A method of holding a dummy bar in a continuous casting device and a continuous casting device having the same

A dummy rod and equipment technology, applied in the field of dummy rod maintenance, can solve problems such as damage to equipment components, casualties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

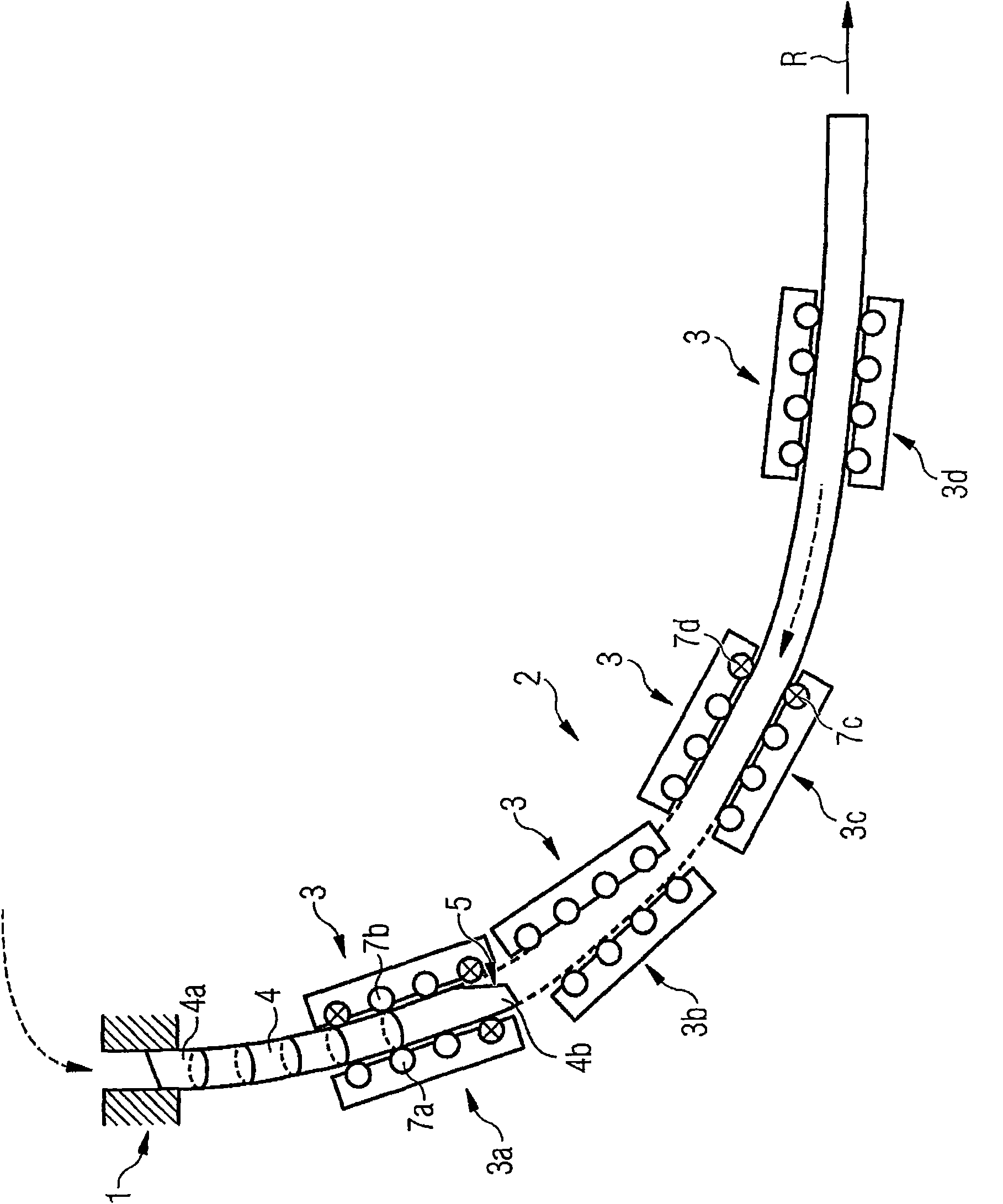

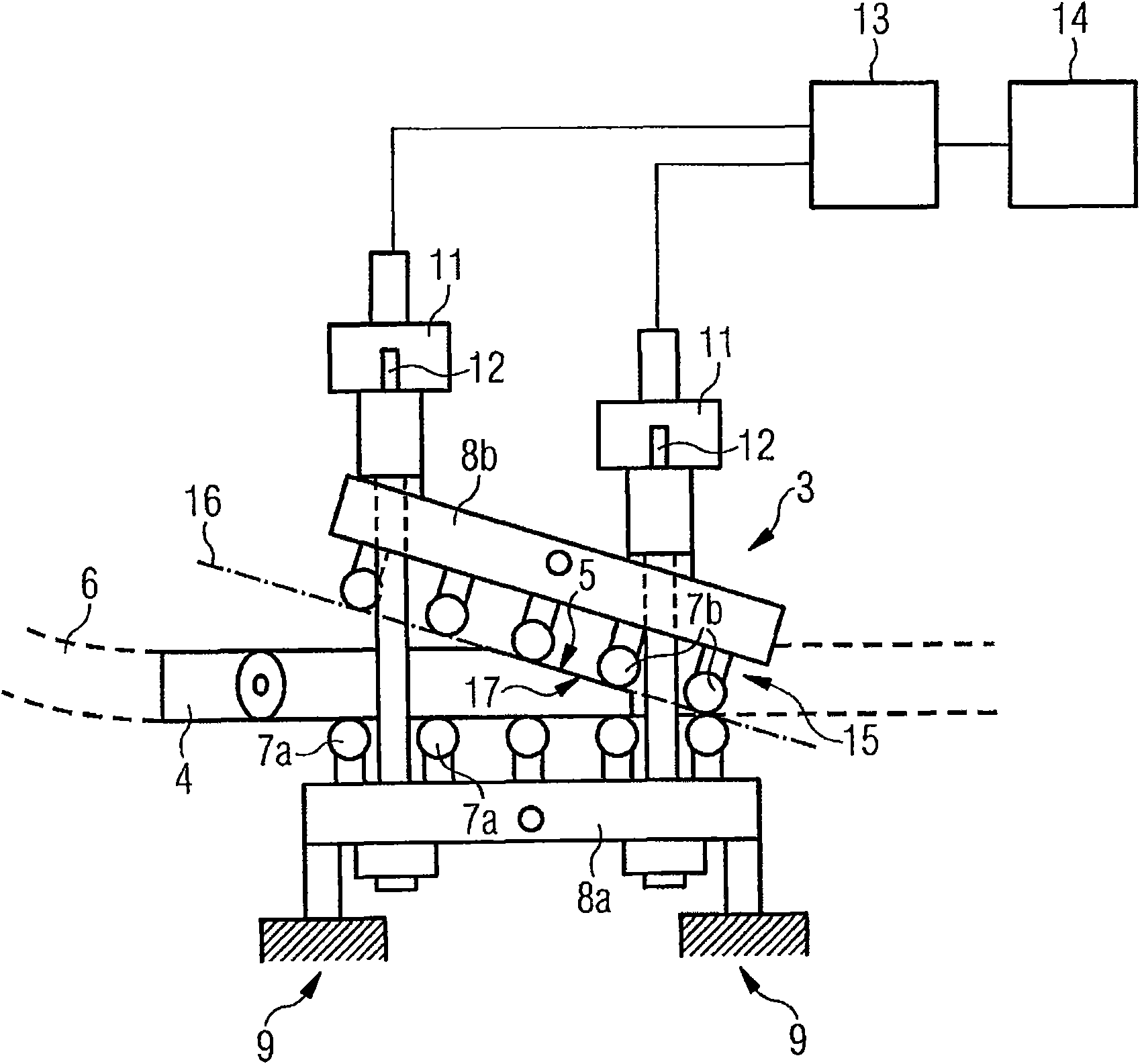

[0020] figure 1 2 schematically shows an arc-shaped continuous casting installation in longitudinal section with the components essential to the invention. The arc-shaped continuous casting equipment includes a continuous casting mold 1 in which the strand is formed from molten metal during the casting process; and the arc-shaped continuous casting equipment includes a continuous casting mold 1 coupled The arc-shaped continuous casting strand guide mechanism 2, in which the continuous casting strand is continuously cooled, and is diverted from the substantially vertical casting direction to the horizontal conveying direction. The strand guiding mechanism 2 is formed by a row of strand guiding segments 3 , of which four strand guiding segments 3 a , 3 b , 3 c , 3 d are shown as a representative. The dummy bar 4 formed by the link chain is shown in its starting position, which is occupied by the dummy bar 4 at the start of casting, and in which it is The spindle head 4a protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com