Pneumatic painting apparatus with spray gun, heater device, and dehumidifier/drier device

A spraying device, dehumidifier technology, applied in the direction of spraying devices, liquid spraying devices, chemical instruments and methods, etc., can solve the problems of inconvenient replacement, non-renewable fluid particle mixture optimization, difficult to realize, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

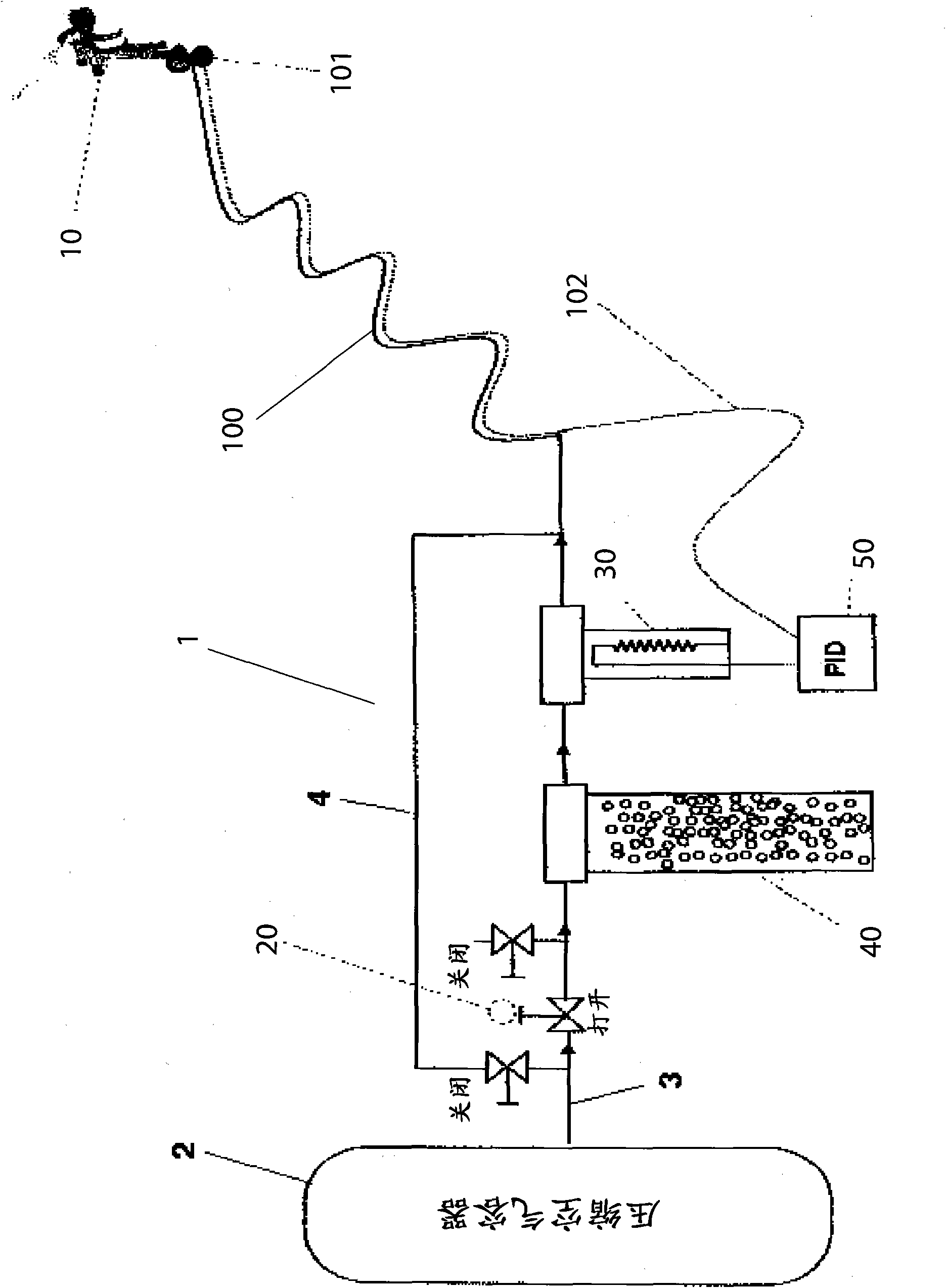

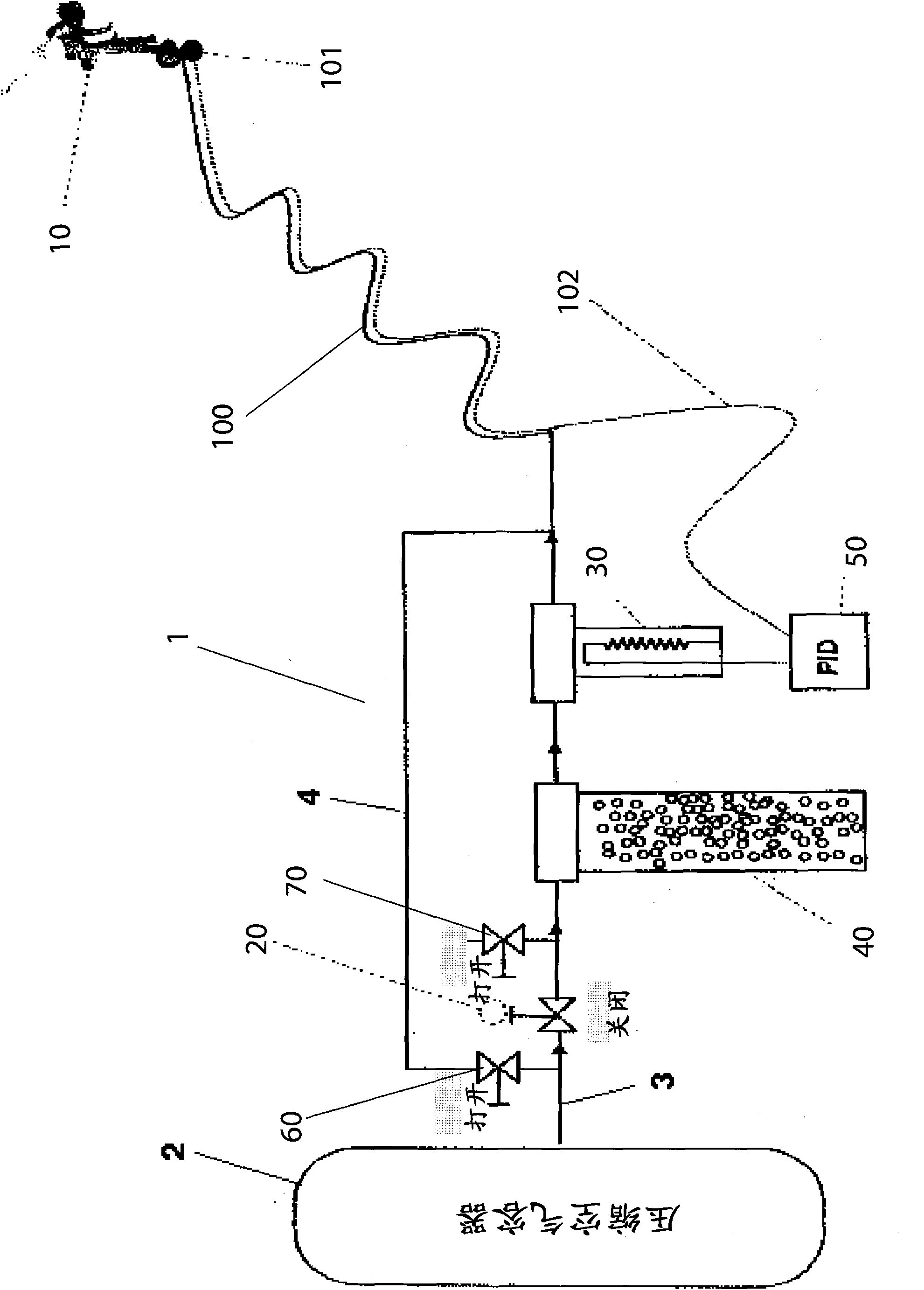

[0075] The object of the present invention is a spraying device 1 of the pneumatic type having a spray gun 10 with a heater device 30 of air flow under pressure and a dehumidifier / dryer 40 provided with a regeneration device 4 containing an adsorbent containing In the dehumidifier / dryer 40, it is used to fluidize the coating during application to the support.

[0076] Such as figure 1 As shown, the spraying apparatus 1 comprises a conventional compressor unit (not shown) fed to a compressed air container 2 . The compressed air container 2 has an outlet for a compressed air flow which is fed into the compressed air flow circuit 3 and conveyed towards at least one spray gun 10 . The circuit 3 is activated by a solenoid valve 20 located between the supply pipe 100 of the spray gun 10 and the compressed air container 2 , passing at least one heater device 30 for the treatment air flow and then conveyed through the supply pipe 100 of the spray gun 10 . In this case there is a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com