A functional steel bridge deck pavement system for melting snow and ice

A technology for bridge deck pavement and steel deck, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems such as the difficulty of melting snow and ice on steel bridge decks, and achieve high interlayer shear strength, convenient construction, and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

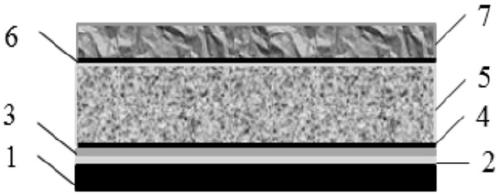

[0041] The steel bridge deck pavement system of the present invention paves an antirust layer 2, a waterproof layer 3, a first coupling layer 4, an elastic concrete layer 5, and a second coupling layer 6 on the steel bridge deck 1 sequentially from bottom to top , snow-melting and ice-melting functional layer 7.

[0042] The anti-rust layer 2 has a thickness of 0.1 mm and is made of zinc-rich epoxy resin, coated in two layers.

[0043] The thickness of the waterproof layer 3 is 2 mm, and the material is epoxy resin waterproof coating.

[0044] The thickness of the first coupling layer 4 and the second coupling layer 6 is 40 μm, and the material is a silane coupling agent.

[0045] The elastic concrete layer 5 has a thickness of 40 mm and is composed of three components A, B, and C. The material formula per cubic meter is: 400 kg of component A, 75 kg of component B, and 25 kg of component C;

[0046] The formula of component A in the elastic concrete layer 5 is as follows: 2...

Embodiment 2

[0060] The steel bridge deck pavement system of the present invention paves an antirust layer 2, a waterproof layer 3, a first coupling layer 4, an elastic concrete layer 5, and a second coupling layer 6 on the steel bridge deck 1 sequentially from bottom to top , snow-melting and ice-melting functional layer 7.

[0061] The anti-rust layer 2 has a thickness of 0.15mm, and the material is zinc-rich epoxy resin, which is coated with 3 layers.

[0062] The thickness of the waterproof layer 3 is 2.5mm, and the material is epoxy resin waterproof coating.

[0063] The thickness of the first coupling layer 4 and the second coupling layer 6 is 40 μm, and the material is a silane coupling agent.

[0064] The elastic concrete layer 5 has a thickness of 45 mm and is composed of three components A, B, and C. The material formula per cubic meter is: 500 kg for A component, 75 kg for B component, and 25 kg for C component;

[0065] The formula of component A in the elastic concrete layer...

Embodiment 3

[0079] The steel bridge deck pavement system of the present invention paves an antirust layer 2, a waterproof layer 3, a first coupling layer 4, an elastic concrete layer 5, and a second coupling layer 6 on the steel bridge deck 1 sequentially from bottom to top , snow-melting and ice-melting functional layer 7.

[0080] The anti-rust layer 2 has a thickness of 0.2mm and is made of zinc-rich epoxy resin, and is coated with 3 layers.

[0081] The thickness of the waterproof layer 3 is 2 mm, and the material is epoxy resin waterproof coating.

[0082] The thickness of the first coupling layer 4 and the second coupling layer 6 is 40 μm, and the material is a silane coupling agent.

[0083] The elastic concrete layer 5 has a thickness of 50 mm and is composed of three components A, B, and C. The material formula per cubic meter is: 500 kg of component A, 75 kg of component B, and 25 kg of component C;

[0084] The formula of component A in the elastic concrete layer 5 is: 3 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com