Tenon-type turbine blade with five pressure sensing holes on elementary-stage front edge

A turbine blade and element-level technology, which is applied to blade support components, engine components, machines/engines, etc., can solve problems such as inability to accurately measure flow field parameters between stages, achieve light weight, improve measurement resolution, reduce The effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

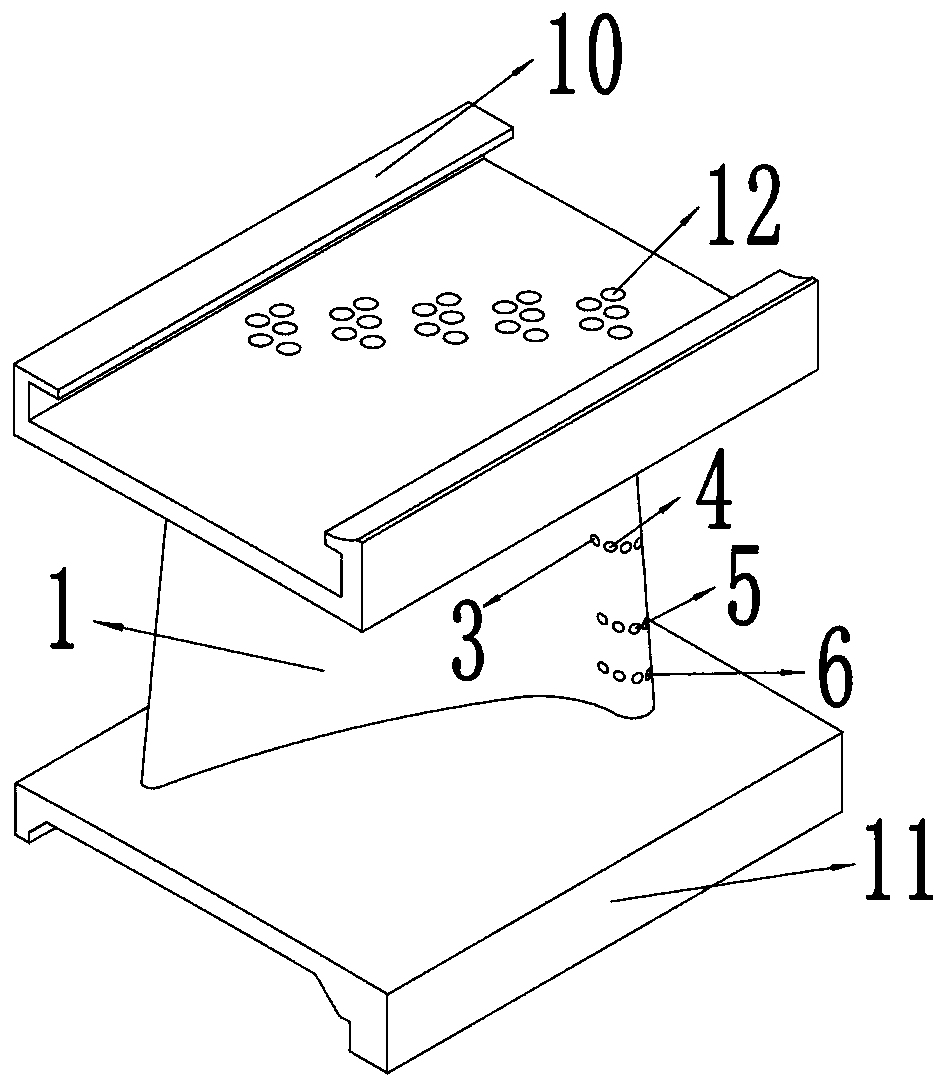

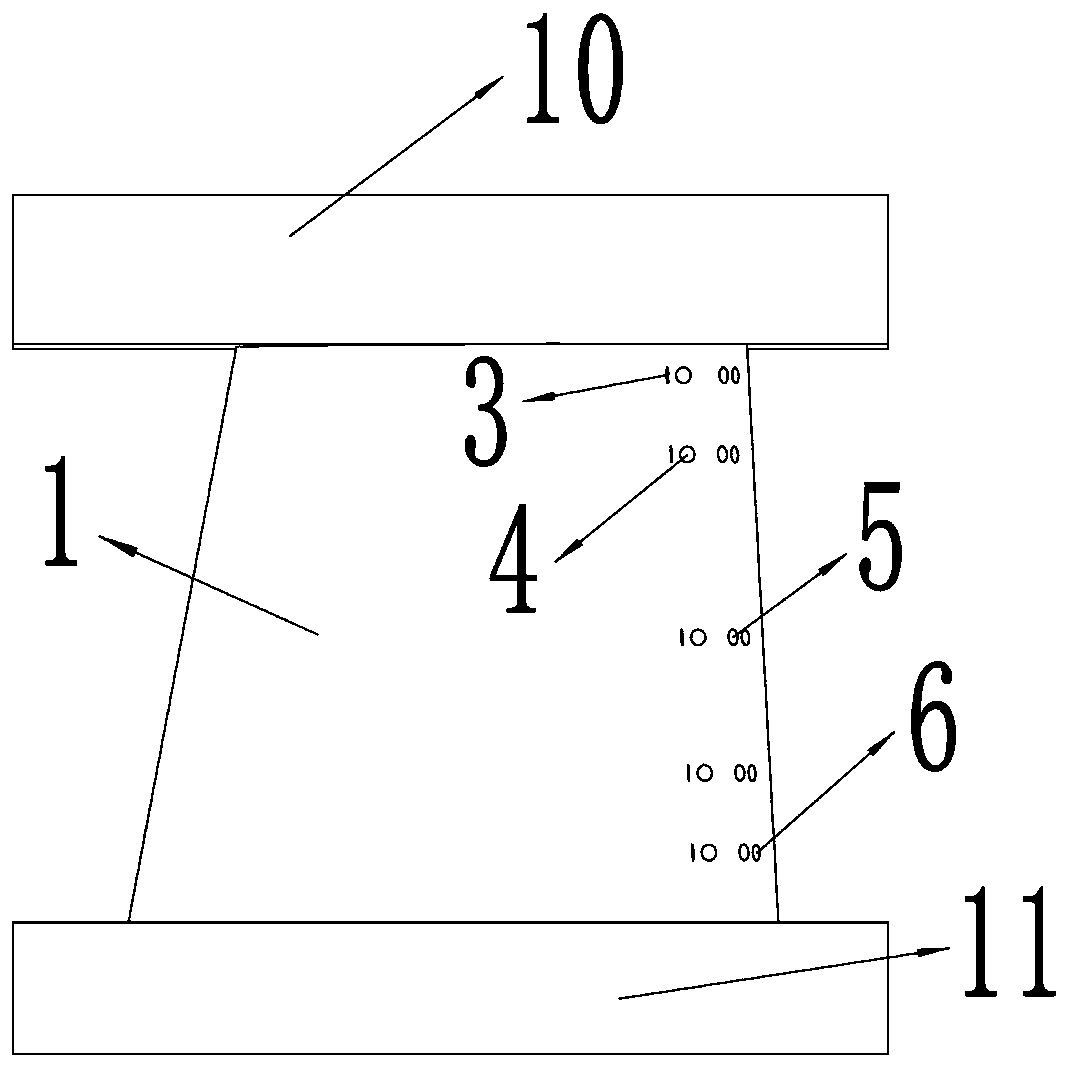

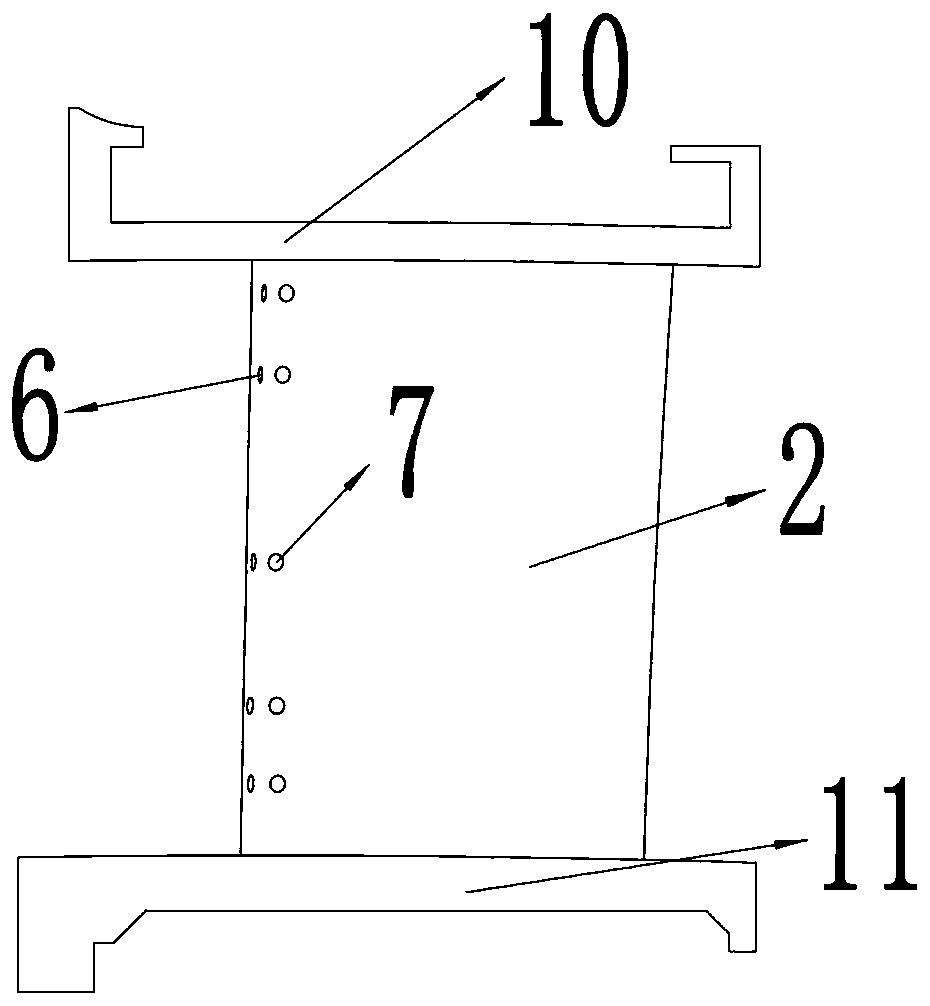

[0038] Such as figure 1 , figure 2 and image 3 As shown, a tenon-type turbine blade with five pressure-sensing holes on the leading edge is introduced in this embodiment; the blade includes a blade pressure surface (1), a blade suction surface (2), and a pressure sensing hole behind the pressure surface (3 ), pressure sensing hole (4) on the pressure front, pressure sensing hole on the leading edge point (5), pressure sensing hole (6) on the suction front, pressure sensing hole (7) behind the suction side, pressure channel (8), low loss bend Pipe (9), blade top tenon (10), blade root tenon (11), pressure introduction pipe interface (12). Among them, the blade has five rows of pressure sensing holes distributed along the blade height direction, and each row includes the leading edge point pressure sensing holes (5) located at the leading edge point of the primitive level, and the pressure sensing holes located on the pressure surface (1) of the blade behind the pressure su...

Embodiment 2

[0044] Such as Figure 9 , Figure 10 and Figure 11 As shown, a tenon-type turbine blade with five pressure-sensing holes on the leading edge is introduced in this embodiment; the blade includes a blade pressure surface (1), a blade suction surface (2), and a pressure sensing hole behind the pressure surface (3 ), pressure sensing hole (4) on the pressure front, pressure sensing hole on the leading edge point (5), pressure sensing hole (6) on the suction front, pressure sensing hole (7) behind the suction side, pressure channel (8), low loss bend Pipe (9), blade top tenon (10), blade root tenon (11), pressure introduction pipe interface (12). Among them, the blade has three rows of pressure sensing holes distributed along the blade height direction, and each row includes a leading edge point pressure sensing hole (5) located at the leading edge point, and a rear pressure sensing hole (3) located on the pressure surface (1) of the blade. ) and the pressure sensing hole (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com