Method for controlling band steel sag for pickling bath

A kind of control method, technology of pickling tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

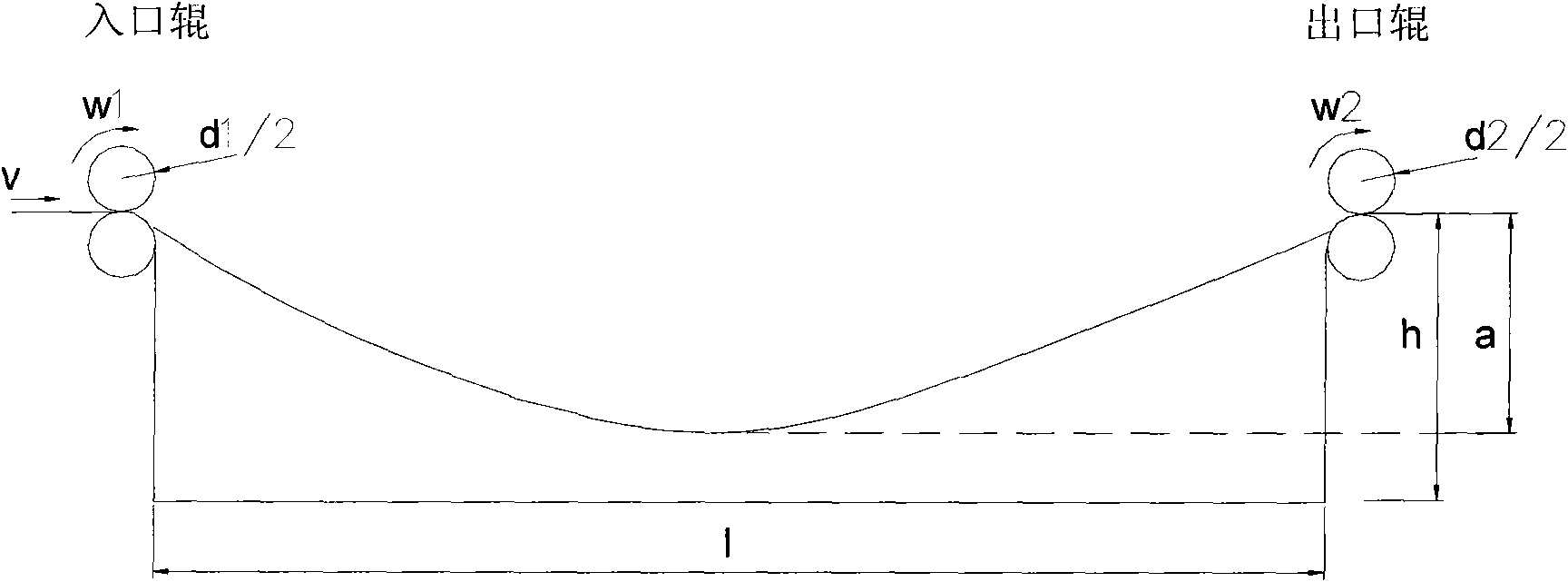

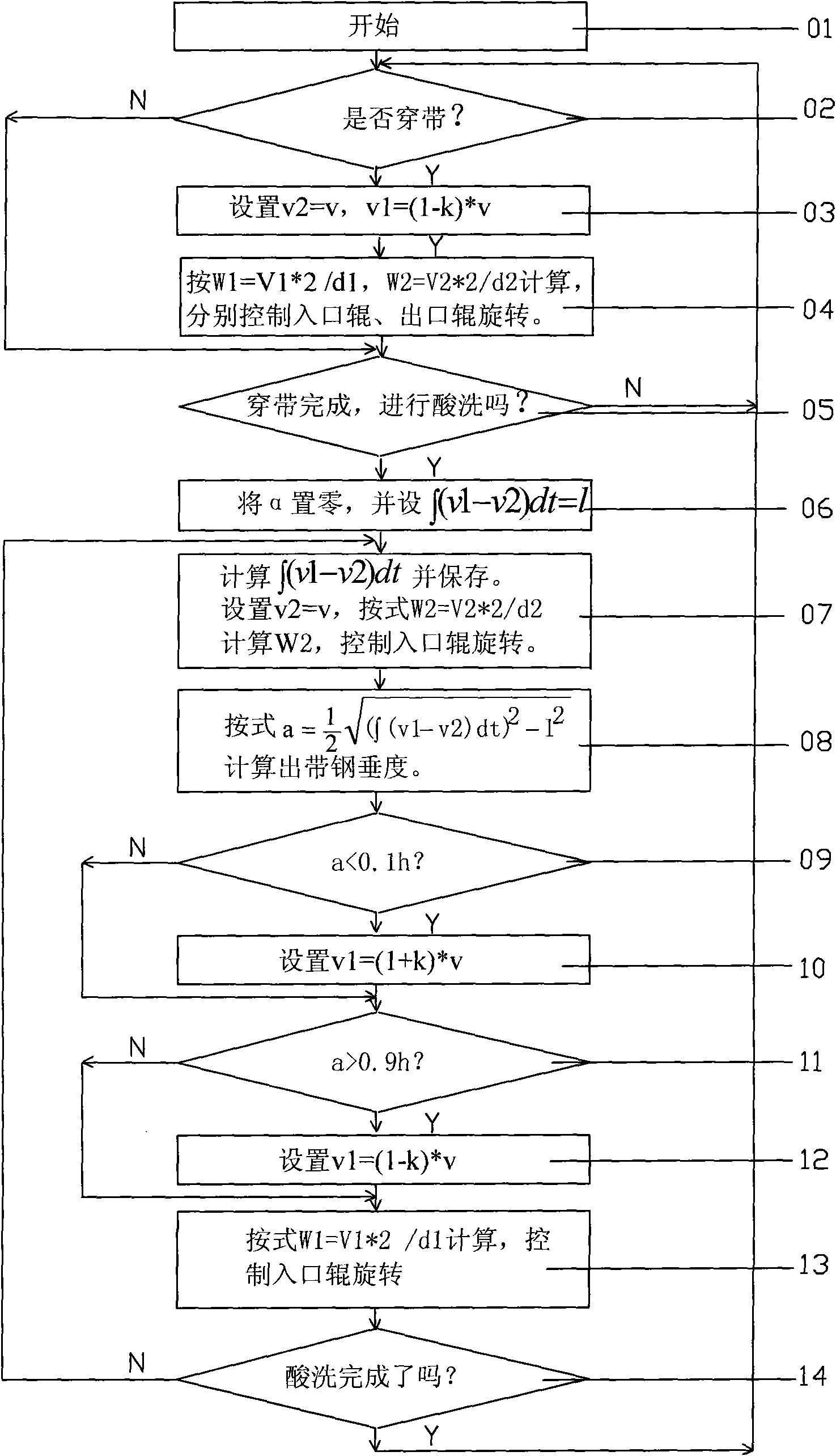

[0011] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

[0012] The basic idea of the present invention is to explore a method for improving strip pickling efficiency under the premise of ensuring output and not increasing production cost.

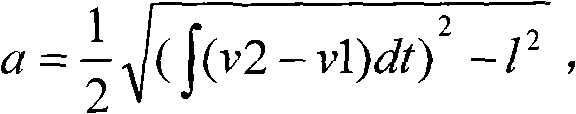

[0013] The principle of the present invention is: according to the actual size of the acid tank, the calculation formula for the sag of the acid tank is obtained, the speed of the inlet roll of the acid tank is adjusted according to a certain rule, and the speed of the exit roll is maintained at the strip line speed, so that the sag is within a certain range The change is not to control the sag to be constant, but to control the sag to change up and down within the allowab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com