Speed retarder of proportional valve control pump type medium and low power vehicle

A technology of small and medium power, proportional valve, applied in the direction of brake type, hydraulic brake, mechanical equipment, etc., can solve the problems of high manufacturing and installation cost, unfavorable programmed control of retarder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

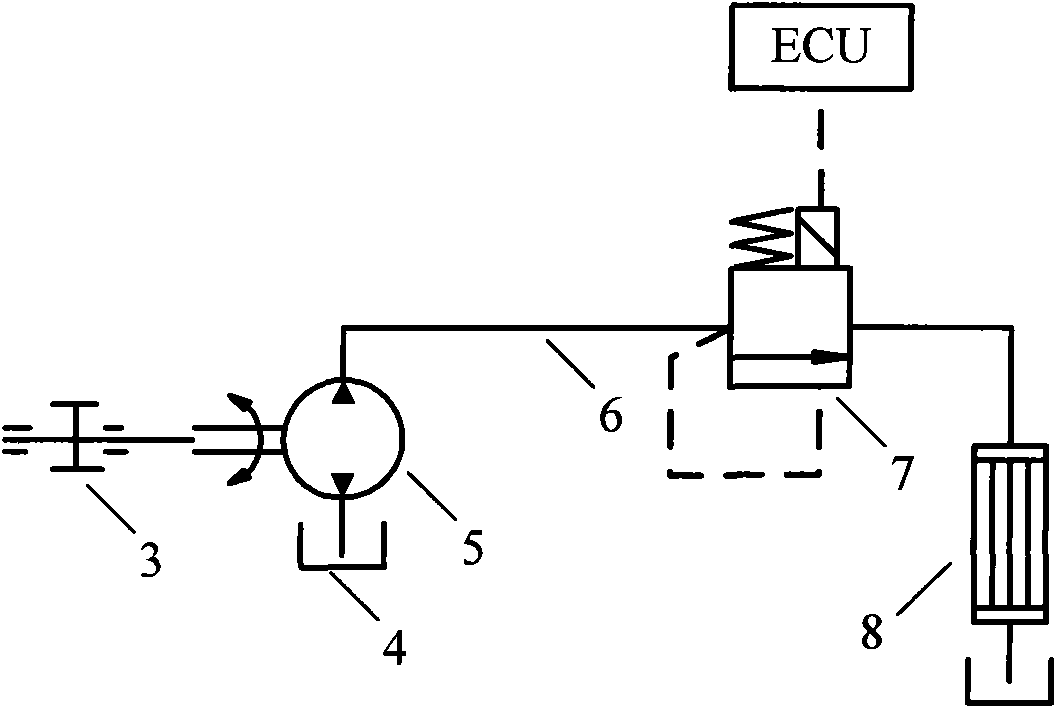

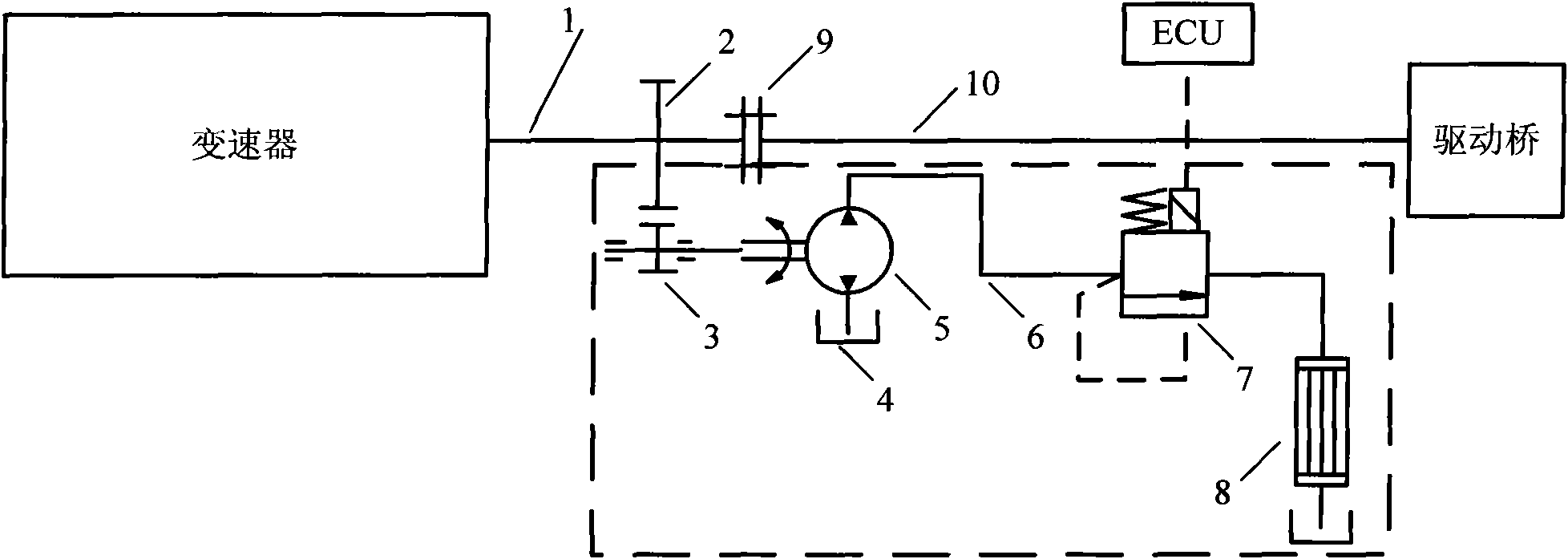

[0012] Such as figure 1 As shown, a proportional valve-controlled pump type retarder for medium and small power vehicles, a hydraulic pump driving gear 3, a hydraulic pump 5, the inlet of the hydraulic pump 5 is connected to the fuel tank 4, the rotor of the hydraulic pump 5 is connected to the hydraulic pump driving gear 3-axis mechanical connection; a proportional relief valve 7, the proportional relief valve 7 is electrically connected to the ECU, and connected to the outlet of the hydraulic pump 5 and the heat exchanger 8 through a hydraulic pipeline; the hydraulic pump 5 is a displacement of 250ml / r high-pressure hydraulic pump; proportional relief valve 7 is a high-pressure proportional relief valve with a pressure regulating range of 0-40MPa; hydraulic pump 5, proportional relief valve 7 and heat exchanger 8 are arranged in series, with hydraulic oil passages in between .

[0013] Such as figure 2 As shown, the present invention utilizes a hydraulic pump drive gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com