Full-fabricated high-ductility anti-buckling support

A buckling-resistant support and high-ductility technology, which is applied in the direction of earthquake-proof, protective buildings/shelters, and building components, can solve the problems of failure to quit work due to fracture, complex structure, and insufficient ductility, etc., and achieves the convenience of observing damage and replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

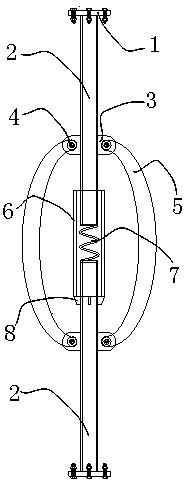

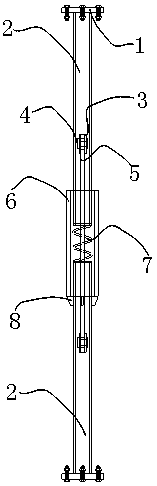

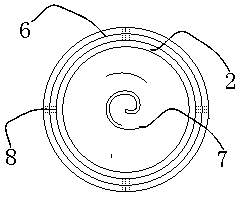

[0019] Such as Figure 1-3 Shown: a fully assembled high-ductility buckling-resistant brace, which includes two axial force-transmitting steel pipes 2, node connection end plates 1, pin lug plates 3, pin shafts 4, and curved energy-dissipating steel plates in the arched plane 5 , the middle steel casing 6, the reset reaction force spring 7 and the positioning stiffening steel plate 8; the reset reaction force spring is rigidly connected between the two axial force transmission steel pipes, the reset reaction force spring and the axial force transmission connected to its two ends The two ends of the steel pipe are located in the middle steel casing and can slide relatively; the pin lugs are respectively welded on both sides of the middle of the two axial force transmission steel pipes, and the two ends of the curved energy-dissipating steel plate in the arched surface pass through the pin It is hinged on the pin lug plates of two axial force transmission steel pipes, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com