Agricultural tricycle

A technology for tricycles and agriculture, which is applied to vehicle parts, vehicles with tilted bearing motion, control devices, etc. It can solve the problems of short service life, no self-unloading device, inconvenience for users, etc., and achieve long service life, low cost, and improved The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

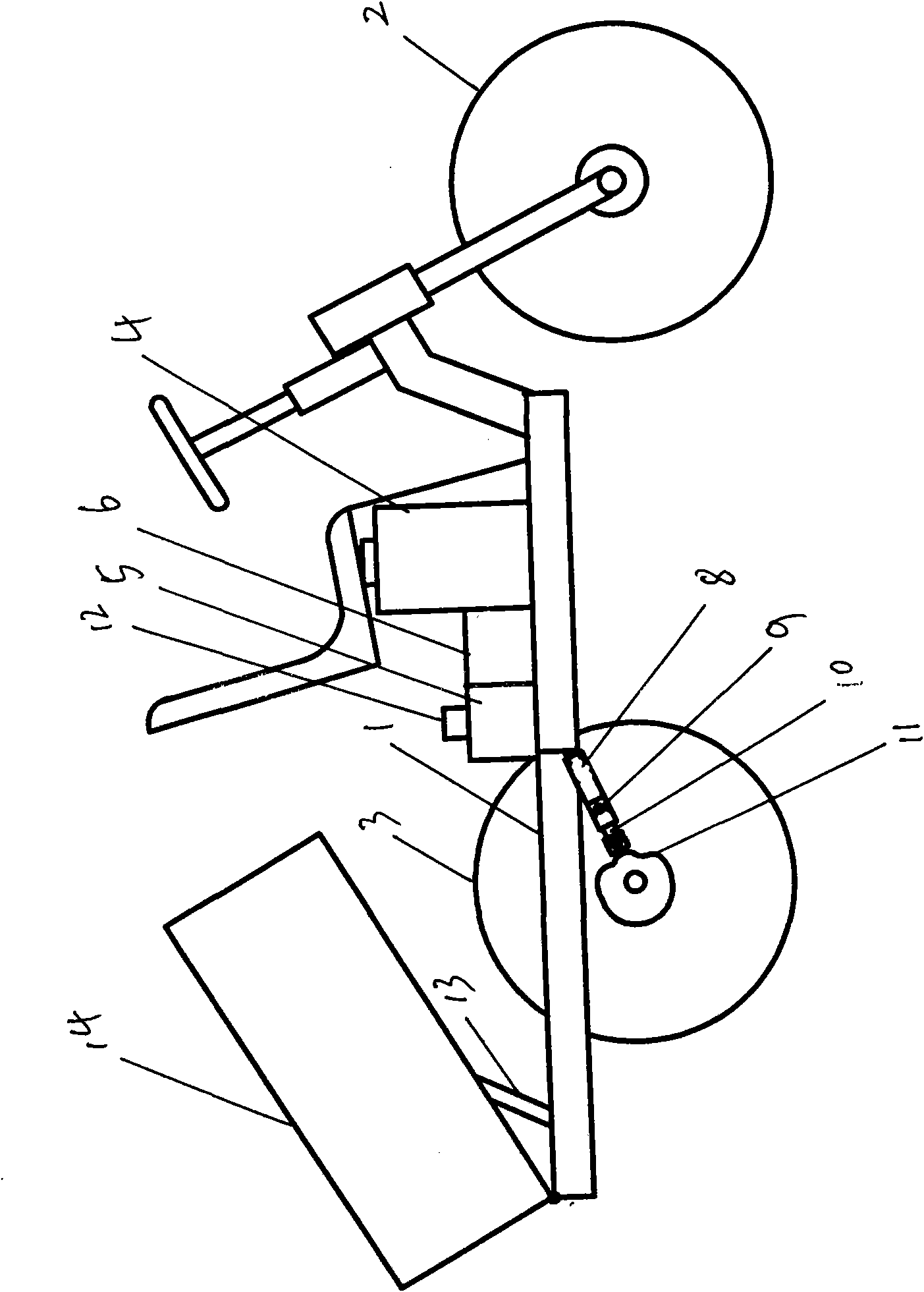

[0009] control figure 1 As can be seen, the present invention comprises a crossbeam 1, a front wheel 2, a rear wheel 3 and a cargo box 14, the front wheel 2 is one, and the rear wheel 3 has two, and a diesel engine 4, a clutch 6, a gearbox 5 and a hydraulic pressure are installed on the crossbeam 1. Tipper.

[0010] The diesel engine 4 is horizontally installed on the girder, the clutch 6 is fixedly installed on the flywheel of the diesel engine, the input shaft of the gearbox 5 is connected with the clutch 6, the output shaft 8 of the gearbox 5 is connected with the universal joint 9, the transmission shaft 10 and the rear axle Assemblies 11 are sequentially connected.

[0011] The hydraulic self-unloading device includes a hydraulic oil tank installed on the girder, a hydraulic top (not shown in the figure), and a high-pressure gear pump 12 installed on the gearbox. The hydraulic oil tank is connected to the high-pressure gear pump through an oil inlet pipe ( Not marked), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com