Installation structure for circular knitting machine sinker triangular seat

A technology of installation structure and sinker, which is applied in weft knitting, textiles, papermaking, knitting, etc. It can solve the problems of inconvenient operation of circular knitting machines, and achieve the effect of easy threading and cleaning of cotton wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

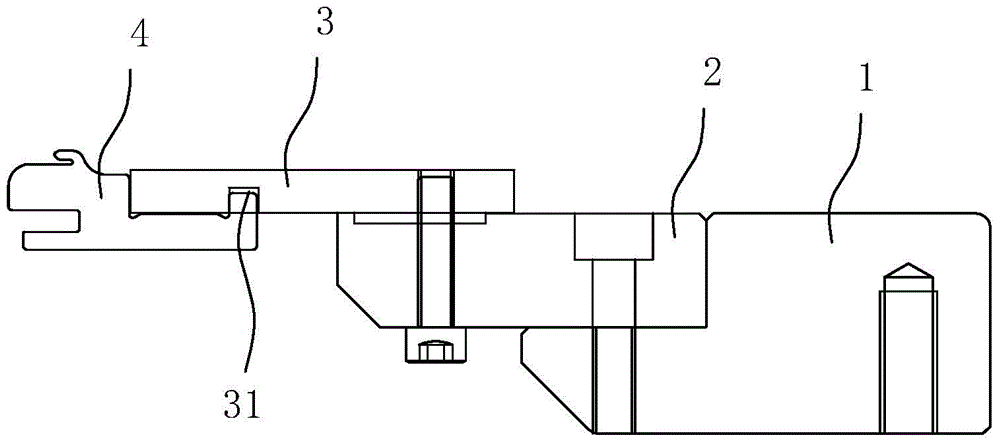

[0008] like figure 1 As shown, the installation structure of the sinker cam seat of a circular weft machine includes a circular seat 1, a mounting block 2 fixed on the circular seat 1, and a sinker cam seat 3 fixed on the mounting block 2, wherein the sinker The sheet 4 is slidingly fitted with the grooved track 31 of the triangular seat 3 . In the present invention, the cam base 3 is fixed on the upper side of the mounting block 2, and the top of the sinker cam base 3 is not lower than the top of the mounting block 2, that is, the top of the sinker cam base 3 can be higher than the mounting block 2. The top of the block 2, or the top of the sinker cam 3 is flush with the top of the mounting block 2. In this embodiment, the top of the sinker cam seat 3 is higher than the top of the mounting block 2, which is more convenient for the operator to observe the weaving mechanism.

[0009] Because the top of the cam base 3 of the present invention is not lower than the top of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com