Methods for matching and debugging signals in tire pressure monitoring system

A technology of tire pressure monitoring and signal matching, which is applied in the field of signal matching, can solve the problems of being unable to overcome the same last three digits, mistakenly learning the sensor transmitter, and not suitable for tires, etc. It is easy to popularize, the device structure is simple, and it is easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

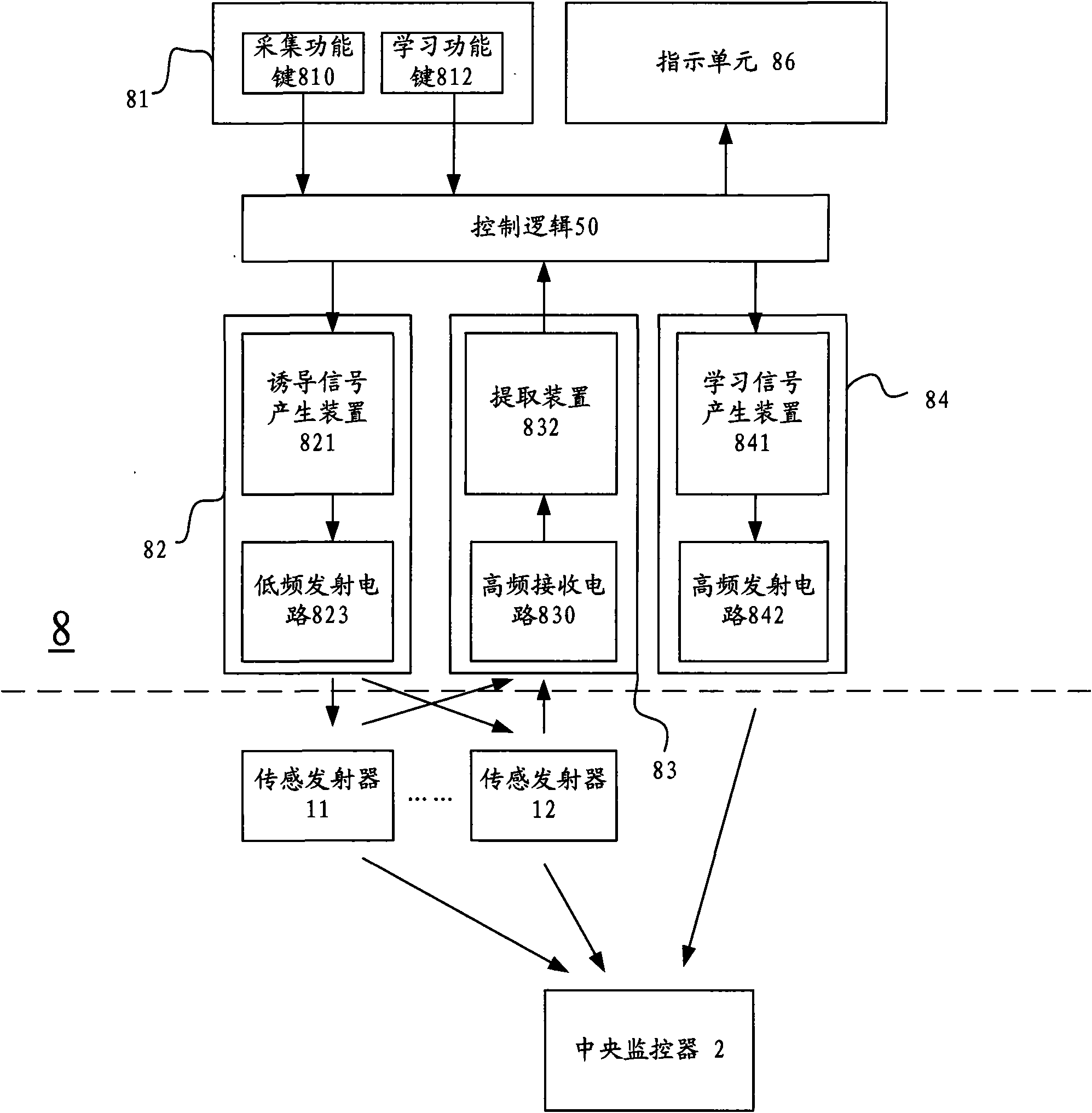

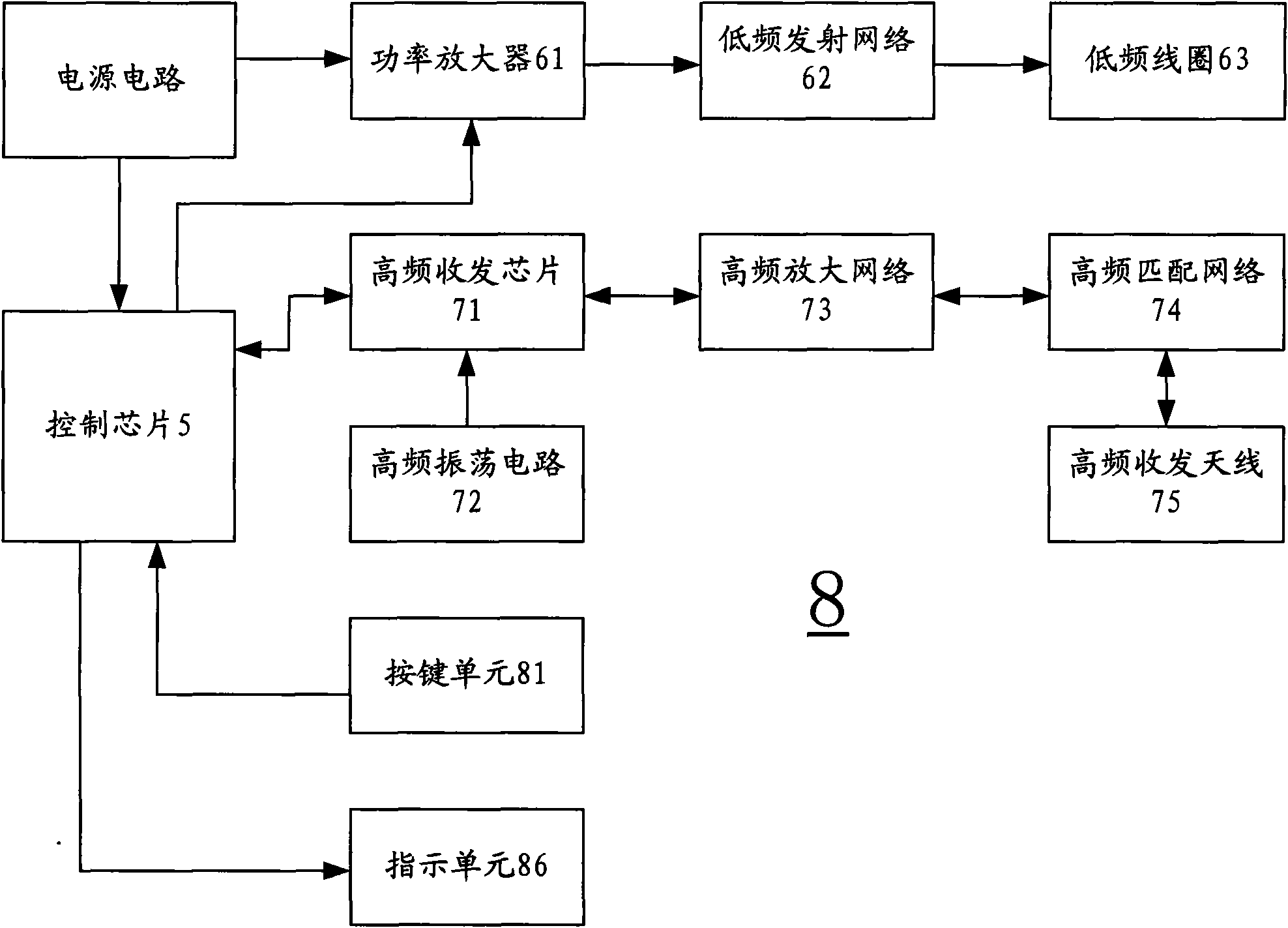

[0057] see figure 1 , the known tire pressure monitoring system includes a plurality of sensing transmitters 11, 12 and a central monitor 2, and the sensing transmitters 11, 12 have a low-frequency circuit (not shown) and a high-frequency circuit (not shown) ), the low-frequency circuit is mainly used to receive the signal sent when the pressure and / or temperature are dangerous, such as exceeding a certain rated value, and the signal will be disguised in one of the following embodiments of the present invention, the high-frequency circuit is used to send The central monitor 2 transmits a real-time signal, and the central monitor 2 gives an alarm after receiving the real-time signal through its own high-frequency circuit (not shown).

[0058] The present invention is based on this principle, transmits the low-frequency circuit of sensing transmitter 11, 12 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com