Guide rails

A technology of compact racks and guide rails, which is applied in cabinets for storing books, household appliances, applications, etc. It can solve the problems of poor guide rail effect, unsafe use, and influence on appearance and cleanliness, so as to improve installation accuracy, safe and reliable use, and compactness well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

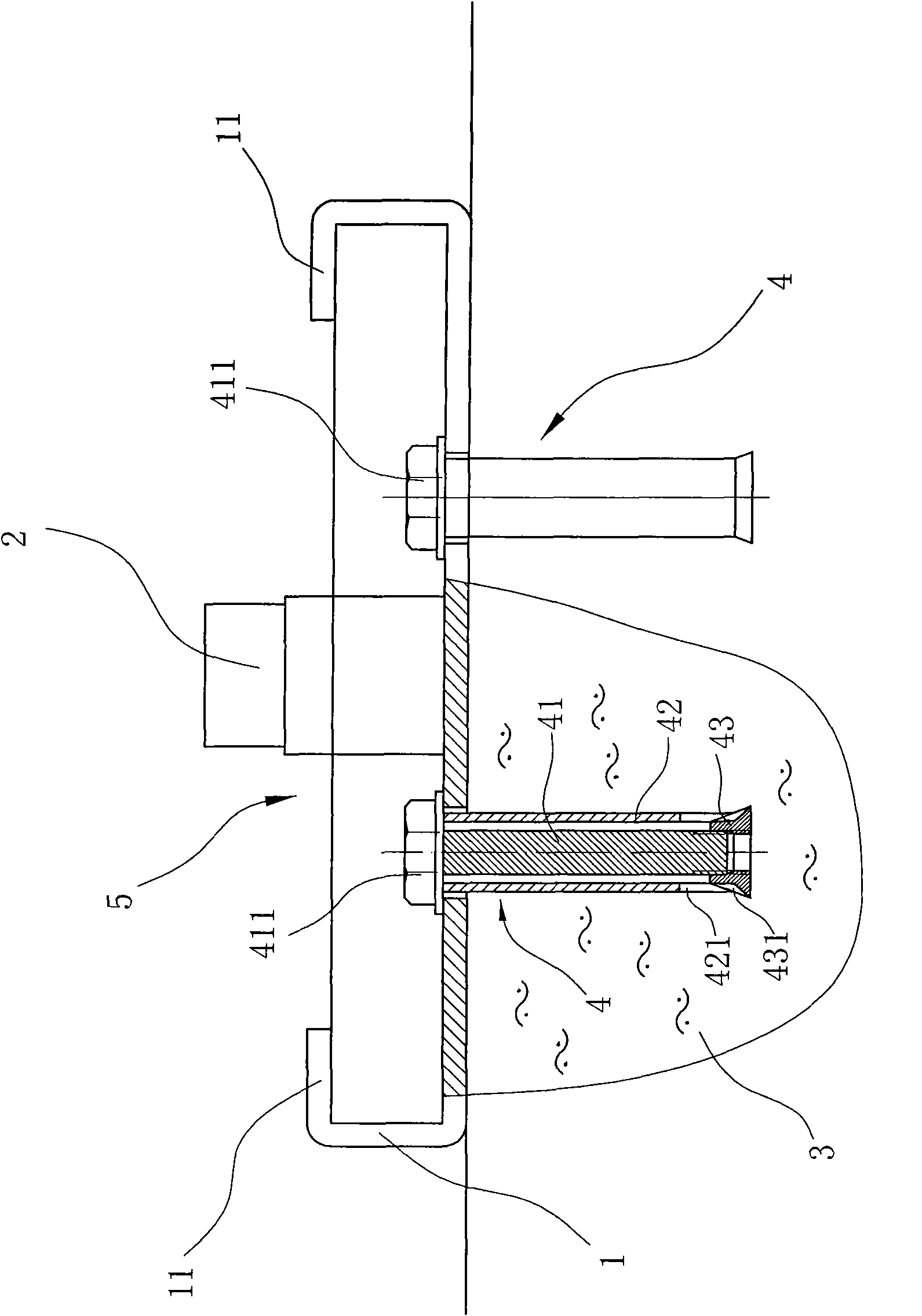

[0020] Such as figure 1 As shown, it is a schematic diagram of the installation structure of the guide rail in this embodiment. The guide rail includes a guide rail seat 1 connected to the foundation 3 and a guide rail 2 connected to the guide rail seat 1 for erecting rollers.

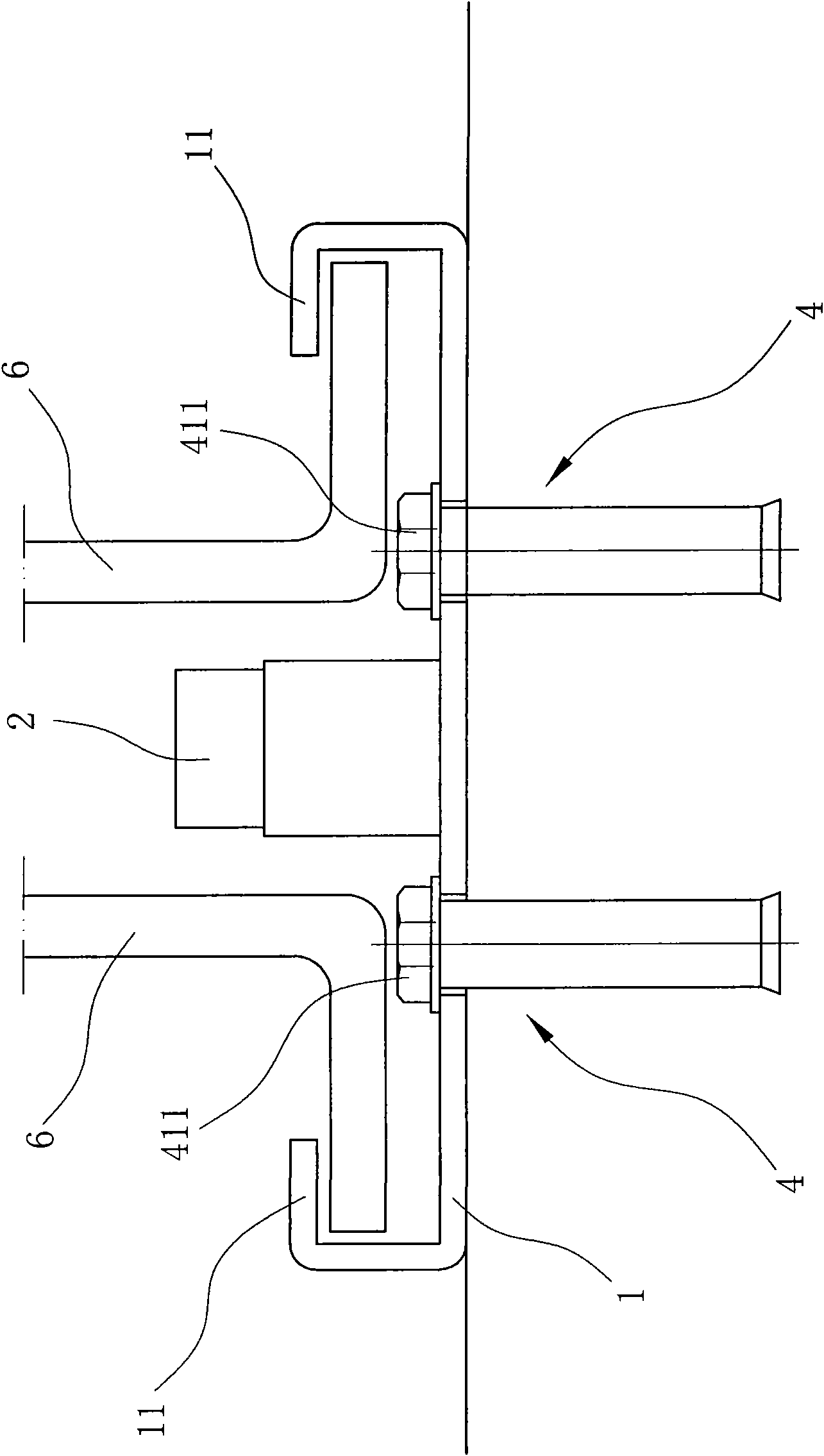

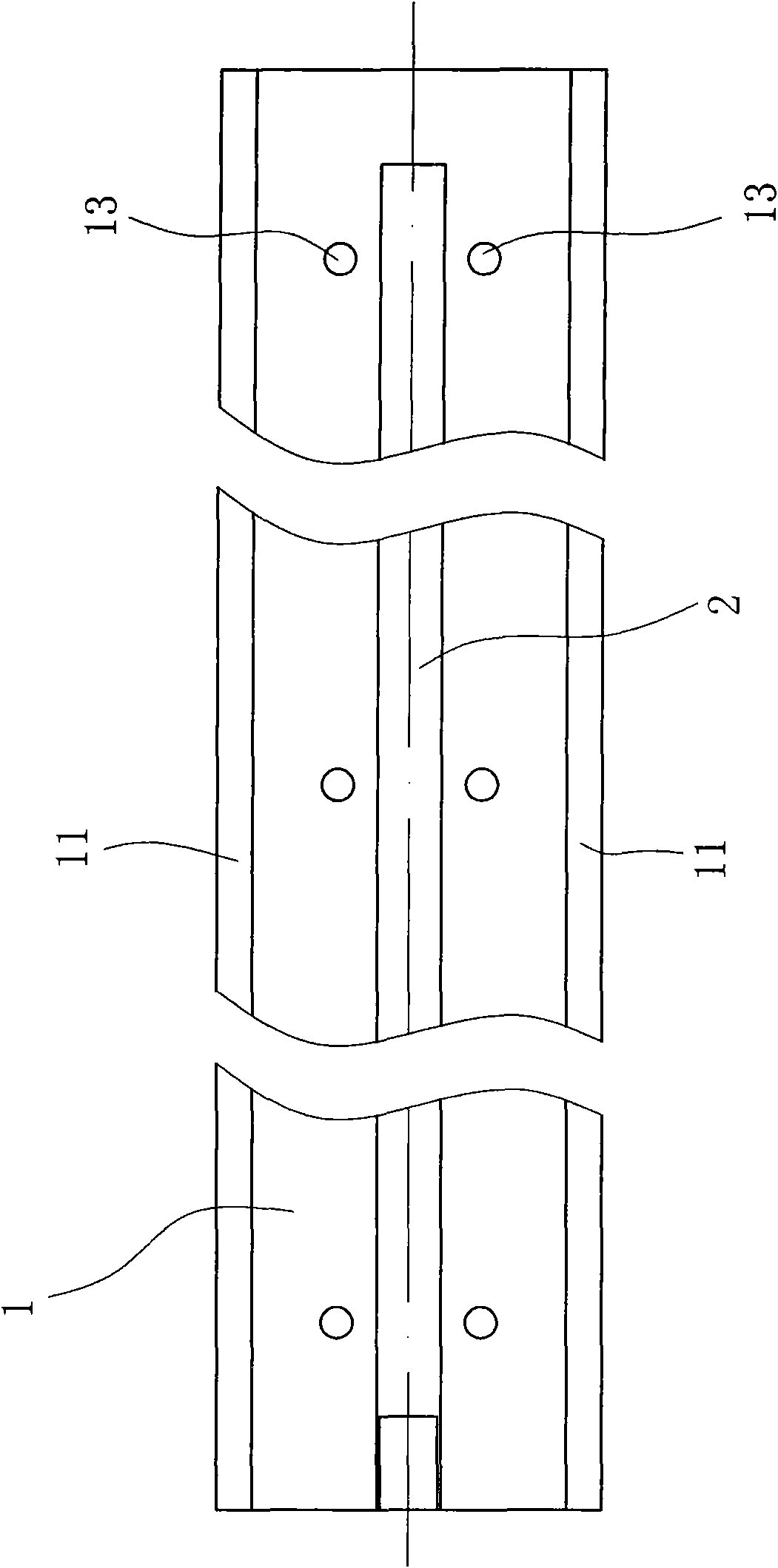

[0021] Such as figure 2 , image 3 with 4 As shown, the bottom surface of the guide rail seat 1 is provided with a plurality of groups of small holes 13 for screw or bolt installation which are located on both sides of the guide rail 2 and are aligned with each other. In order to avoid damage to the exposed screw heads, in this embodiment A compression expansion screw assembly 4 is installed in the hole 13 . The expansion screw 4 includes a screw 41 with a hexagonal head 411 connected to the head, an expansion sleeve 42 sleeved outside the screw 41 and a conical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com