Formed article for vehicle body structural member

A technology for formed products and car bodies, which is applied to vehicle components, superstructure sub-assemblies, superstructures, etc., can solve the problems of reduced dimensional accuracy and difficulty in obtaining shapes, and achieve the effect of reducing residual stress and improving dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

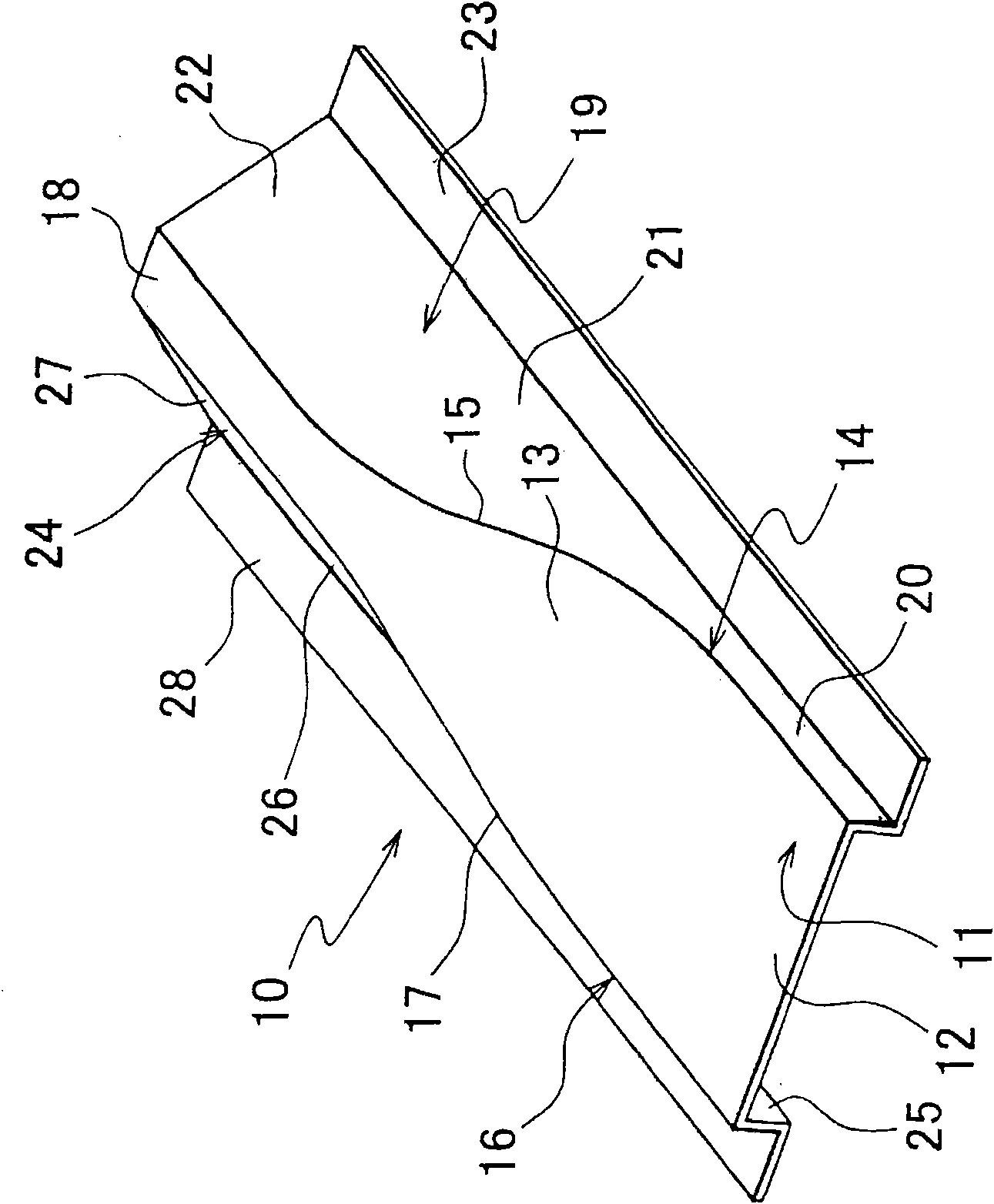

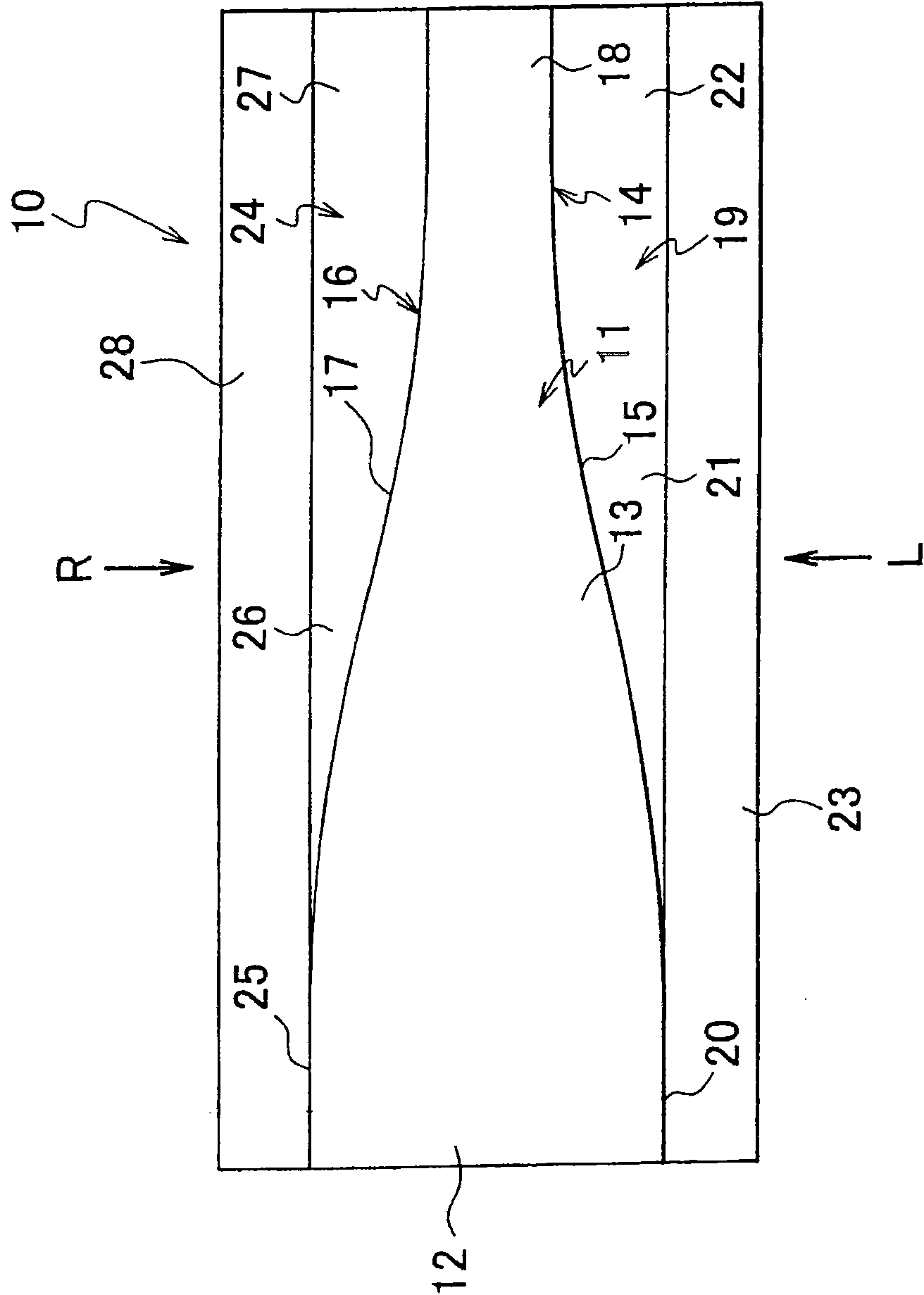

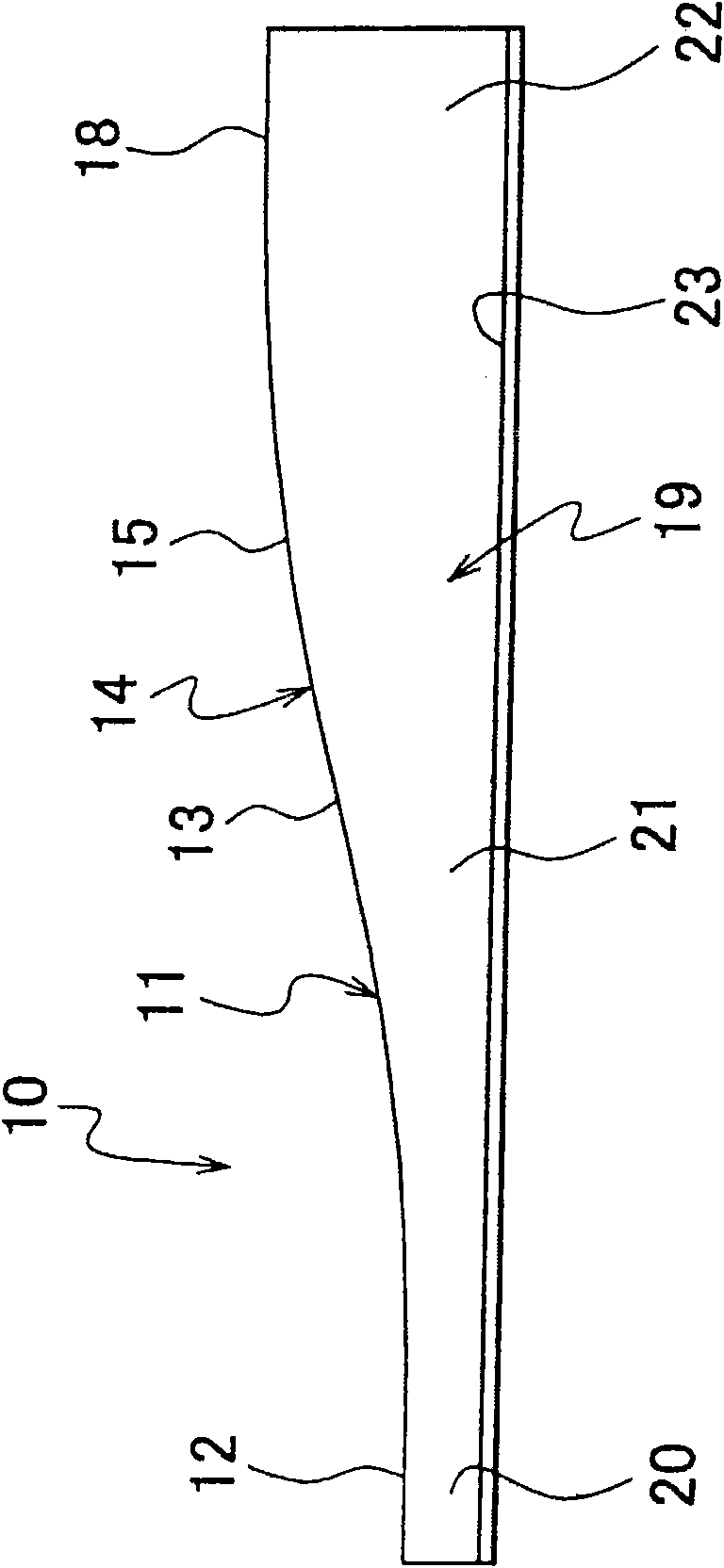

[0037] FIG. 1 shows the structure of a molded article 10 for a vehicle body member according to a first embodiment of the present invention in a perspective view. FIG. 2 shows a plan view of a molded product 10 for a body member. FIG. 3 shows a side view of the molded article 10 for a vehicle body member when viewed from the arrow L side in FIG. 2 . FIG. 4 shows a side view of the molded product 10 for a vehicle body member when viewed from the arrow R side in FIG. 2 , that is, from the opposite side compared to the case of FIG. 3 .

[0038] As shown in these figures, the molded product 10 for a vehicle body member includes a top wall portion 11 that can be regarded as a gradation portion forming wall. The top wall portion 11 includes a lower flat portion 12 in a flat shape. A top wall transition portion 13 , which may be regarded as a first transition portion, continuously extends from one end of the lower flat portion 12 relative to the longitudinal direction of the top wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com