Mobile double-barrel straw solidification fuel forming machine

A solidified fuel and mobile technology, which is applied in the direction of material forming presses, biofuels, waste fuels, etc., can solve the problems of high friction between the outer cylinder and extrusion rollers, increased production costs, and short service life. The effect of reducing the degree of wear, prolonging the service life and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

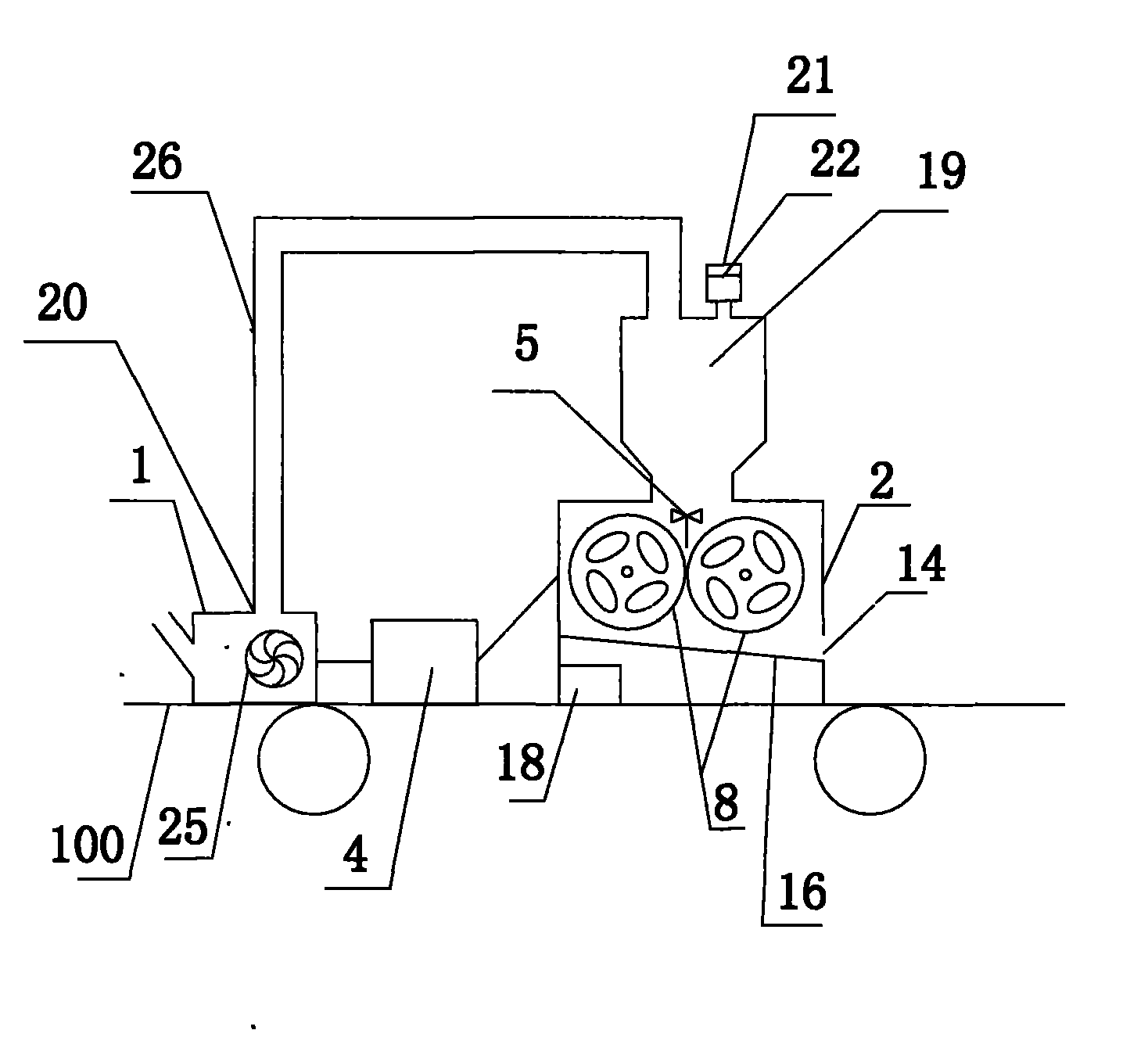

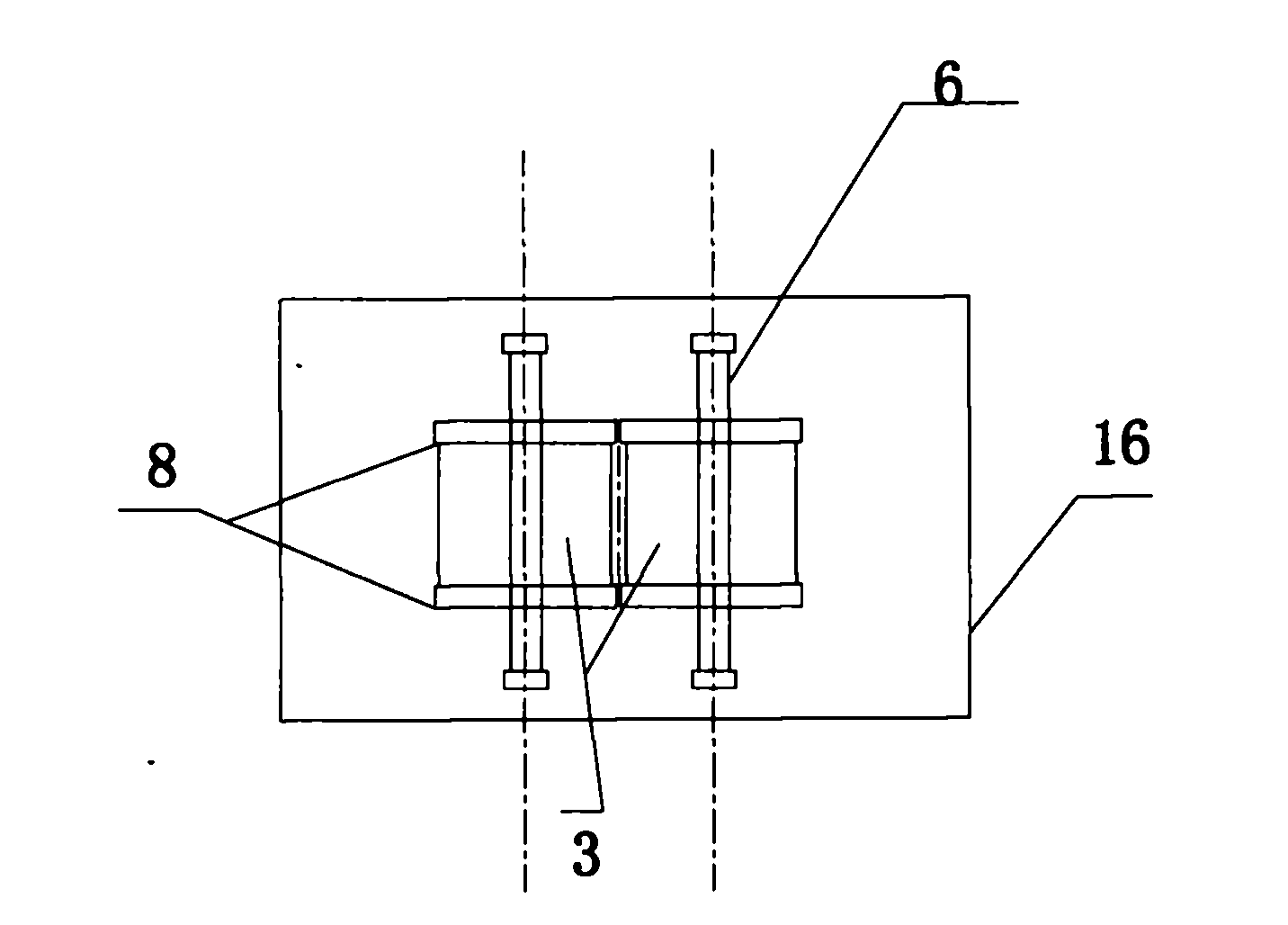

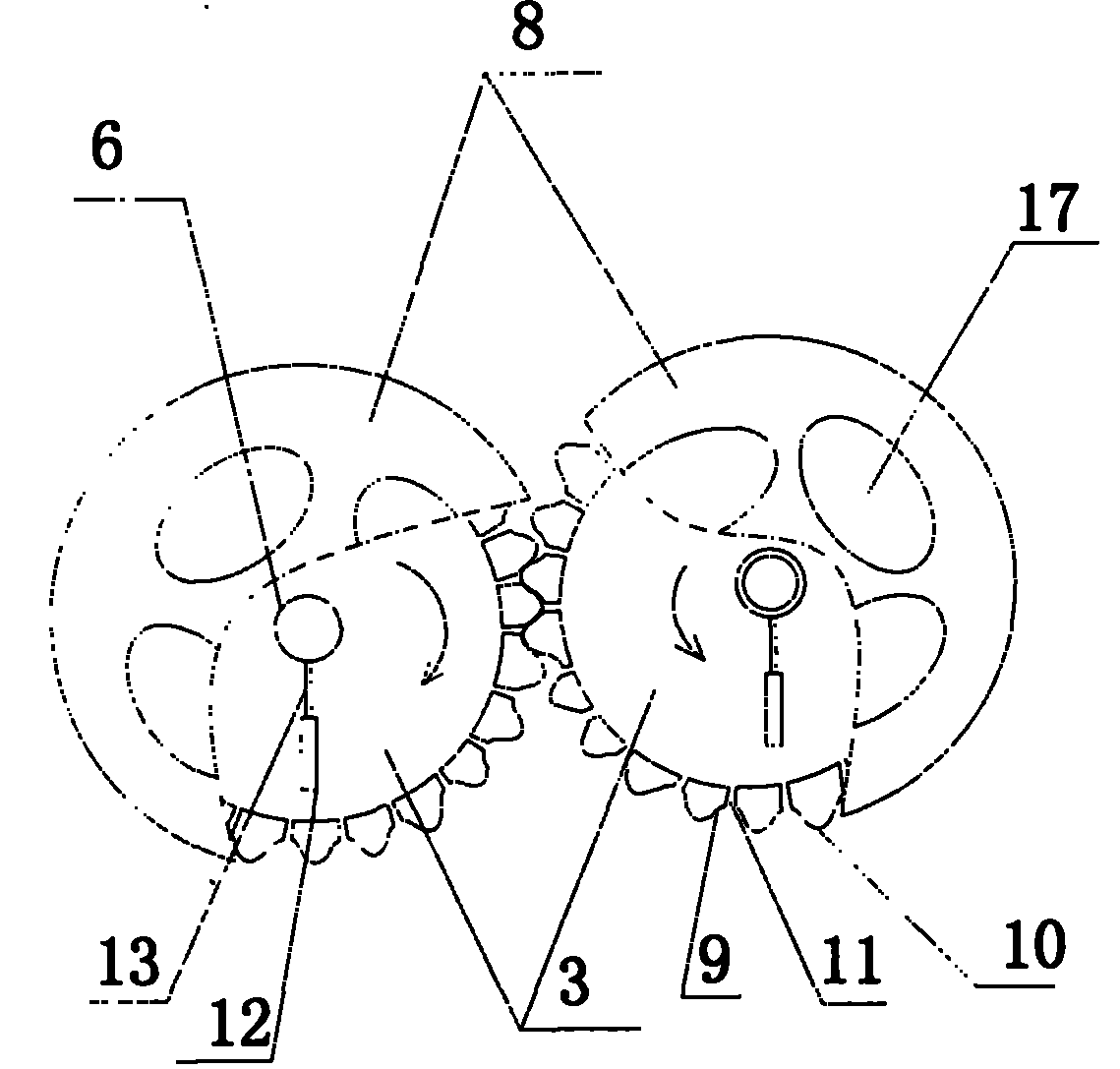

[0019] Such as figure 1 , figure 2 with image 3 As shown in , a mobile double-barrel solidified fuel molding machine includes a shredder 1 and an extruder 2 that are matched with each other. The extruder includes a shell, and a pair of front and rear extruders are arranged in the shell. The pair of material rollers 3, the front and rear rollers are provided with several extrusion through holes 11. The pulverizer and the extruder are installed on the frame 100 of the same motor vehicle, and the diesel engine 4 is also installed on the frame, and the diesel engine is respectively connected to the pulverizer and the extruder through a plurality of transmission mechanisms. The extrusion counter-rolls of the press, the vibrating screen 16 of the press and the drive system of the motor vehicle. Driven by a diesel engine, the stalks are crushed by a pulverizer, squeezed by the pair of rollers of the extruder, and then come out of the extrusion hole to form.

[0020] The front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com