Enclosed hood

A technology of airtight cover and rolling door, which is applied in the direction of solid separation, dust removal, filter and screen, etc. It can solve the problems of cumbersome installation, easy damage of airtight cover, inconvenient internal observation, etc., and achieve the effect of meeting the sealing requirements and being easy to open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

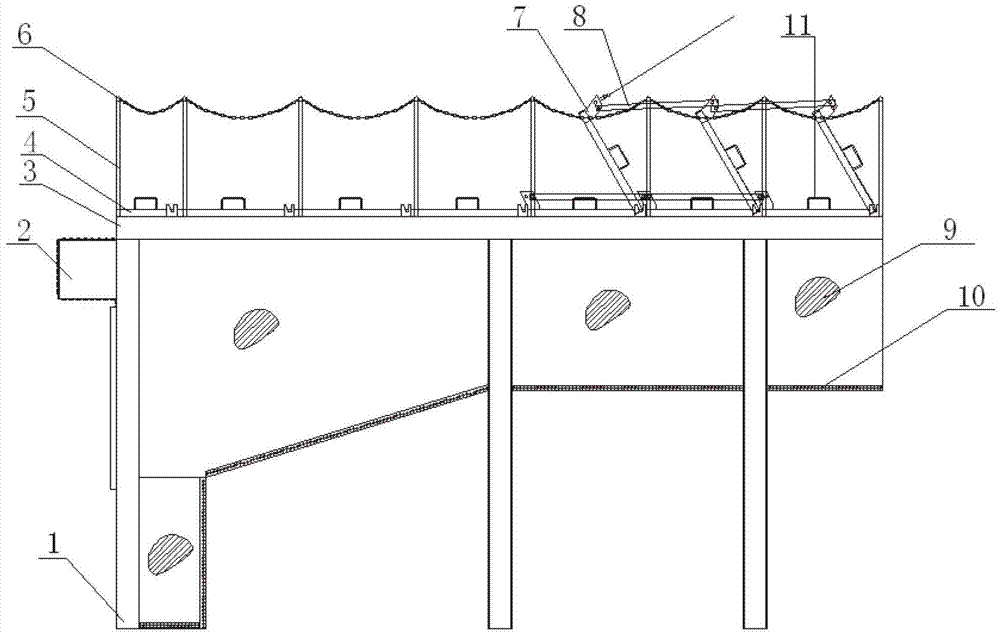

[0014] Such as figure 1 . An airtight enclosure is characterized in that it is welded into an airtight enclosure frame by uprights 1, beams 3 and angle steels 10, side panels 9 are welded on both sides of the airtight enclosure frame, and the rolling shutter door 2 at the front end of the airtight enclosure is electric. The rolling shutter door is used to observe the working condition of the vibrating screen, and it is also convenient for sealing and opening. The top of the airtight cover is provided with a top cover 4, the top cover 4 is arranged on the top of the beam 3, the top cover 4 is provided with a sight hole cover 11, and the sight hole cover 11 is provided with a louver 7 and a pull rod 8, and the louver 7 and the pull rod 8 pass through the hinge active connection. When the top inspection is required, only the sight hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com