Variable incidence scramjet engine outboard cowl

A scramjet and engine technology, which is applied in ramjet engines, mechanical equipment, etc., can solve problems that have not yet been consulted, and achieve the effects of being beneficial to voyage, reducing pressure differential resistance, and reducing shock wave resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

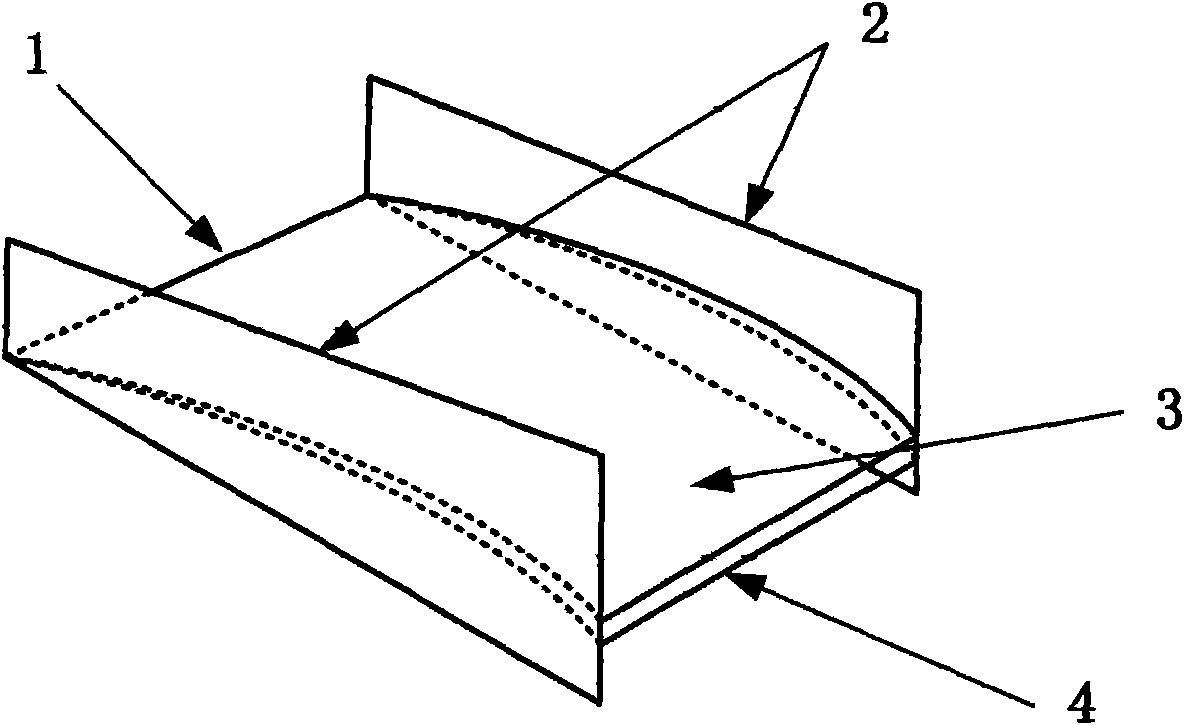

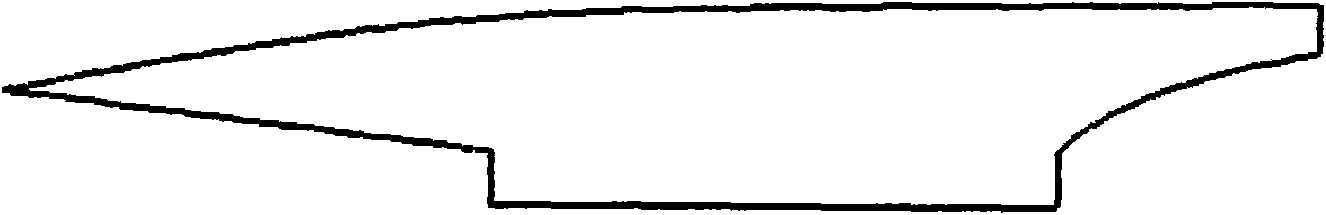

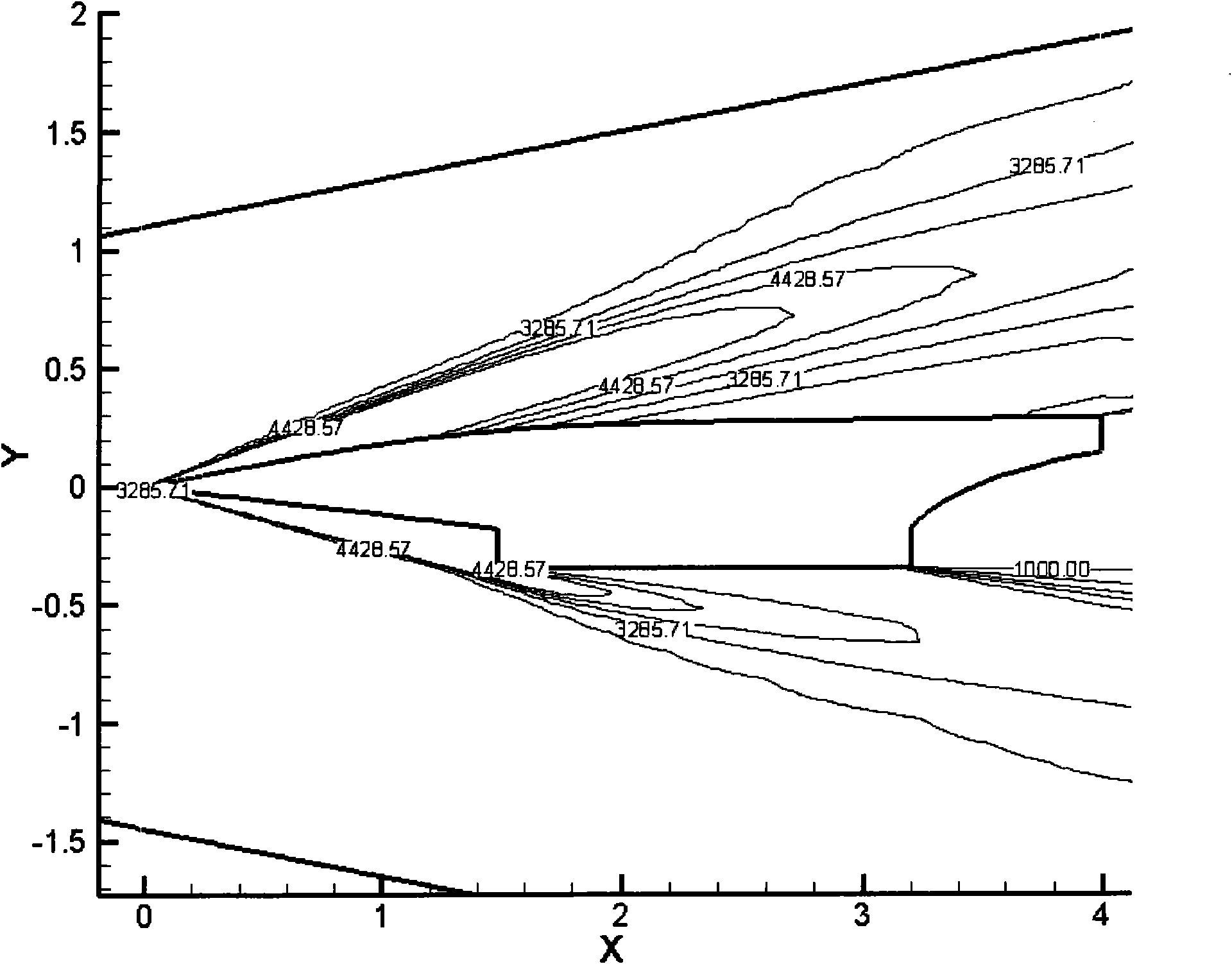

[0024] like figure 1 As shown, the scramjet outer fairing with variable inclination angle includes side wall 2 and fixed lower wall surface 3, side walls 2 are arranged on both sides of fixed lower wall surface 3, and the rotary shaft arranged on its lip under fixed lower wall surface 3 1 is hingedly connected with an adjustable lower wall surface 4, the adjustable lower wall surface 4 is powered by a driving mechanism to deflect around the rotary shaft 1, and the deflection position of the adjustable lower wall surface 4 is defined by a limit locking mechanism.

[0025] like Figure 5 As shown, the side wall 2 is provided with a guide rail 21, and the adjustable lower wall surface 4 is provided with a sliding guide rod 41 that can slide in the guide rail 21. The lower wall surface 4 and the fixed lower wall surface 3 are connected by a spring-pull device 5, the spring-pull device 5 can eject or pull up the adjustable lower wall surface 4 downwards or upwards, and the spring-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com