Transformer iron core structure with auxiliary iron yoke

A technology of transformers and iron yokes, which is used in the manufacture of inductors/transformers/magnets, transformers/inductor cores, electrical components, etc. Incomplete distribution, etc., to achieve reasonable leakage flux, eliminate local overheating, and enhance short-circuit resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

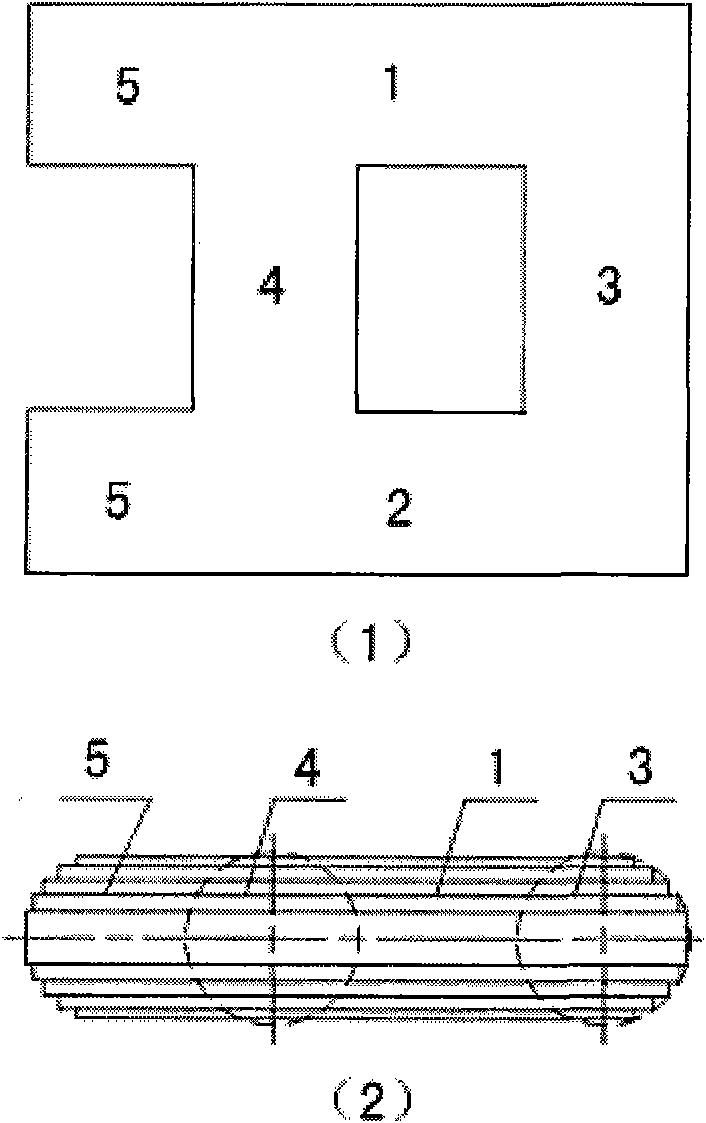

[0015] Such as figure 1 As shown, in the horizontal extension direction of the upper iron yoke 1 and the horizontal extension direction of the lower iron yoke 2 on the side of the core column 4 of the transformer core set winding of the single-phase two-column single-column structure, the auxiliary iron yoke 5 is added, and the upper and lower yokes are correspondingly extended The length of the iron core clamp increases the effective support of the transformer body.

Embodiment 2

[0017] Such as figure 2 As shown, for a transformer core with a single-phase two-column and two-core column structure with two-column windings operating independently, two-column windings in parallel or in series, the horizontal extension direction of the upper iron yoke 1 and the horizontal extension of the lower iron yoke 2 on the outside of the two core columns 4 In both directions, the auxiliary iron yoke 5 is added, and the length of the upper and lower iron core clips is correspondingly extended to increase the effective support of the transformer body.

Embodiment 3

[0019] Such as image 3 As shown, for a transformer core with a three-phase three-column structure, the auxiliary iron yoke 5 is added in the horizontal extension direction of the upper iron yoke 1 and the horizontal extension direction of the lower iron yoke 2 outside the two outer core columns 4, and the length of the iron core clamp is correspondingly extended , Increase the effective support of the transformer body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com