Fan and flow-guided structure thereof

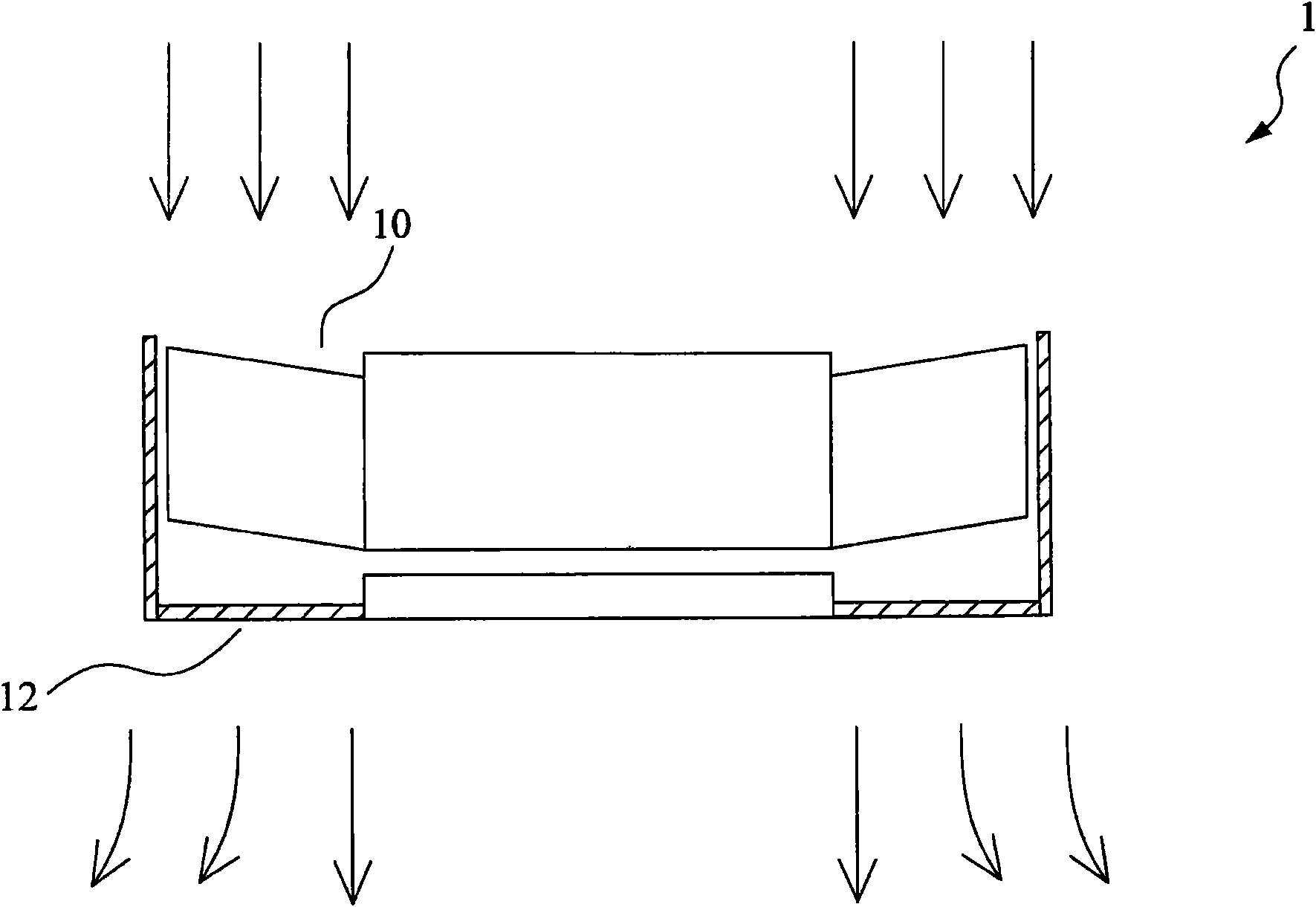

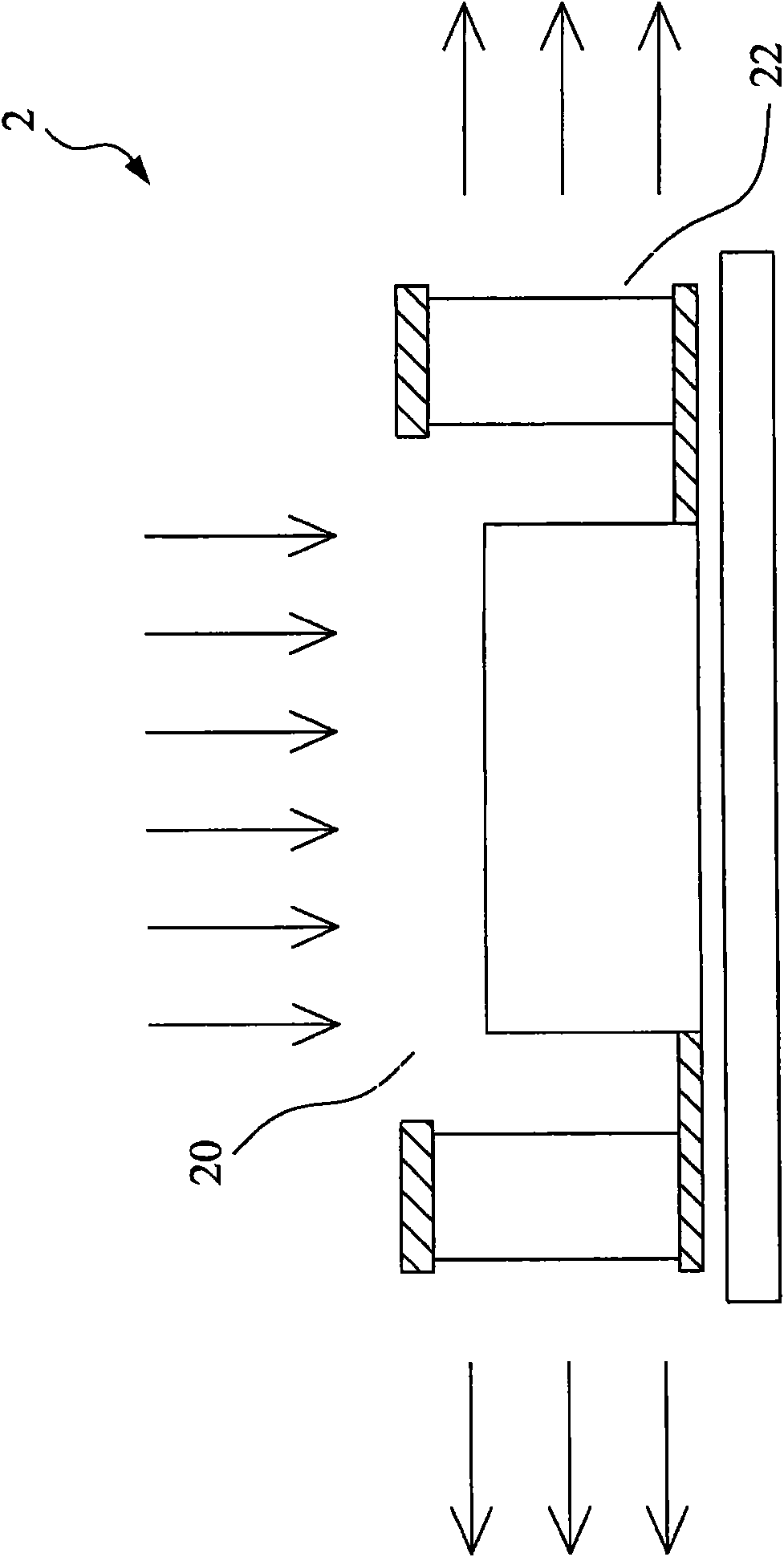

A fan and fan blade technology, applied in the field of fans that can change the air flow direction, can solve the problems of low efficiency, loud noise, and low air output, and achieve the effect of large air output, low noise, and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

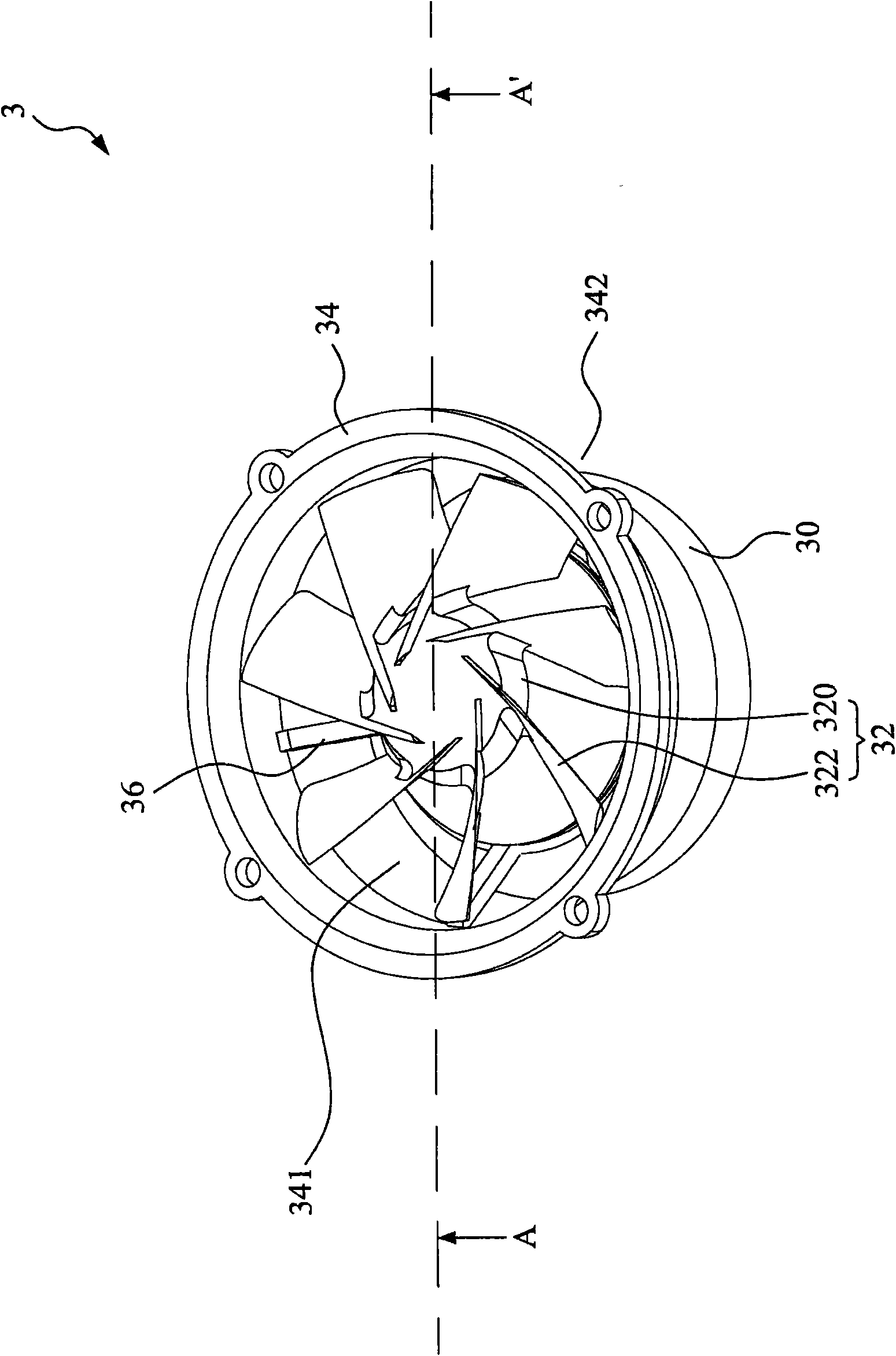

[0037] Please also refer to image 3 and Figure 4 as shown, image 3 is a perspective view of the first embodiment of the present invention, Figure 4 is along image 3 Sectional view of section line A-A' in the middle. As shown in the figure, the fan 3 of the present invention includes a flow guide structure 30 , an impeller 32 and a guide ring 34 .

[0038] The outer diameter of the flow guide structure 30 gradually expands from the top of the flow guide structure 30 to the bottom of the flow guide structure 30 , so that the outer ring surface of the flow guide structure 30 forms at least one curved surface. The impeller 32 is disposed above the flow guiding structure 30 , and the impeller 32 has a hub 320 and a plurality of fan blades 322 . The fan blade 322 is disposed on the outer ring surface of the hub 320 , and the hub 320 is provided with a motor (not shown in the figure), and the outer diameter of the hub 320 gradually expands from the top of the hub 320 to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com