Hydraulic round platform gear pump

A gear pump and round table technology, applied in the field of hydraulic gear pumps, can solve the problems of loose meshing between the driving gear and the driven gear, the working noise of the hydraulic gear pump becomes larger, and the power fails to meet the design requirements, so as to reduce the clearance, The effect of meeting power requirements and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

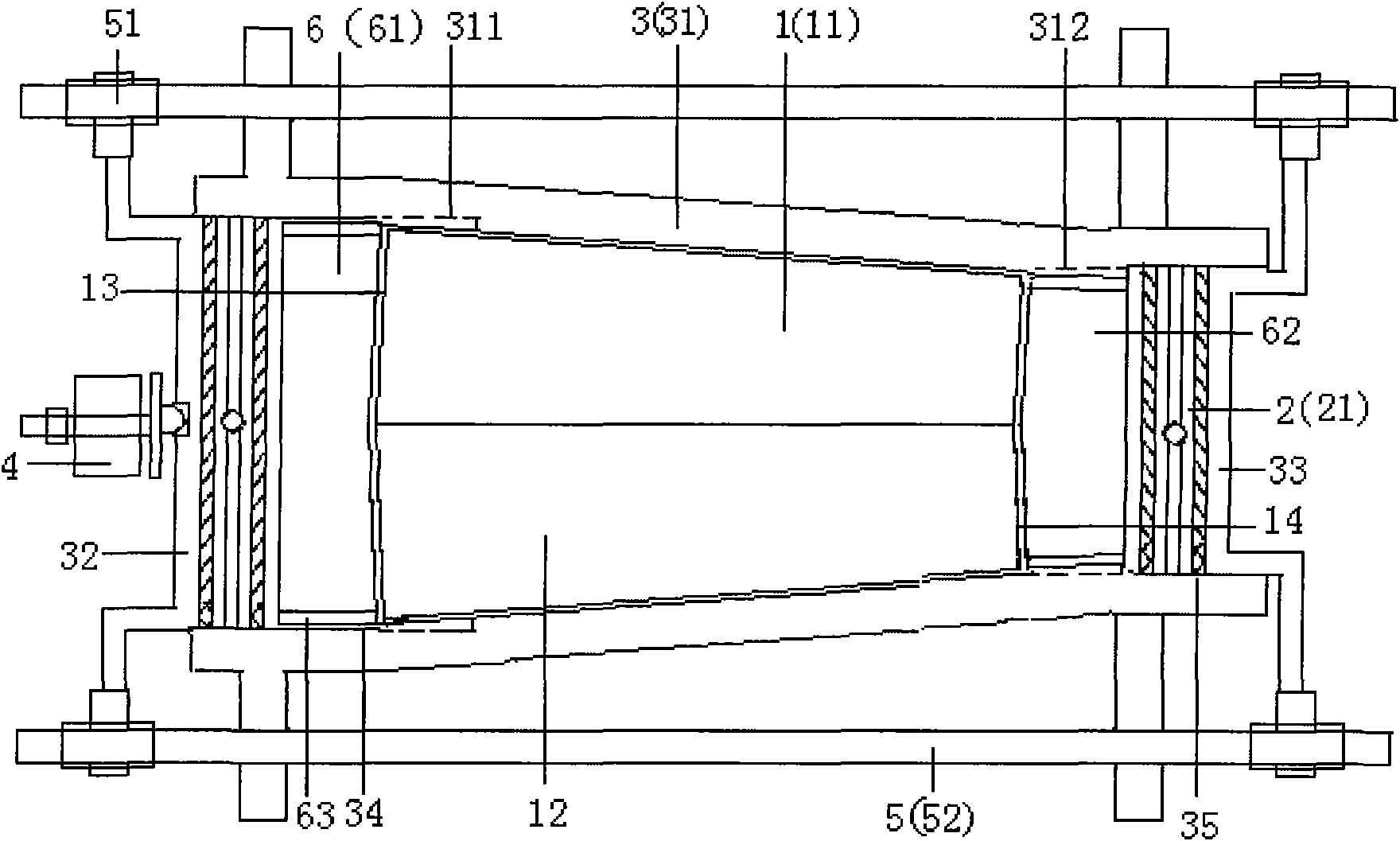

[0017] Such as figure 1 as shown,

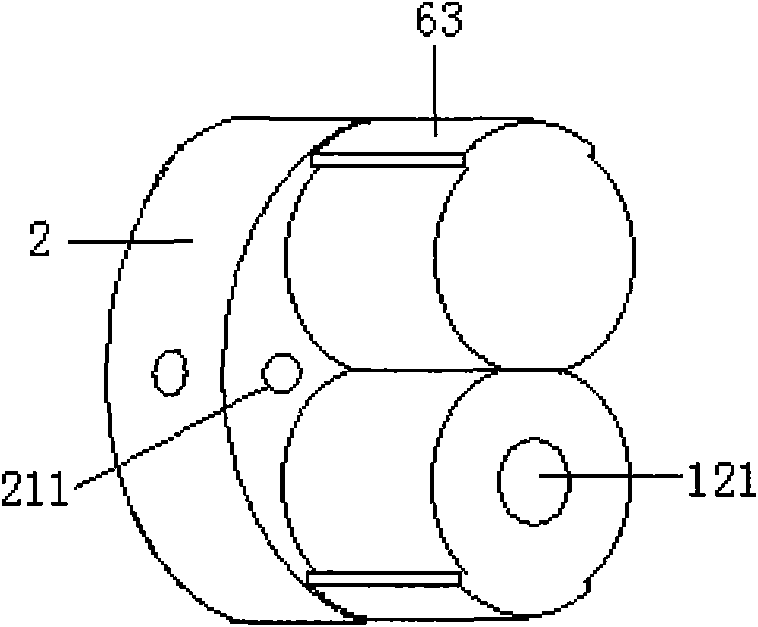

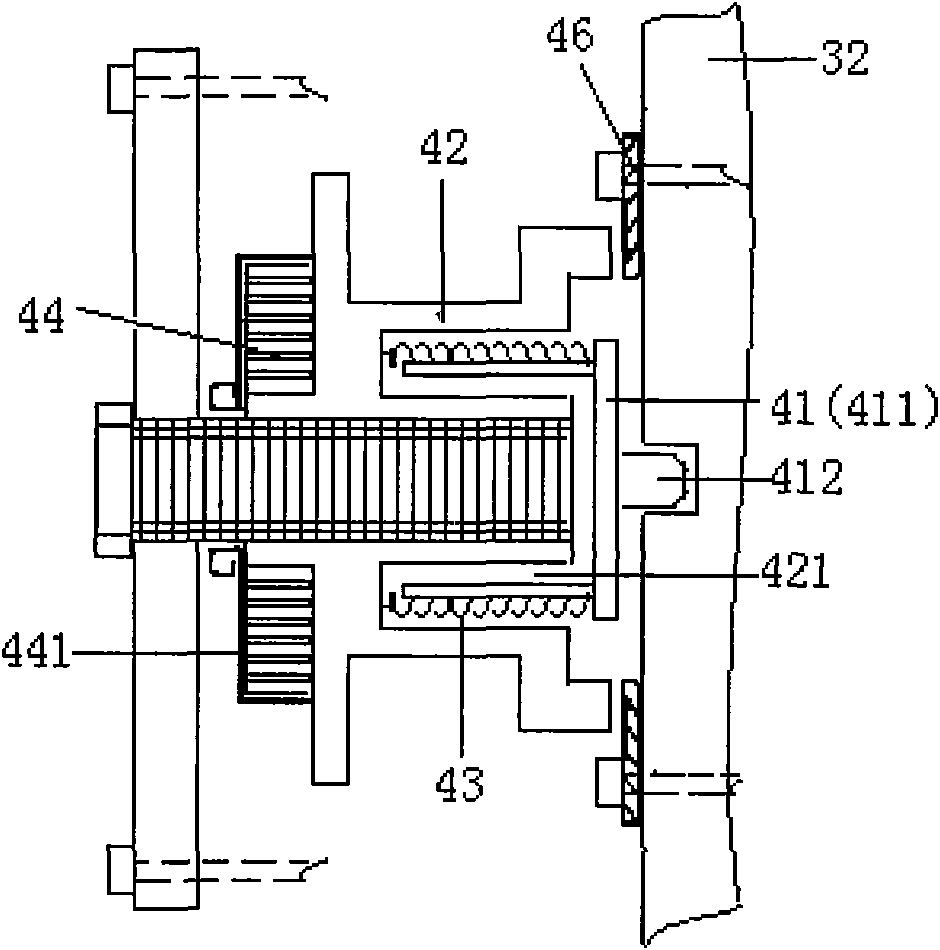

[0018] The gear 1 of the present invention and the return device 2 of the oil circuit are all arranged in the inner casing 3 with end covers at both ends, the driving gear 11 and the driven gear 12 are circular table gears with the same size, and the barrel of the casing The body 31 is consistent with the taper of the round platform gear, and the outer casing end cover 32 of the large round platform 13 ends of the round platform is provided with an end cover propulsion device 4, and the end cover 32 and the casing end cover 33 of the small round platform 14 ends of the round platform are all provided with There is a sliding rod 5, and the sliding rod end 51 is located in the long sliding groove 52 provided between the two end covers. In addition, a machine cover (not shown) is provided outside the two end covers.

[0019] another example figure 1 as shown,

[0020] Ejection cylinders 6 are provided between the two ends of the circular pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com