Pressure device

A technology of pressing plate and driving device, which is applied in the direction of punching machine, press machine, manufacturing tool, etc., can solve the problems of manual tearing of anti-coating, time-consuming, waste of cost, and defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The pressing plate device provided by the technical solution will be further described in detail below in conjunction with the accompanying drawings.

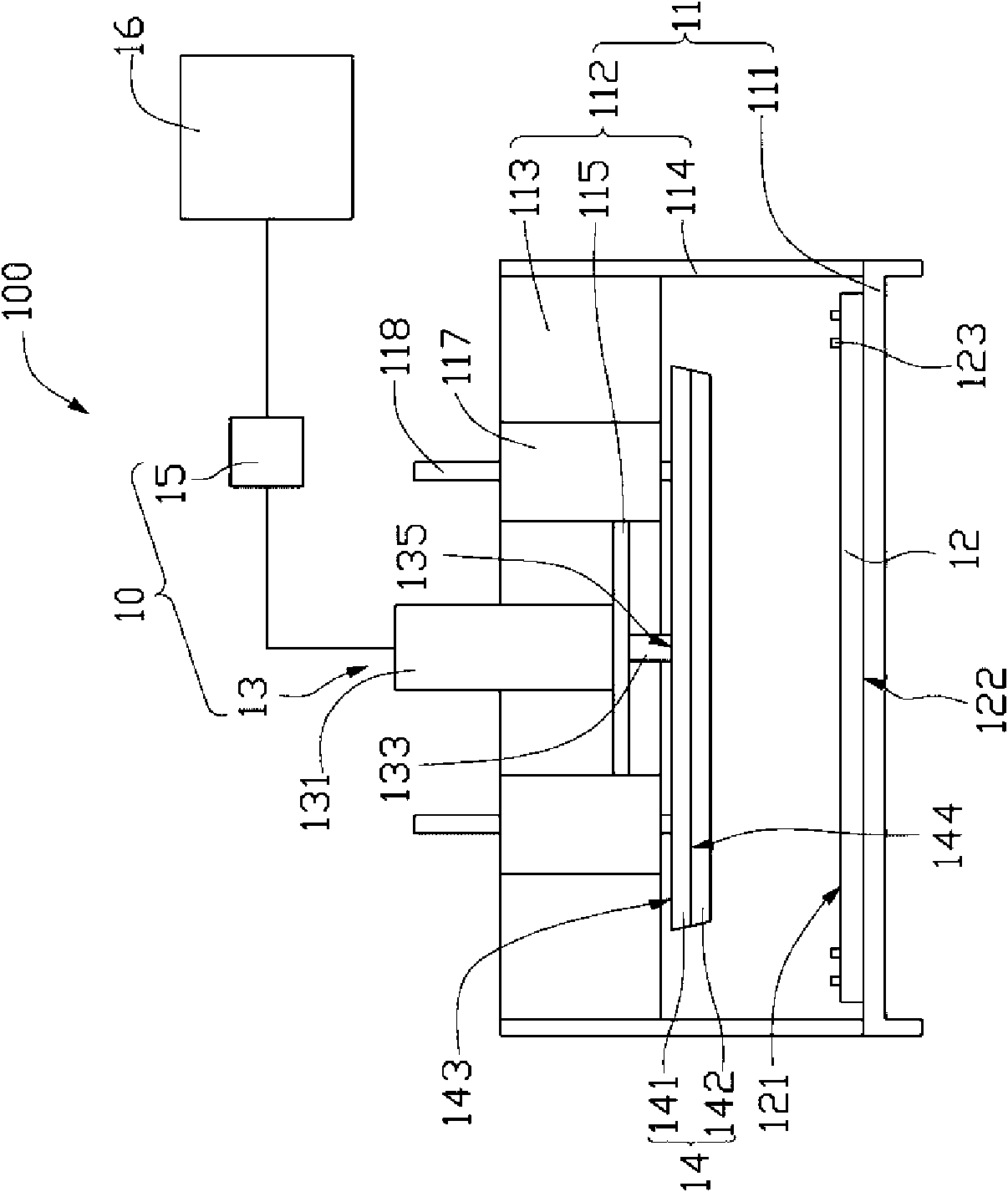

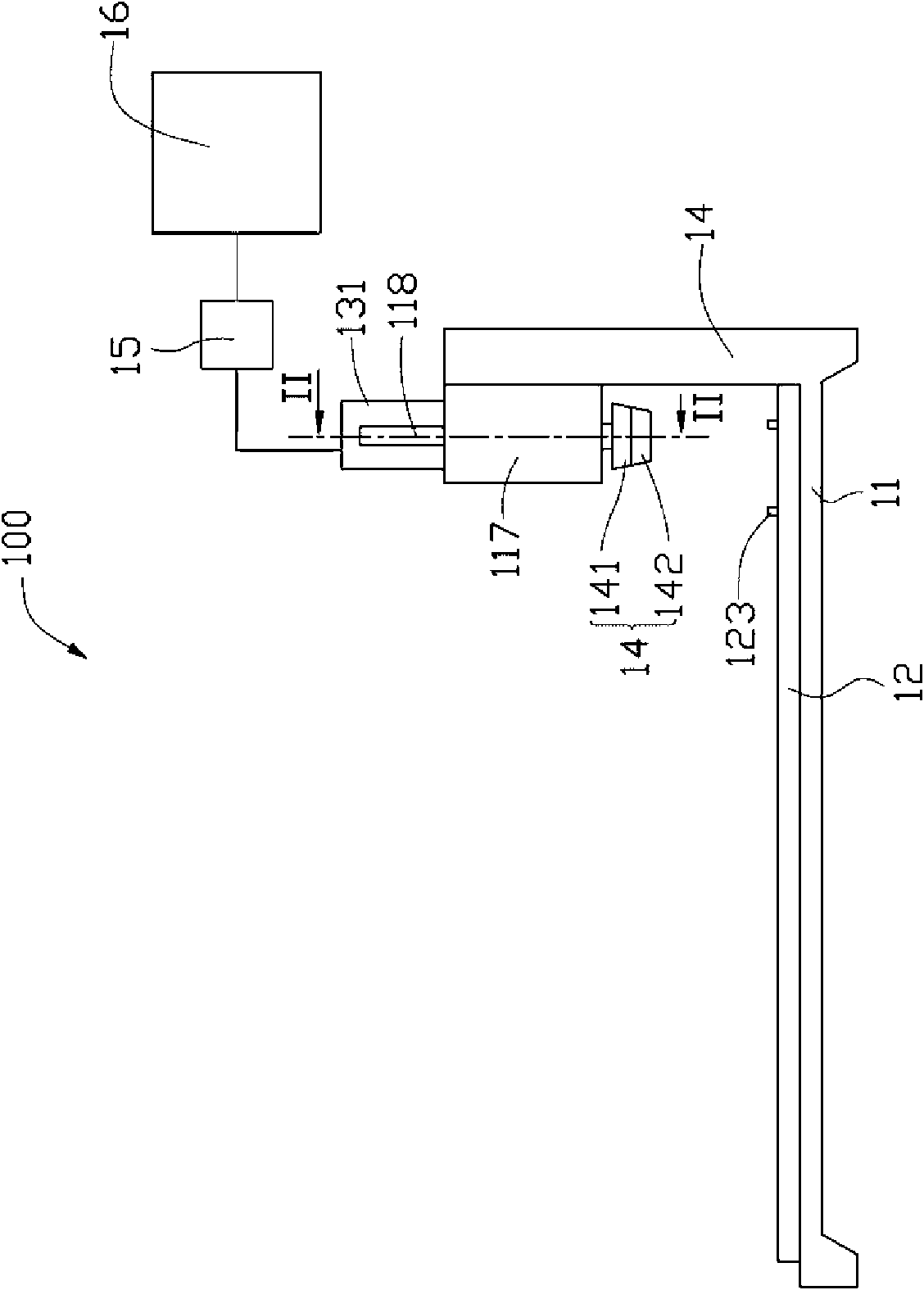

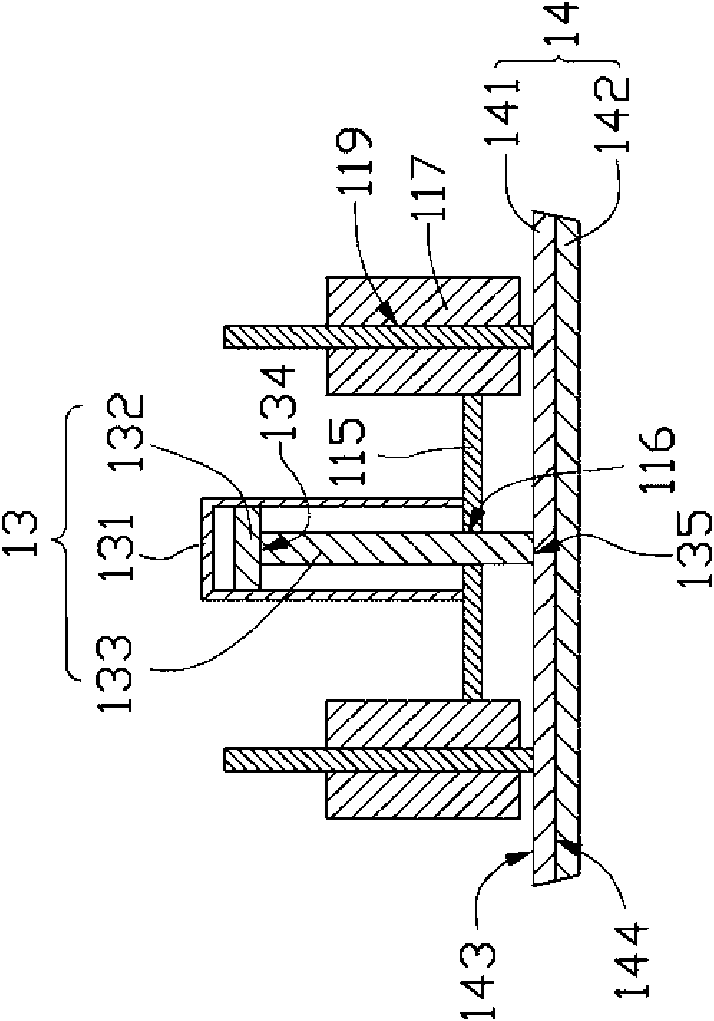

[0015] see figure 1 and figure 2 , Embodiment 1 of the present technical solution provides a platen pressing device 100 , which includes a frame 11 , a loading plate 12 , a driving device 10 , a holding member 14 , and a controller 16 . The frame 11 includes a stage 111 and a bracket 112, the carrier plate 12 is fixed on the stage 111, the driving device 10 is installed on the bracket 112, the holding member 14 is connected to the driving device 13, the controller 16 and The driving device 10 is connected to control the action of the driving device 13 to move the holding member 14 closer to or away from the supporting plate 12 .

[0016] The carrier 111 has a substantially rectangular carrying surface. The bracket 112 includes two support plates 114 , a holding plate 113 and a mounting base 115 . The two support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com