Array type horizontal shaft wind-power blade

A wind power blade and horizontal shaft technology, applied in the field of split horizontal shaft wind power blades, can solve the problems of heavy blade weight, difficult processing, complex structure, etc., and achieve the effects of good aerodynamic performance, reduced blade weight, and simple internal mechanism of the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions provided by the present invention are further described below in conjunction with the examples.

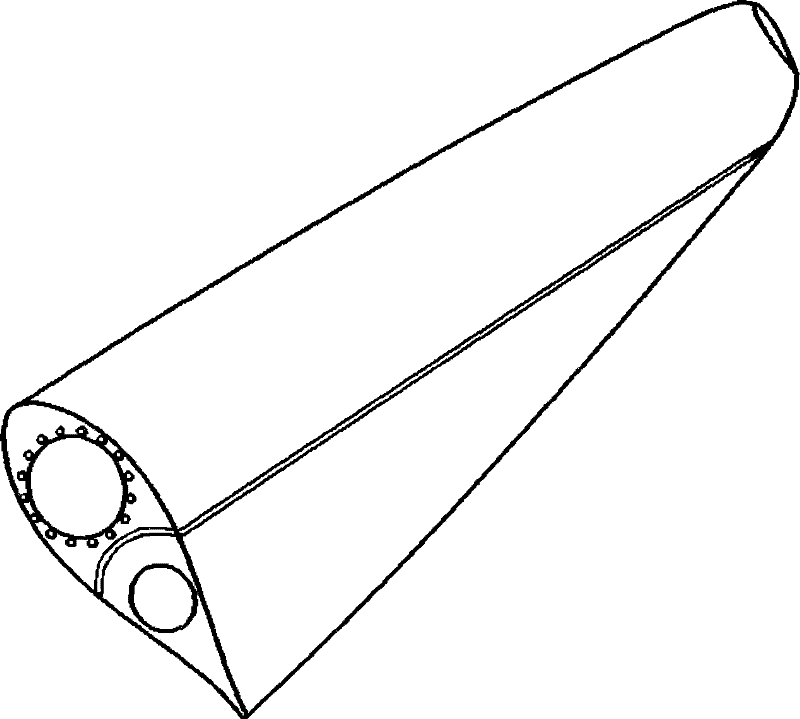

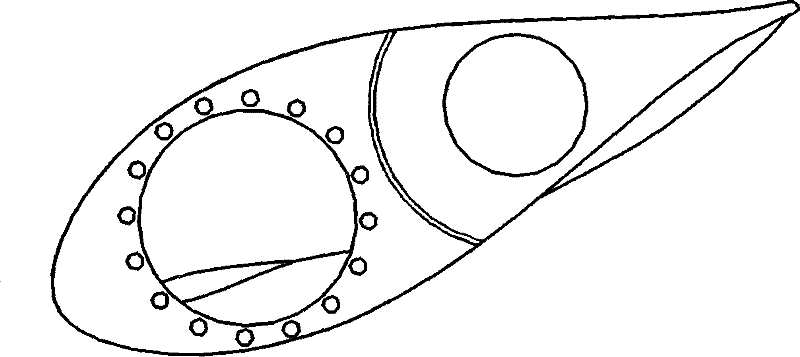

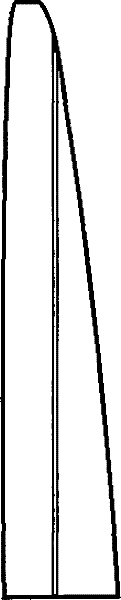

[0028] like figure 1 , 2 As shown in , 3, the transverse section of the horizontal axis wind power blade with split blades perpendicular to the span direction is a typical airfoil of a wind power machine. The size ratio can be properly distributed, for example, if the area of the adjustable part is increased, the adjustment effect of the blade can be increased, but the adjustment power will be increased accordingly. The present invention is applicable to the design of blades of horizontal-axis wind turbines of various sizes and power ranges. The contact surface of the two parts along the spanwise split crack is a matching arc surface, which is convenient for adjustment and greatly reduces the need for adjustment. power used, such as Figure 4 shown.

[0029] The root of the front part is provided with a fixed flange and is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com