitute.

[0143] In addition, in the test, the thin force powder Heart TM (manufactured by Nippon Milling Co., Ltd.) as commercially available wheat flour. The production process is as follows. The whole egg required for the experiment was broken up in advance and kept warm at 25°C. Add 125g of granulated sugar to 175g of whole eggs and mix with a mixer for 1 minute on low speed, 10 minutes on high speed, and 1 minute on low speed. Add the pre-mixed and sieved powder according to the composi...

Embodiment 3

[0175] cookie making

[0176] Cookies were prepared with the ingredients (parts by mass) shown below.

[0177] Wheat Flour 150

[0178] Fine grain 75

[0179] skimmed milk powder 5

[0180] salt 1

[0181] shortening 50

[0182] Baking soda 0.6

[0183] Ammonium bicarbonate 0.8

[0184] water 30

[0185] The wheat flour composition in the above-mentioned ratio is to use commercially available wheat flour, the above-mentioned modulated wheat flour obtained by LTG-SD wheat, wheat flour obtained by N61 wheat, wheat flour obtained by waxy wheat and waxy cornstarch, according to the composition in Table 5 ( mass%) constituted.

[0186] In addition, in the test, the thin force powder Heart TM (manufactured by Nippon Milling Co., Ltd.) as commercially available wheat flour. The production process is as follows. Combine required amounts of granulated sugar, skim milk powder, salt, shortening, baking soda, ammonium bicarbonate, water in a mixer and mix on low speed for 1 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com