Water jacket of engine cylinder

A technology for engine cylinders and water jackets, which is applied in the direction of engine components, machines/engines, cylinders, etc., to achieve the effects of improved cooling effect, reasonable design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

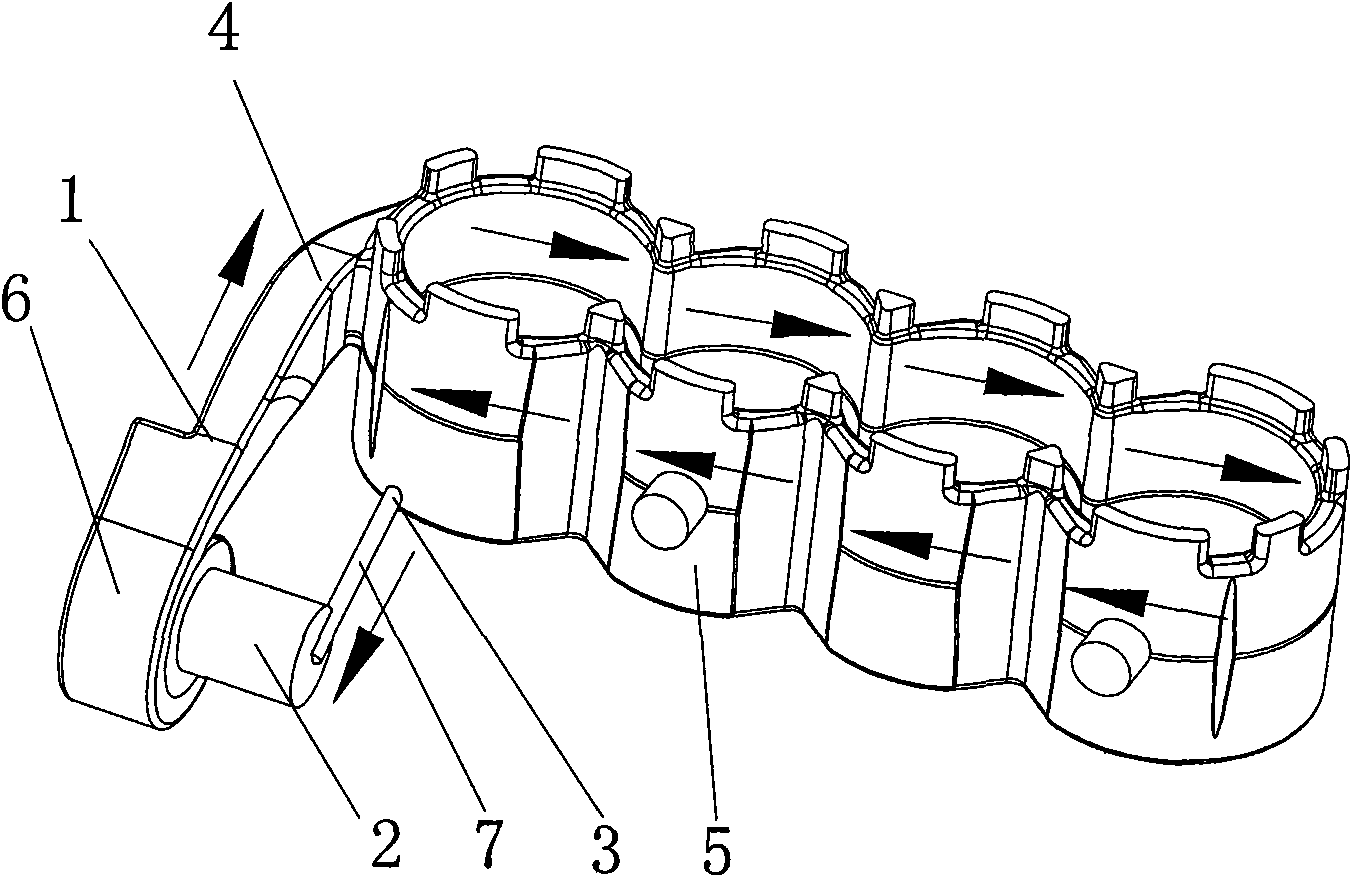

[0012] Example 1, such as figure 1 Shown, a kind of engine cylinder block water jacket, it comprises the annular cylinder block water jacket 5 and the water pump 6 that are arranged between the cylinder block and the cylinder liner and are enclosed by the intake side water jacket and the exhaust side water jacket. The water pump outlet 1 cuts into the outlet 4 of the water jacket on the exhaust side. There is a set of water holes on the exhaust side cylinder head on the water jacket on the exhaust side, and a group of water holes on the cylinder head on the intake side on the water jacket on the intake side. , the water hole on the nose bridge area cylinder head is also set in the nose bridge area. A water return port 3 is provided on the other side of the air intake side water jacket corresponding to the water inlet port 4 on the exhaust side water jacket, and is connected with the water pump water inlet port 2 through the water return pipe 7 .

[0013] Further, in order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com