Miniature motor

A motor, small technology, applied in the direction of DC commutator, mechanical energy control, electric components, etc., can solve the problems of effective magnetic flux reduction, not easy to bend, and winding space to ensure obstacles, so as to ensure effective magnetic flux and prevent Winding hook hooked to the bending part, mechanical noise and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

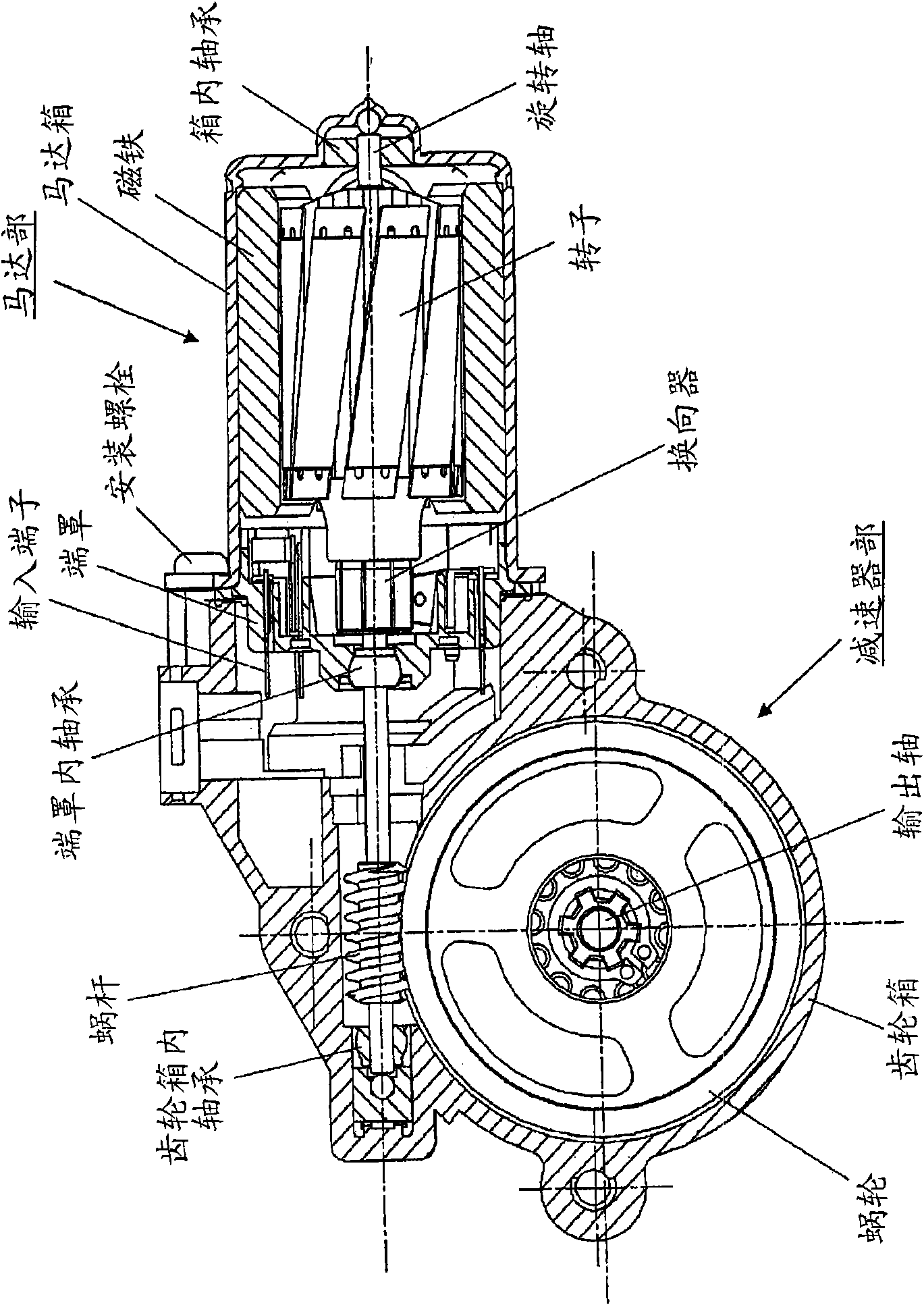

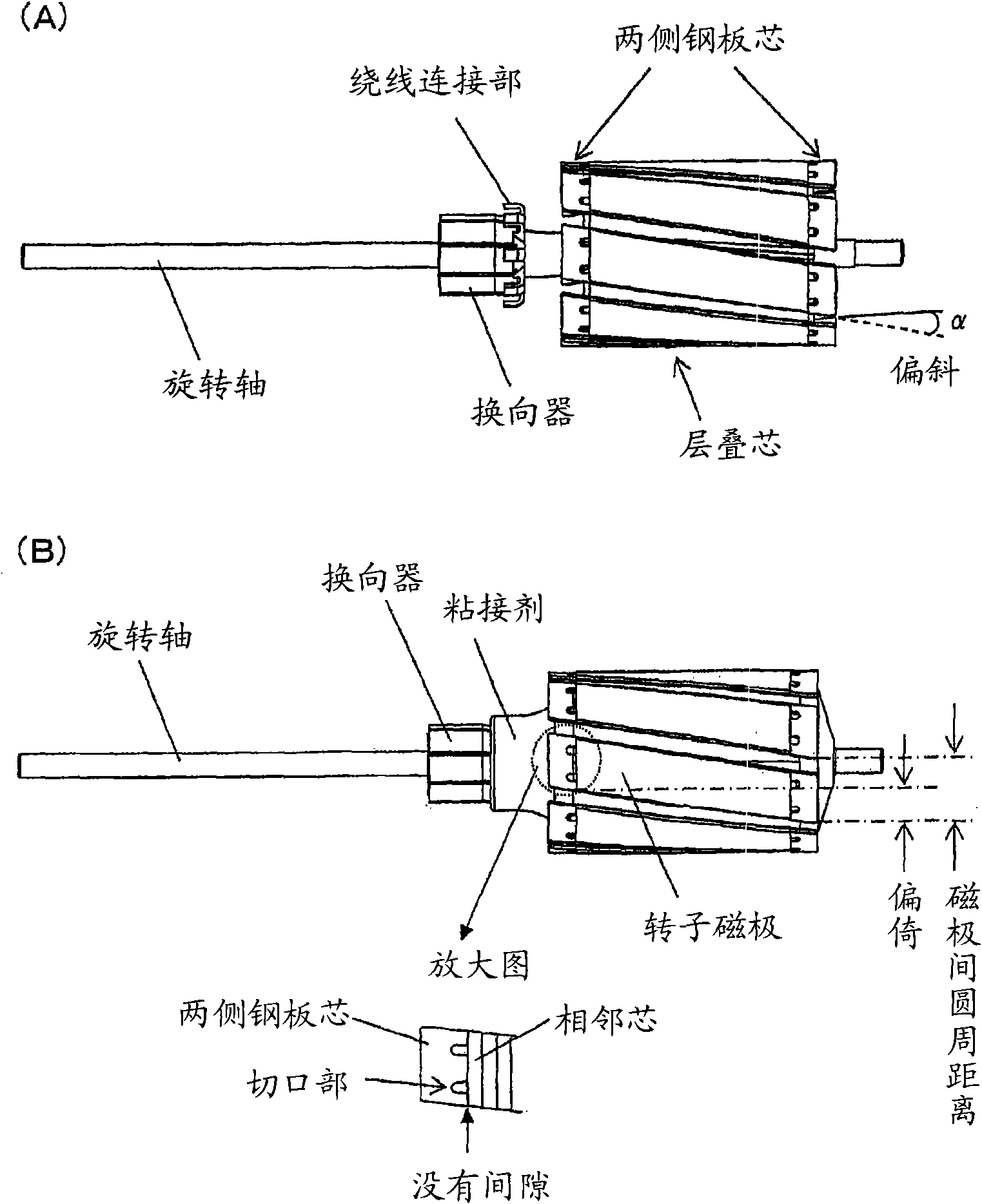

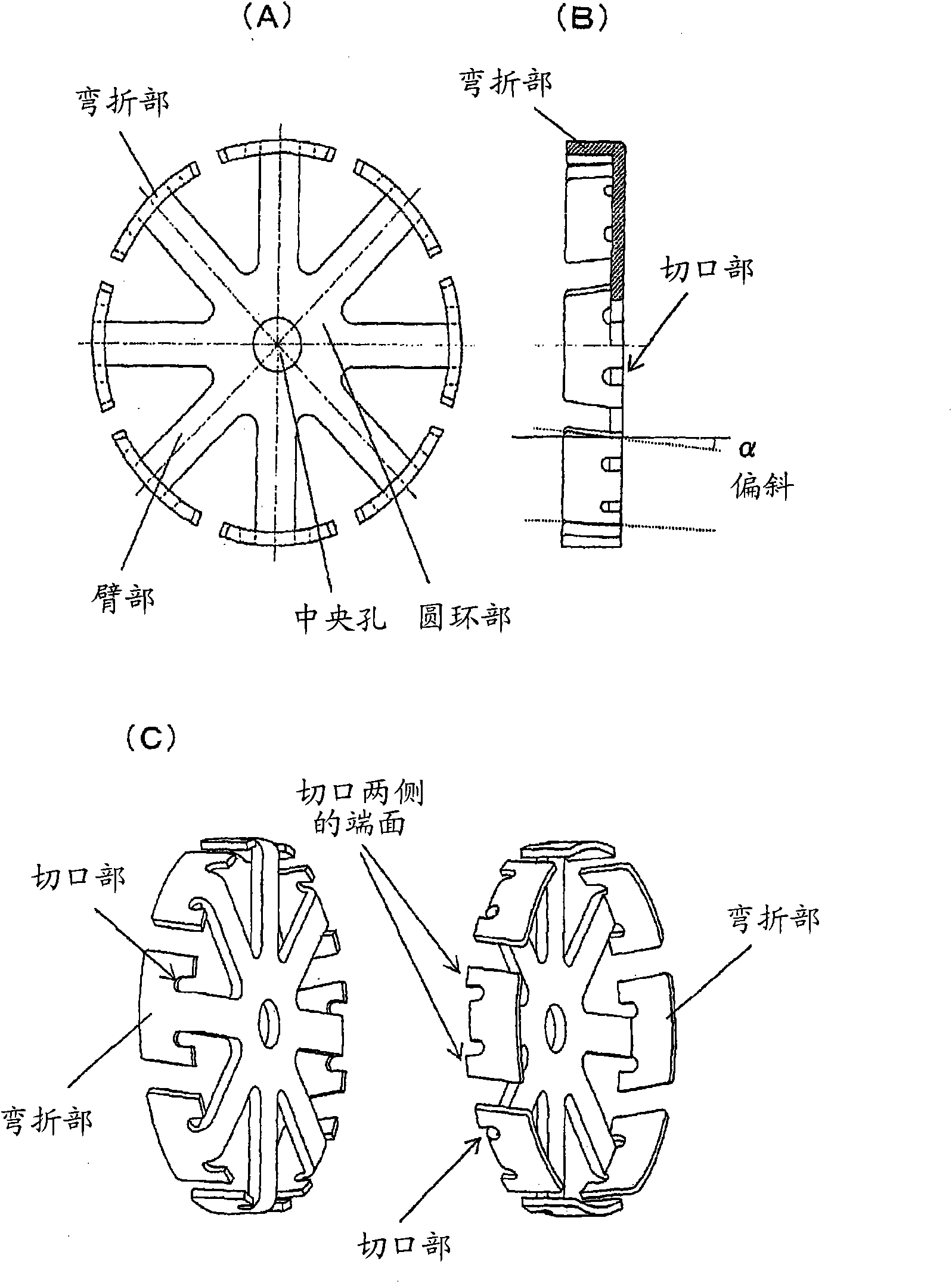

[0027] Hereinafter, the present invention will be described based on examples. figure 1 It is a longitudinal sectional view of a motor with a speed reducer constructed based on the present invention. This motor with a speed reducer has a structure in which a motor part and a speed reducer part are integrally assembled. The motor unit has a magnet attached to the inner peripheral surface of a bottomed hollow cylindrical motor case made of a metal material. The opening of the box is fitted with a resin end cover (Endbell) to close it. The rotating shaft is equipped with rotating magnetic poles and commutators composed of laminated cores wound with windings to form a rotor (see figure 2 ). In addition, a pair of input terminals connected to a pair of brushes contacting the commutator protrude outside the motor through the end cover for electrical connection. One end of the rotating shaft is supported by an in-box bearing provided at the bottom center of the bottomed hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com