Installation device for circular knitting machine sinker triangular seat

A technology for installing devices and sinkers, which is applied in weft knitting, textiles, papermaking, knitting, etc., can solve the problems of high machine cost, increased number of parts, consumables, etc., and achieve the effect of simple machine structure and reduced machine cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

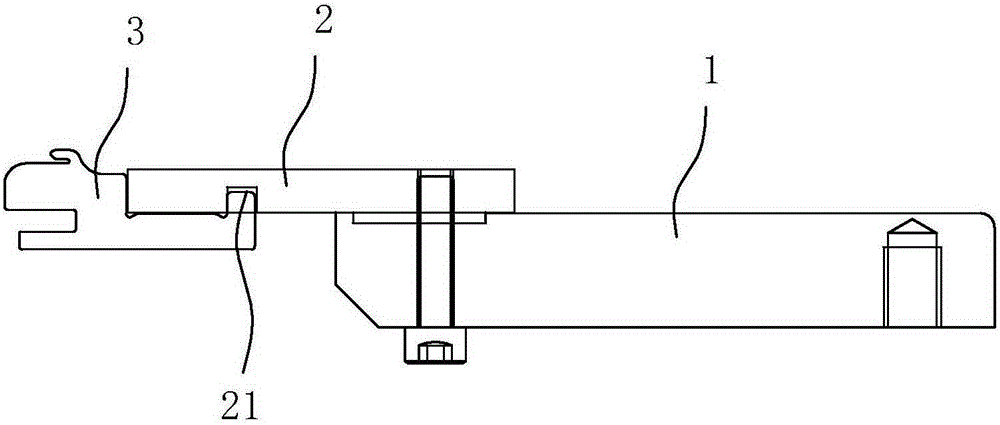

[0008] Such as figure 1 As shown, an installation device for a sinker cam seat of a circular weft machine includes a circular ring seat 1 and a sinker cam seat 2 , wherein the sinker 3 is slidingly fitted with the grooved track 21 of the cam seat 2 . In the present invention, the sinker cam seat 2 is directly fixed on the ring seat 1, and the top of the sinker cam seat 2 is not lower than the top of the ring seat 1, that is, the top of the sinker cam seat 2 Can be higher than the top of the ring seat 1, or the top of the sinker triangle seat 2 is flush with the top of the ring seat 1.

[0009] Because the top of the triangular seat 2 of the present invention is not lower than the top of the ring seat 12, the triangular seat 2 has adopted a floating installation. Compared with the traditional sunk installed triangular seat, when the circular weft machine is carried out in a conventional operation, The circular seat 1 will not block the triangular seat 2, and the operator can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com