Electric furnace sponge iron hot charging device and method thereof

A technology of sponge iron and hot charging, which is applied to electric furnaces, furnaces, furnace types, etc., to achieve the effects of reducing energy loss, good application prospects, and saving operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

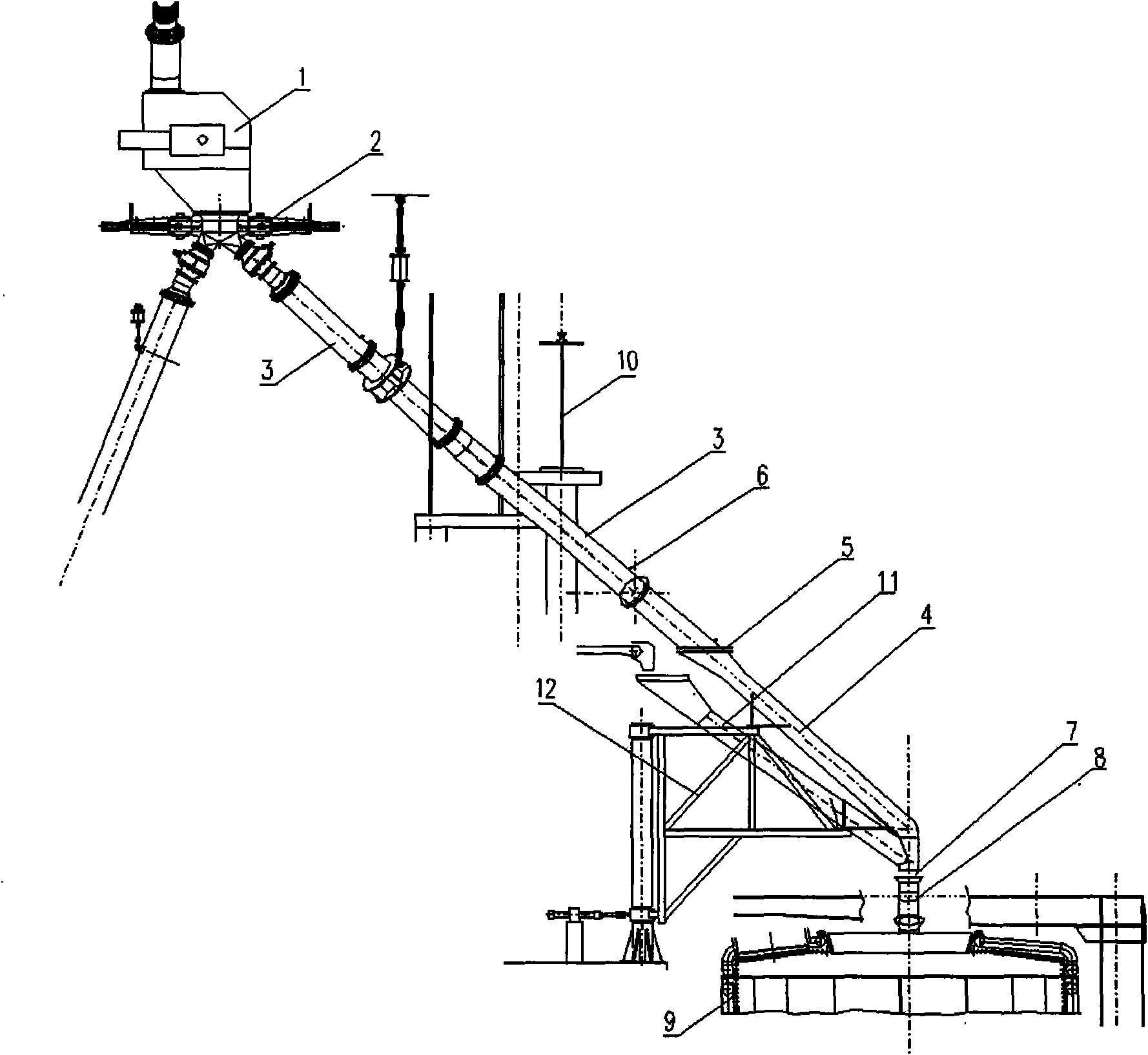

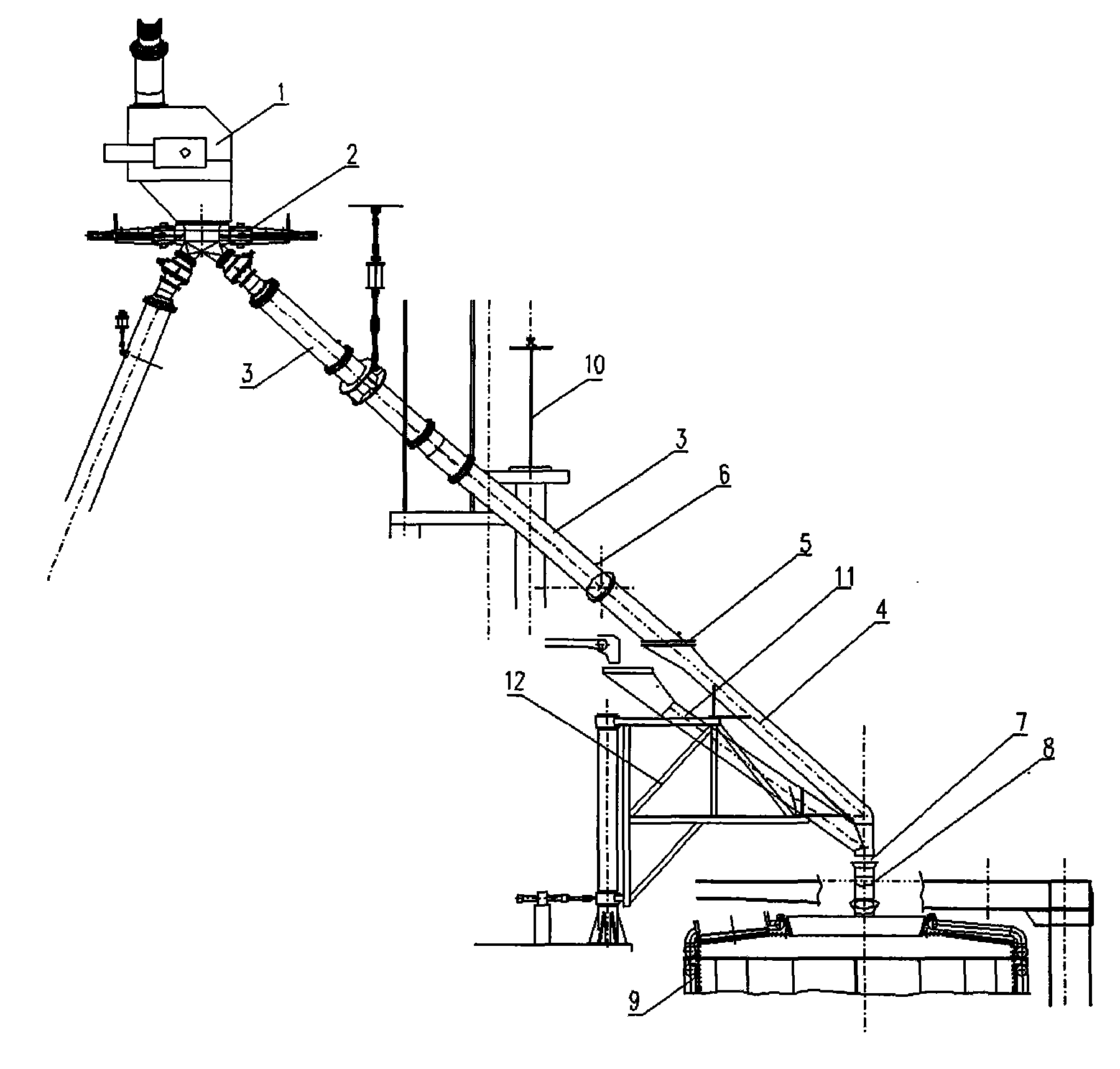

[0013] The device includes a transition tank, a distributor, a fixed chute, a heat-packed rotary chute, a nitrogen sealing device, a nitrogen cooling system, and a receiving chute. The fixed slide pipe 3 is located below the distributor 2 and directly enters the electric furnace workshop, and is respectively fixed by the hanger or bracket on the platform and the crane beam. An ordinary slide pipe 11 is also arranged on the pipe 4, which is used to meet the needs of adding fluxes such as lime and ferroalloy; The ends are aggregated into one chute to form a feeding chute similar to a tee; the receiving chute 8 is fixed on the furnace cover to receive hot sponge iron and lime, dolomite and other bulk material fluxes for smelting in electric furnaces ; The first nitrogen sealing device 5 is located between the fixed slide pipe 3 and the shrink-fit rotating slide pipe 4 . The second nitrogen sealing device 7 is located between the thermal charging rotary chute 4 and the fixed rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com