Safe grid plate without continuous frames

A grid plate, safe technology, applied in the direction of pedals, drainage structures, buildings, etc., can solve the problems of unsatisfactory economic and practical angle, accumulation of garbage or pollutants, and poor drainage and drainage on the ground. Remarkable economy, strong safety, ensure the effect of safe production and environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 Universal

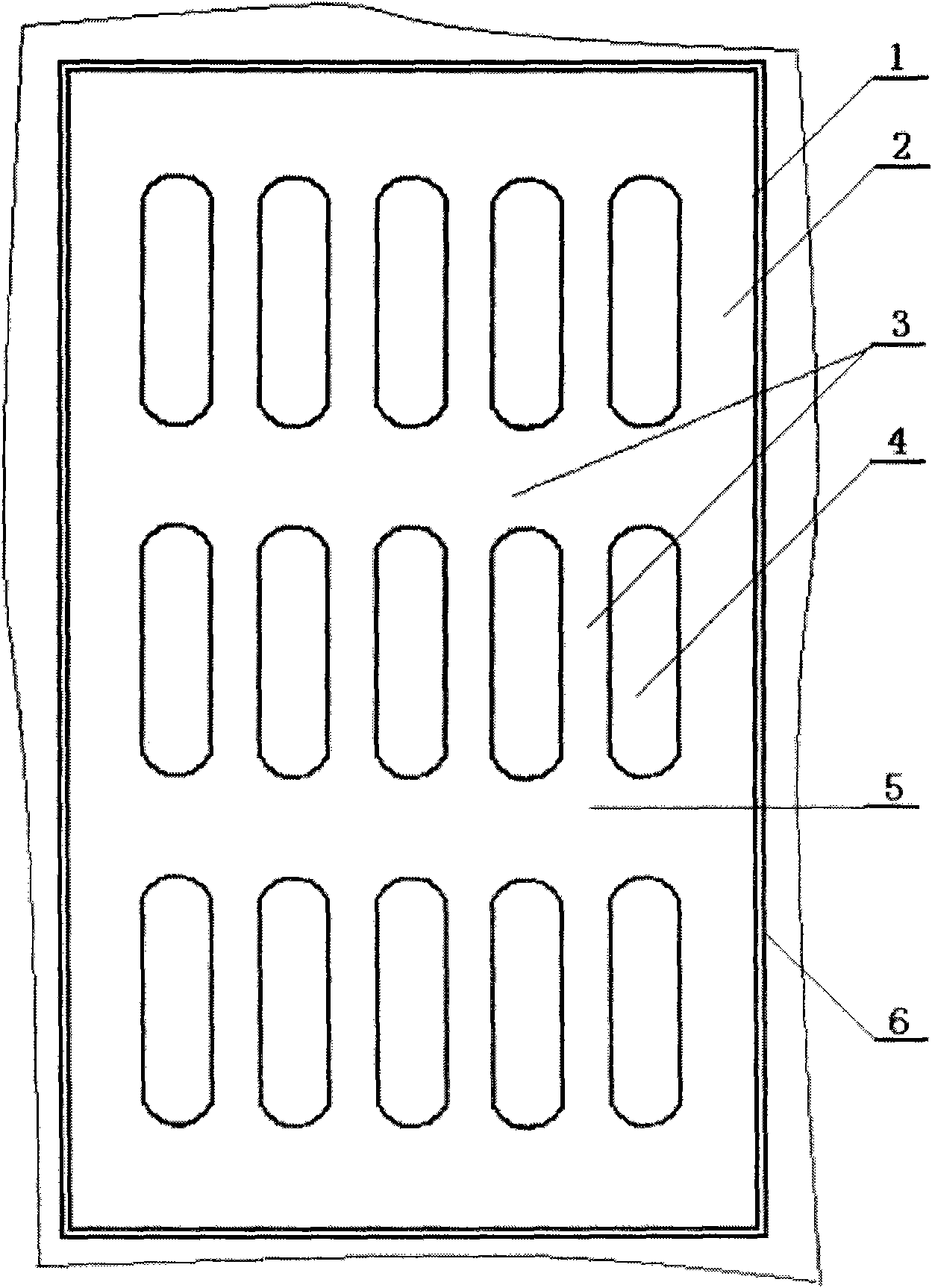

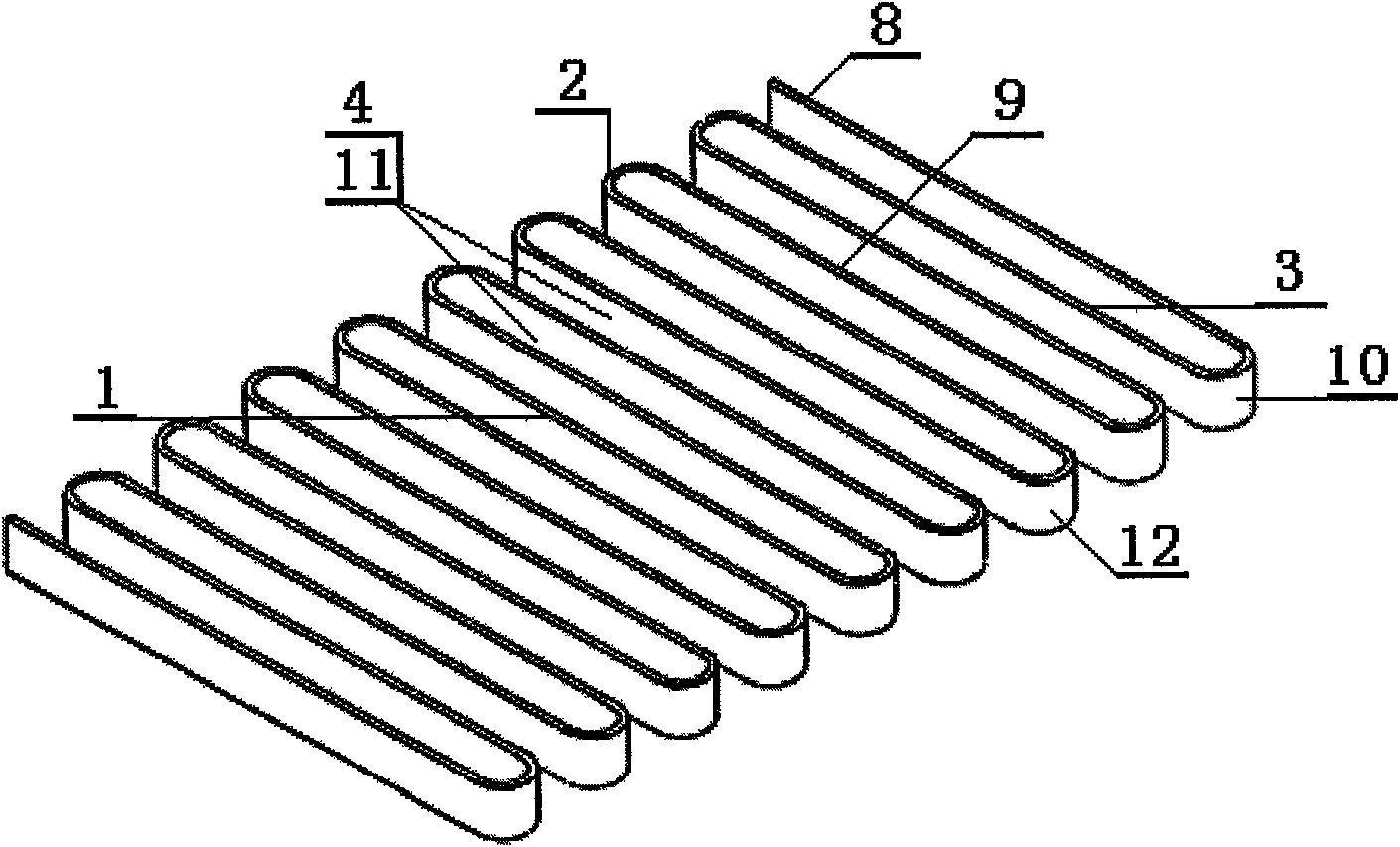

[0020] exist figure 2 Among them, the main body of the safety grating without continuous frame of the present invention is in the shape of a flat block, including the middle working surface 5 and the surrounding frame 2 composed of grid bars 3 and grid holes 4, and is characterized in that the middle The working surface 5 is "coil type", which is composed of a long straight strip 9 formed by continuous reverse bending of a strip flat plate 8 and a bending part 10 located between the ends of the long straight strip 9. The surrounding frame The side 2 is discontinuous, wherein: the grid bar 3 is served by the longer straight bar 9; the grid hole 4 is served by the gap 11 between the longer straight bars 9; The thickness of the flat block grid plate 1 is consistent with the width of the strip-shaped flat plate 8;

Embodiment 2

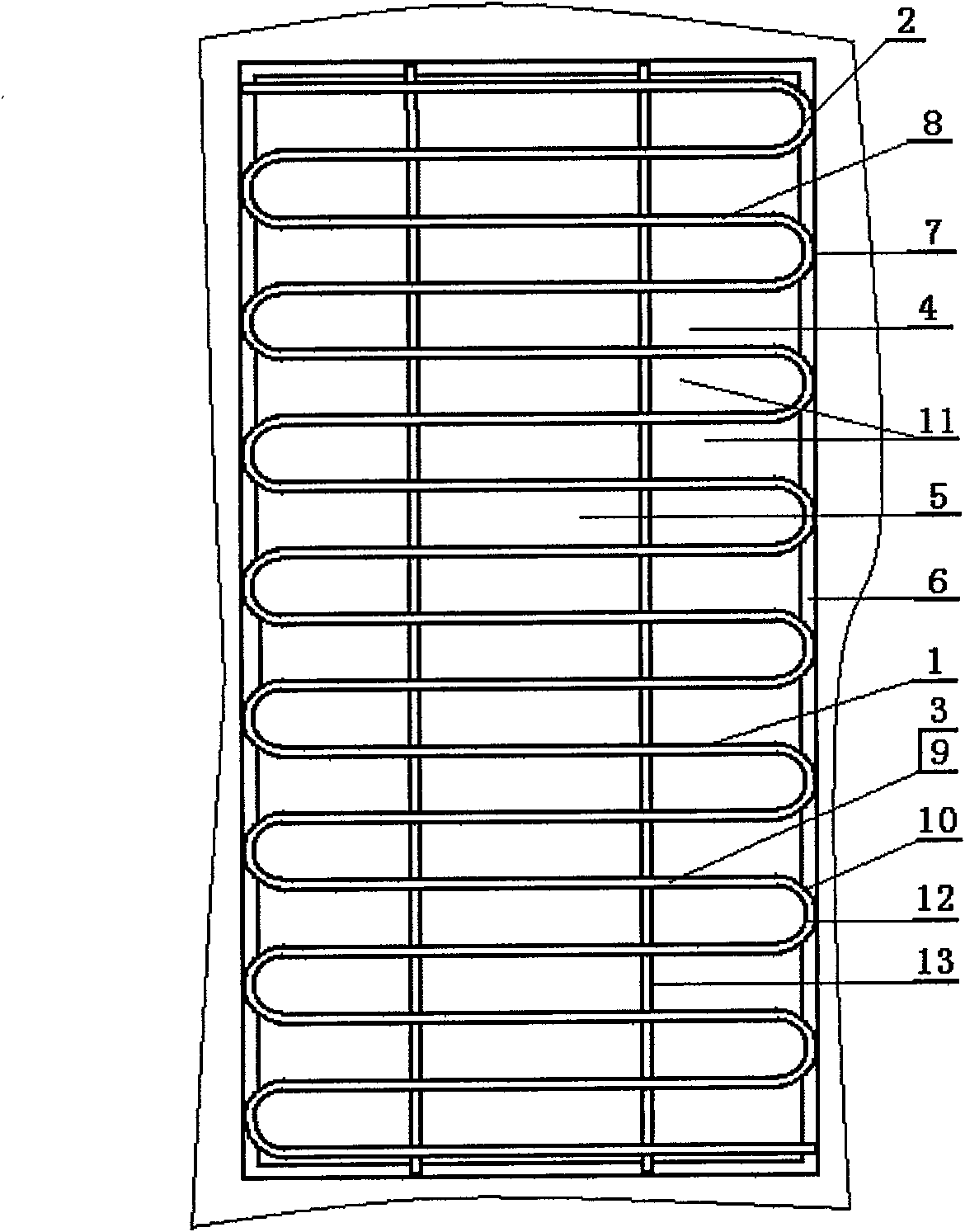

[0021] Embodiment 2 Enhanced

[0022] exist image 3 Among them, the main body of the safety grating without continuous frame of the present invention is in the shape of a flat block, including the middle working surface 5 and the surrounding frame 2 composed of grid bars 3 and grid holes 4, and is characterized in that the middle The working surface 5 is "coil type", which is composed of a long straight strip 9 formed by continuous reverse bending of a strip flat plate 8 and a bending part 10 located between the ends of the long straight strip 9. The surrounding frame The side 2 is discontinuous, wherein: the grid bar 3 is served by the longer straight bar 9; the grid hole 4 is served by the gap 11 between the longer straight bars 9; The thickness of the flat block grid plate 1 is consistent with the width of the strip flat plate 8; The back is also provided with longitudinal reinforcing ribs 13 .

Embodiment 3

[0023] Embodiment 3 sharp angle bending type

[0024] exist Figure 4 Among them, the main body of the safety grating without continuous frame of the present invention is in the shape of a flat block, including the middle working surface 5 and the surrounding frame 2 composed of grid bars 3 and grid holes 4, and is characterized in that the middle The working surface 5 is "coil type", which is composed of a long straight strip 9 formed by continuous reverse bending of a strip flat plate 8 and a bending part 10 located between the ends of the long straight strip 9. The surrounding frame The side 2 is discontinuous, wherein: the grid bar 3 is served by the longer straight bar 9; the grid hole 4 is served by the gap 11 between the longer straight bars 9; The thickness of the flat block grid plate 1 is consistent with the width of the strip flat plate 8; Also be provided with longitudinal stiffener 13 on the back side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com