Polyolefine water-proof tarpaulin and preparing method thereof

A manufacturing method and technology of waterproof cloth, applied in chemical instruments and methods, textiles, fabrics, etc., can solve the problems of non-recycling, decreased weather resistance, poor printing, etc., and achieve easy identification of digital surface printing and improved wear resistance. , digital surface printing clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

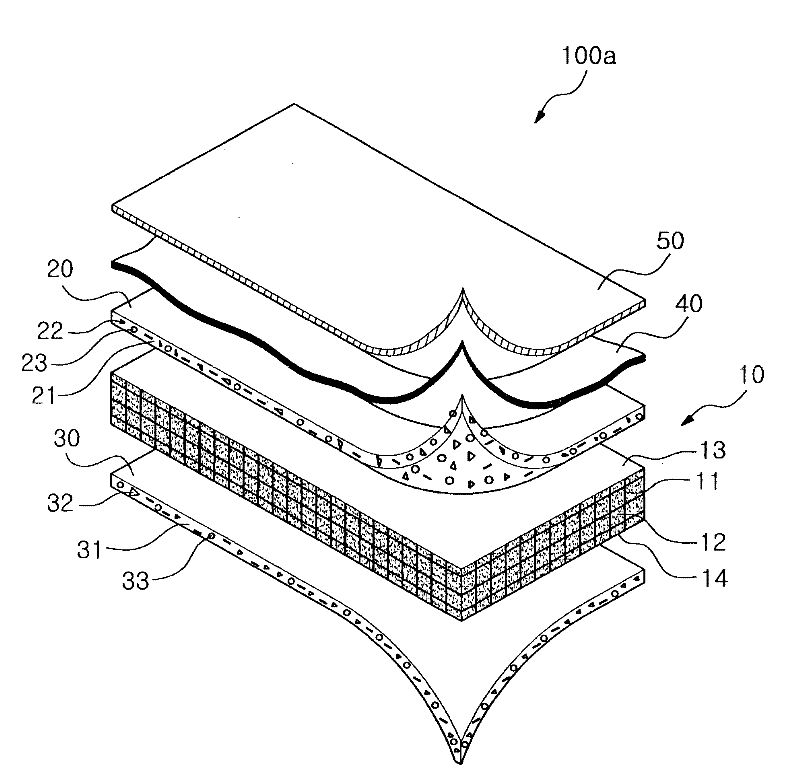

[0104] Embodiment 1 is made up of the upper and lower films, the adhesive layer and the surface treatment layer composed of the base material and the upper and lower film formations of the present invention. On the top of the surface treatment layer produced by the manufacturing method of the present invention, digital printing is directly carried out by a digital printing machine. tarpaulin on the printing side;

Embodiment 2

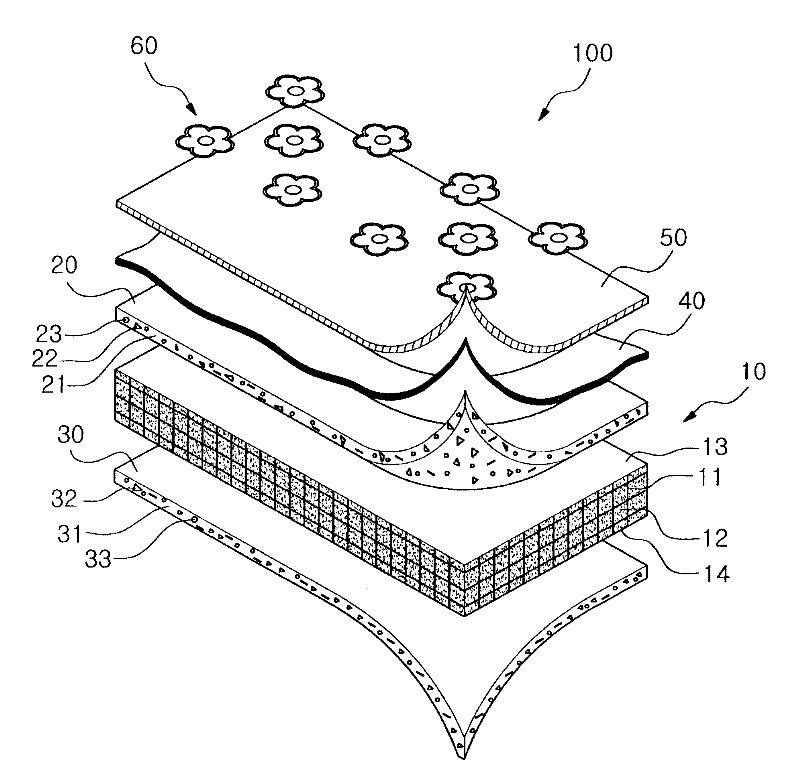

[0105] Embodiment 2 is composed of the upper and lower films, the adhesive layer, and the surface treatment layer composed of the base material of the present invention and the upper and lower film formations. On the top of the surface treatment layer produced by the manufacturing method of the present invention, a digitally printed surface is bonded. Tarpaulins for digitally printed sheets;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com