Porous former with high adsorption performance and manufacturing method thereof

A technology of pore forming and adsorption body, which is applied in the field of high adsorption performance porous molding body and its manufacturing. It can solve the problems of high viscosity and difficulty in uniformly dispersing inorganic ion adsorption body, etc., and achieve the effect of high contact efficiency and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0227] 375 g of polyvinylpyrrolidone (PVP, BASF Japan Co., Ltd., Luvitec K30 Powder (trade name)) was dissolved in 4125 g of dimethyl sulfoxide (DMSO, Kanto Chemical Co., Ltd.) to obtain a homogeneous solution. In 4500g of this solution, add 2250g of cerium oxide powder (Iwatani Industrial Co., Ltd.) with an average particle diameter of 30 μm, and use a A bead mill (SC100, Mitsui Mining Co., Ltd.) with zirconia balls was used to pulverize and mix for 30 minutes to obtain a yellow slurry. In addition, 375 g of ethylene-vinyl alcohol copolymer (EVOH, Nippon Synthetic Chemical Industry Co., Ltd., Soamol E3803 (trade name)) was added to the slurry, heated to 60° C. in a dissolution tank, and stirred and dissolved using a stirring blade. , to obtain a homogeneous slurry solution.

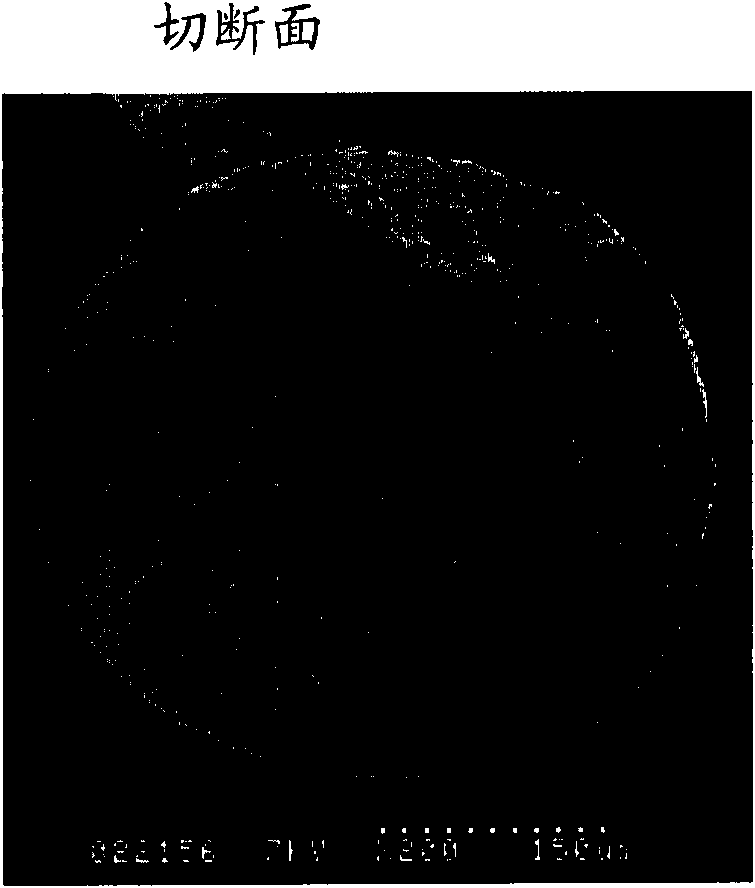

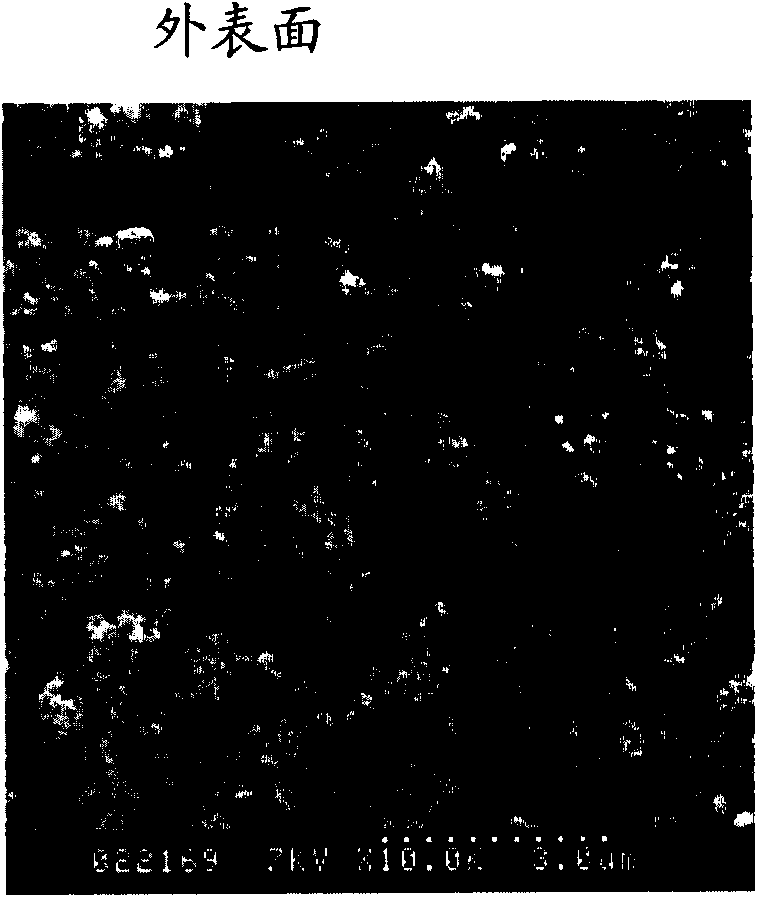

[0228] The obtained polymer slurry was heated to 40° C., and supplied to the inside of a cylindrical rotating container having a nozzle with a diameter of 5 mm on the side, and the container was rotate...

Embodiment 2

[0243] A spherical molded body having an average particle diameter of 600 μm was obtained by the same method as in Example 1 except that the pulverization and mixing treatment time was set to 5 minutes. The physical properties are listed in Table 1.

Embodiment 3

[0245] use diameter Except that the zirconia balls were pulverized and mixed, a spherical molded body with an average particle diameter of 600 μm was obtained by the same method as in Example 1. The physical properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com