Backlight module structure

A technology of backlight module and light guide plate, applied in optics, nonlinear optics, instruments, etc., can solve the problems of difficult positioning, broken holes, inconvenient assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the attached drawings, and the embodiments listed in the following drawings are only for auxiliary explanation, to facilitate understanding, but the technical means of the present invention are not limited The diagrams listed.

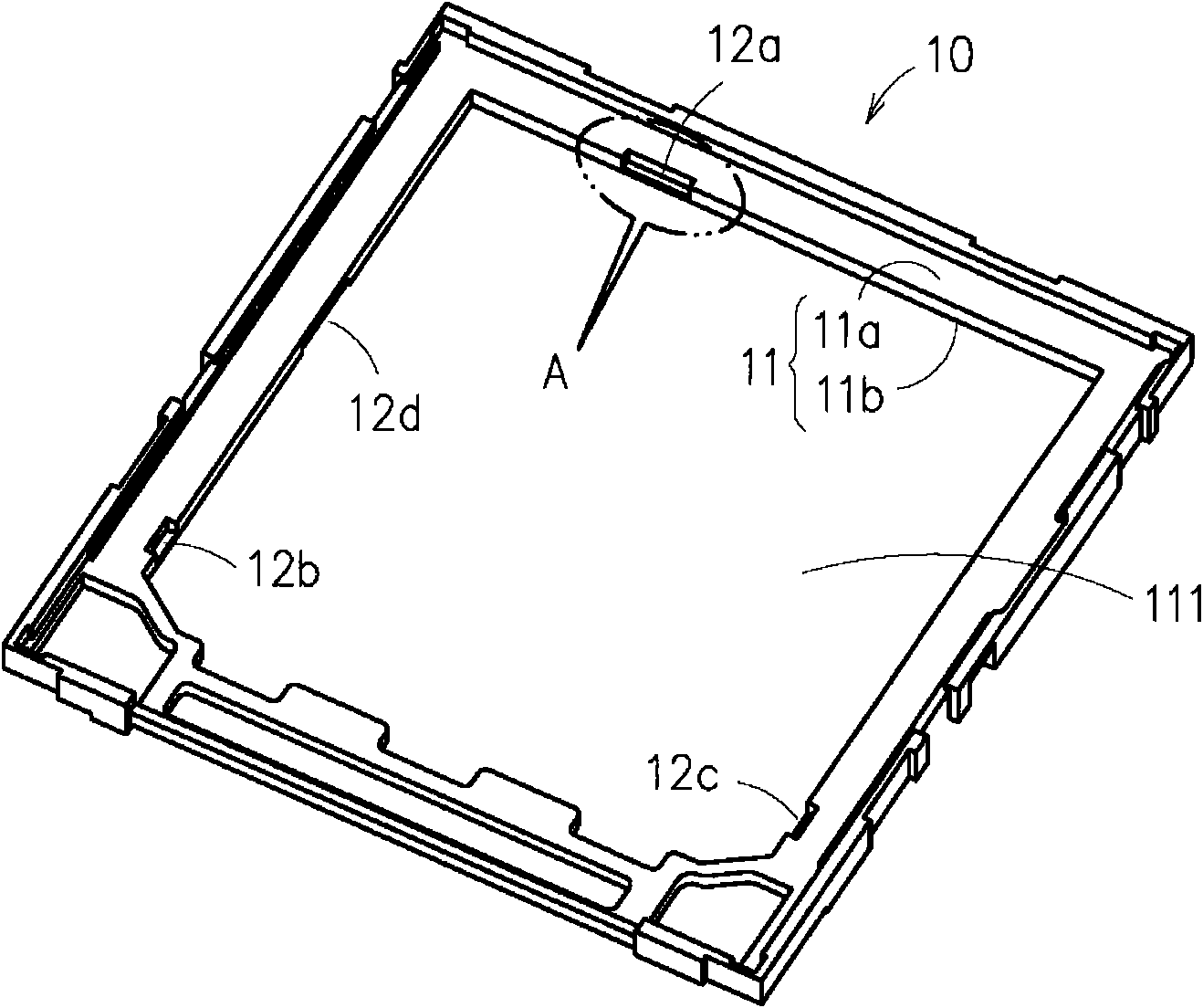

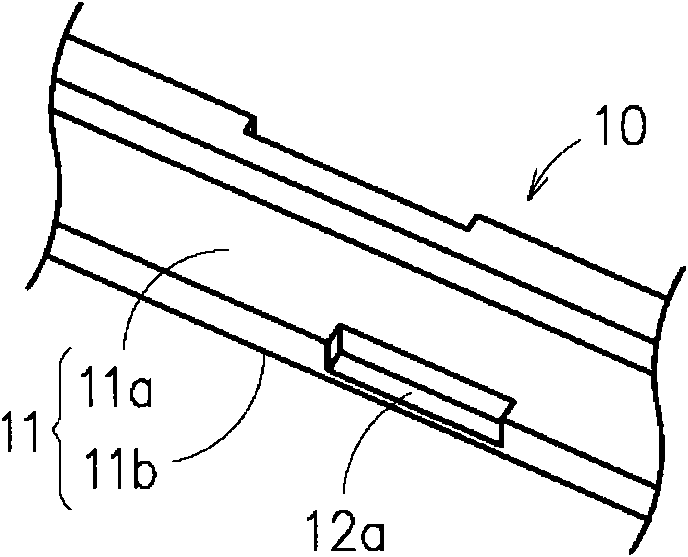

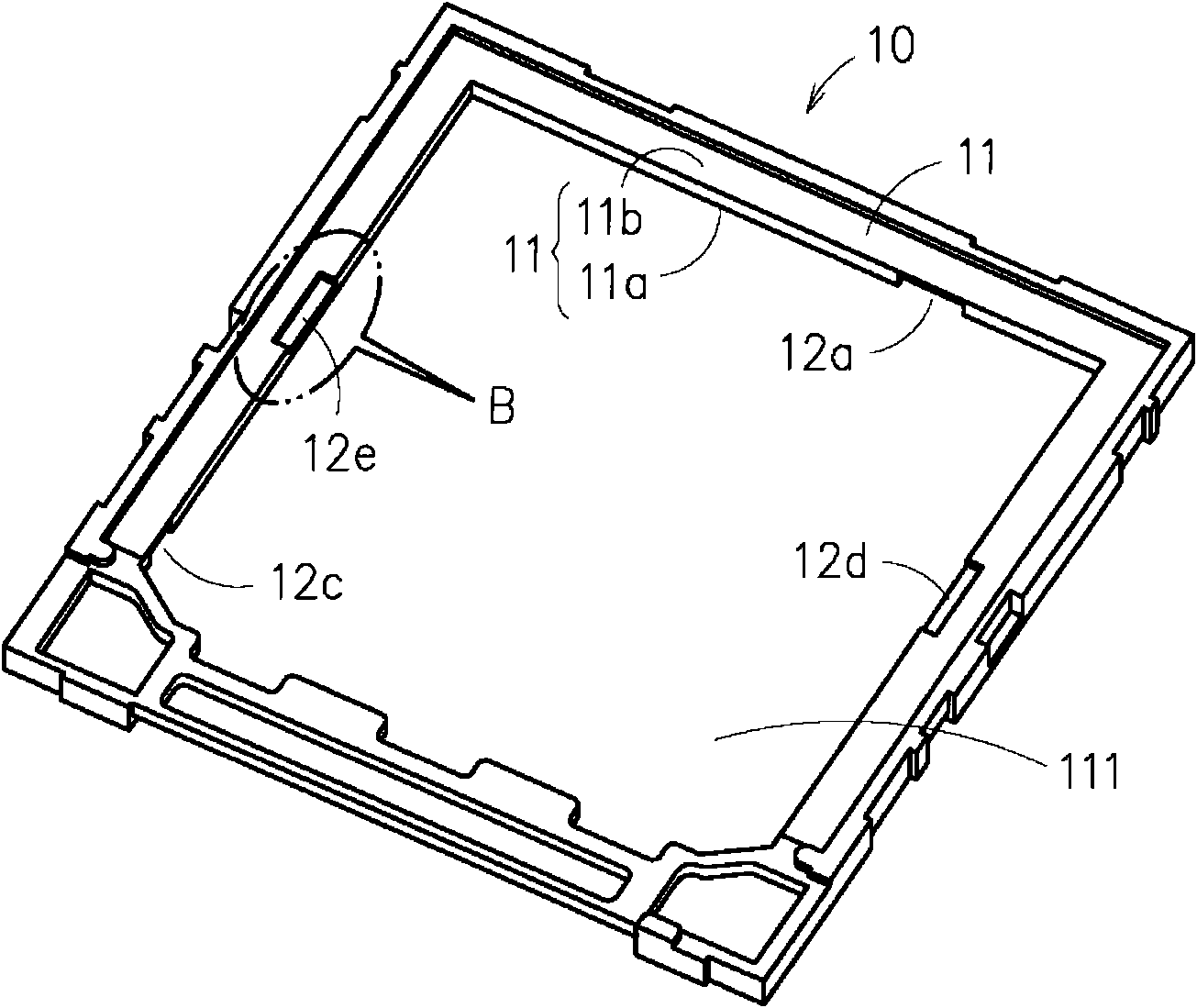

[0062] See first Figure 9 to Figure 12 As shown, the backlight module structure proposed by the present invention includes a frame 30, the frame 30 has a bearing portion 31, the bearing portion 31 has a front 31a and a back 31b, wherein the front 31a is used to directly carry a liquid crystal display Module (not shown in the figure), the bearing part 31 has a generally rectangular accommodation hole 311, and the periphery of the accommodation hole 311 is provided with a plurality of flanges 32a-32d, and a plurality of grooves 32e, 32f, and the flange 32a-32d and the grooves 32e, 32f are misaligned with each other; in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com