Impeller structure of centrifugal lampblack filter

A technology for oil fume filtration and centrifugal impeller, which is applied to the removal of oil fume, components of a pumping device for elastic fluids, heating methods, etc., can solve the problems such as inability to be popularized and applied in batches, complex structure and manufacturing process, and reduced oil fume inhalation capacity. , to achieve the effect of facilitating mass popularization and application, simple and reasonable manufacturing process, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

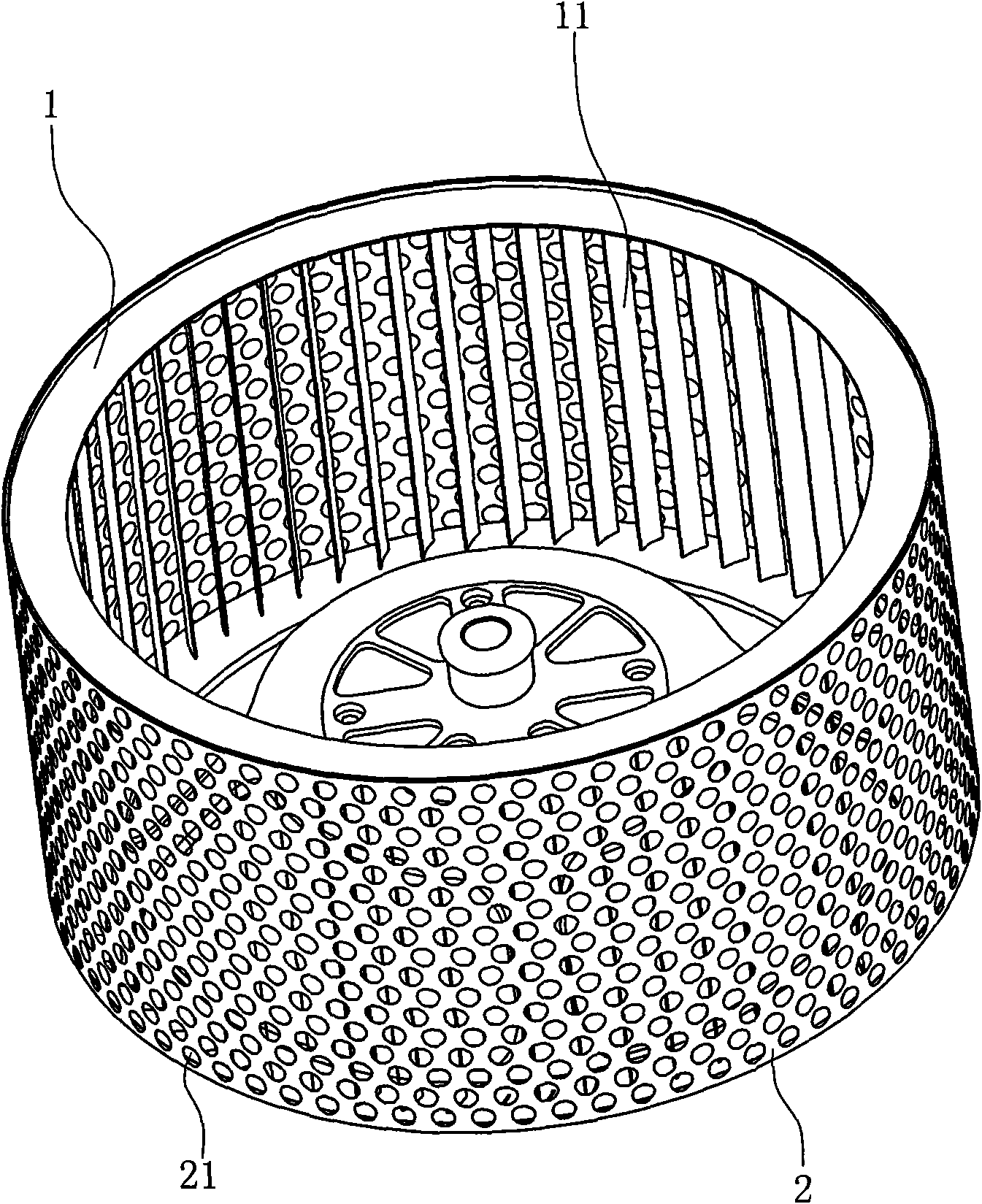

[0017] Such as figure 1 Shown is the first embodiment of the present invention.

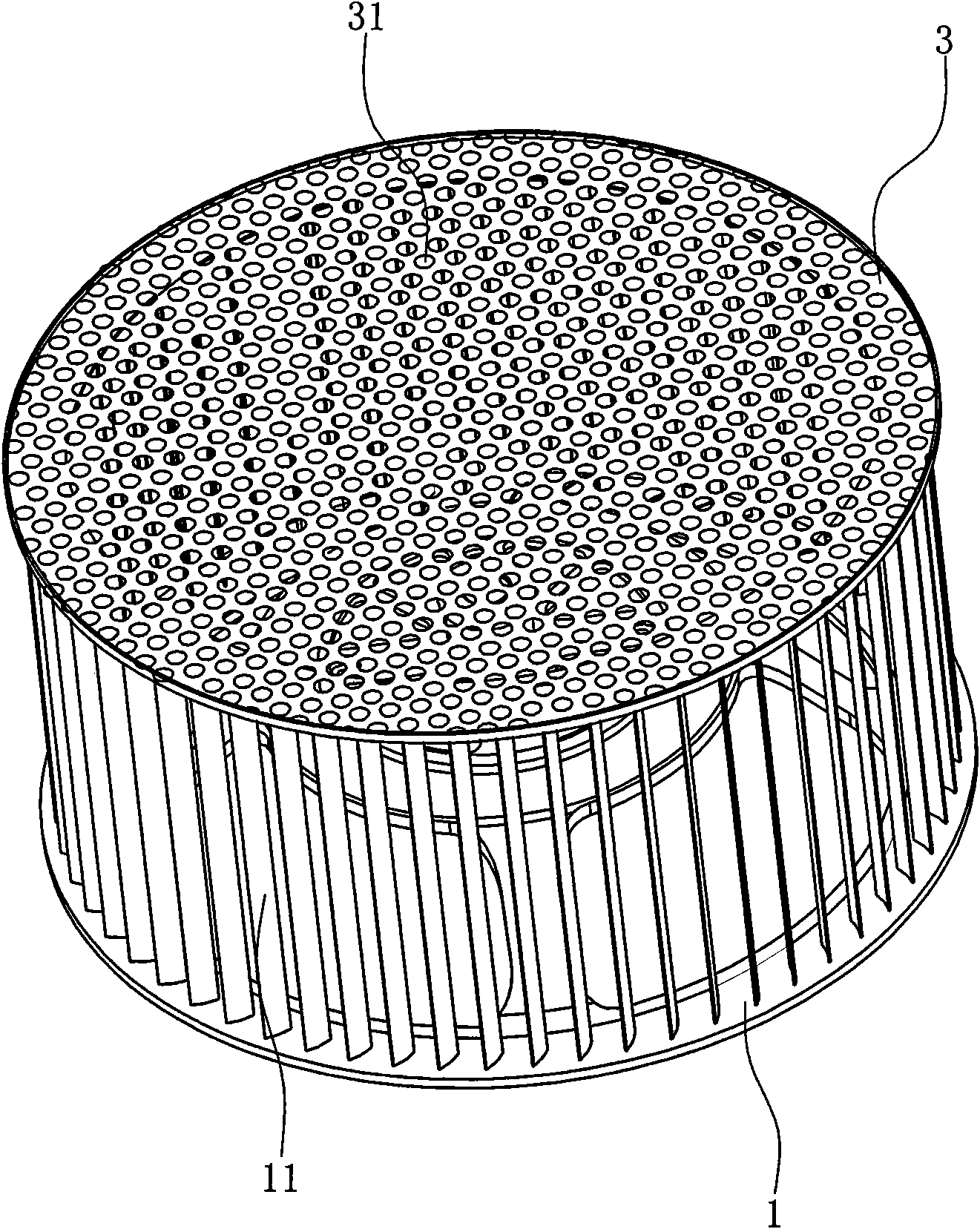

[0018] An impeller structure of a centrifugal oil fume filter device, comprising a multi-blade centrifugal impeller body 1 and a mesh-shaped side filter plate 2, the thickness of the side filter plate 2 is 0.2-1 mm, and the side filter plate 2 is a perforated mesh Densely arranged mesh holes 21 are stamped on it, and the size of the mesh holes 21 on the side filter plate 2 is 1-8 mm.

[0019] The side filter plate 2 is outpacked and fixed on the outer circumferential surface of the multi-blade centrifugal impeller body 1 so as to be able to rotate at a high speed with the multi-blade centrifugal impeller body 1 , that is, the outside of the blades 11 in the multi-blade centrifugal impeller body 1 .

[0020] The overall shape of the side filter plate 2 in this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com