Printing press

A technology for printing machines and printing devices, applied to printing machines, printing, rotary printing machines, etc., can solve the problems of uncomfortable and unfavorable replacement, and achieve the effect of facilitating the replacement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

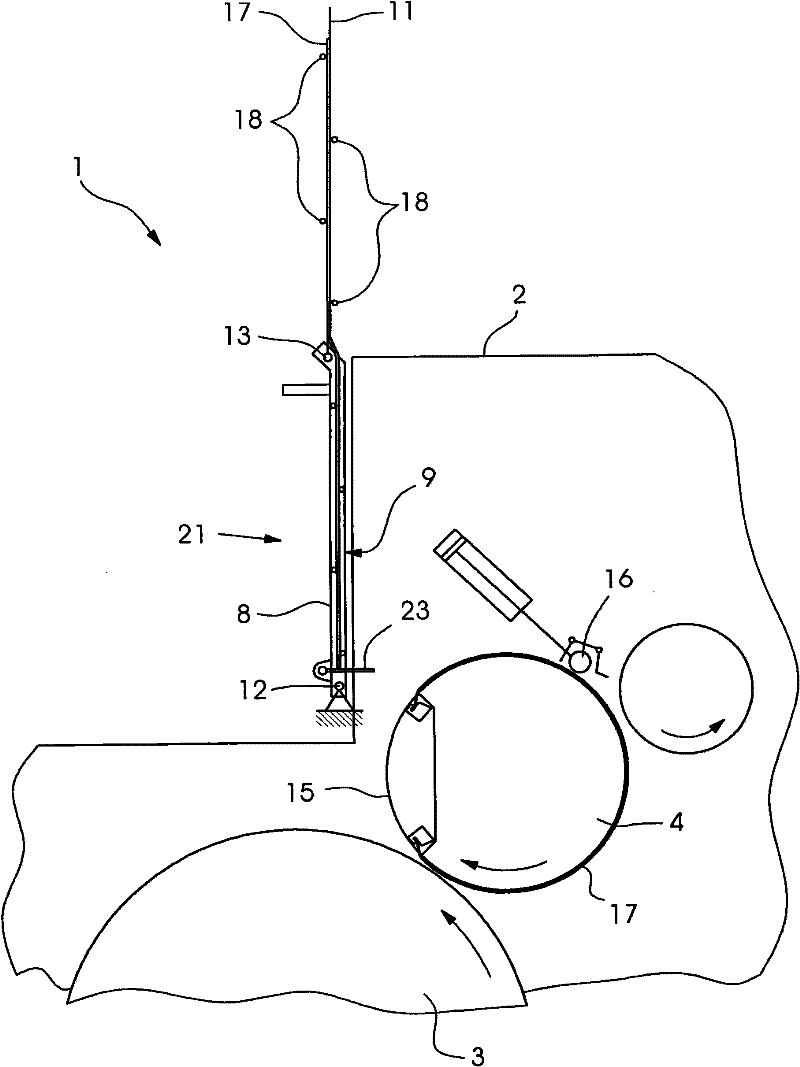

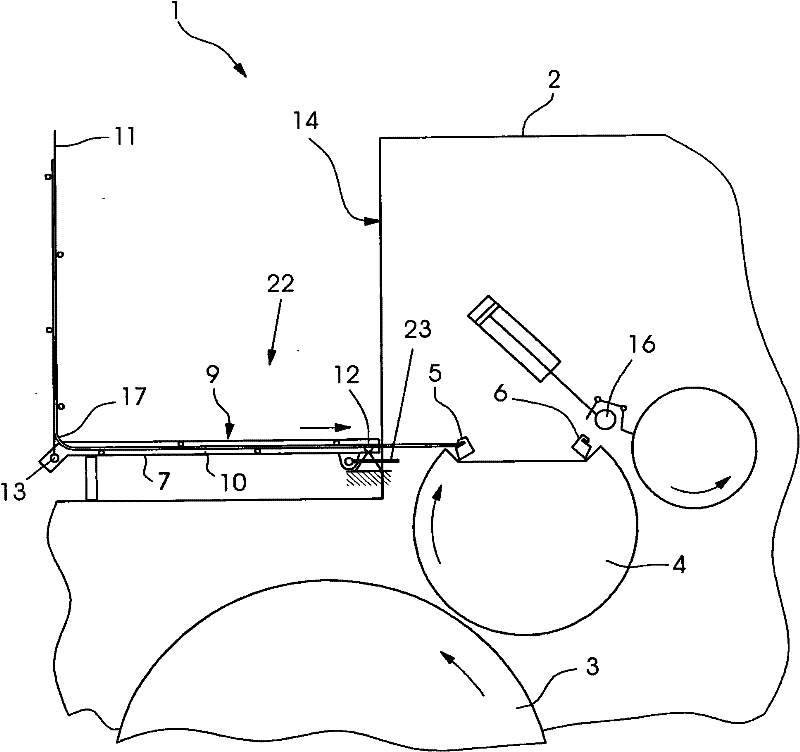

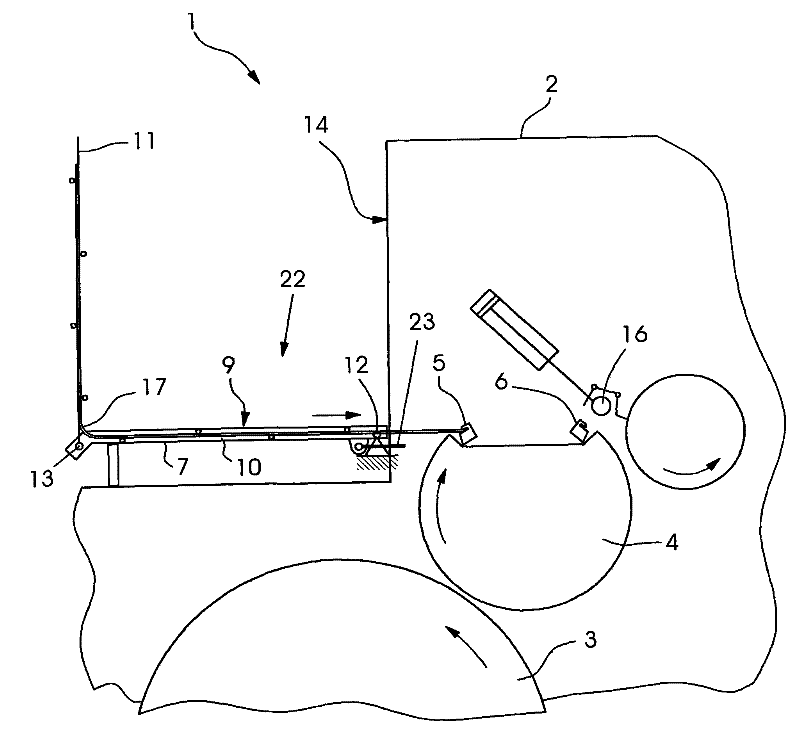

[0028] figure 1 and 2 A partial view of the printing press 1 is shown. This partial illustration shows the coating device 2 of the printing press 1 . The glazing device 2 comprises a counter cylinder 3 for conveying the printed sheets. Furthermore, the coating device 2 also includes a plate cylinder 4 , which cooperates directly with the counterpressure cylinder 3 .

[0029] The forme cylinder 4 is a so-called coating cylinder, which applies a varnish or similar coating liquid to the printed sheet. The plate cylinder 4 is equipped with a front holding device 5 and a rear holding device 6 . The front holding device 5 is used to fix the front end of a coating plate 18 which can be tensioned on the plate cylinder 4 in the direction of cylinder rotation, and the rear holding device 6 is used to hold the rear end of the plate. The holding devices 5 , 6 are clamping devices in which the edge of the plate is clamped. Glazing plate 17 can be flexographic printing plate, also can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com