Paint film cracking detection method of enamelled wire and detection apparatus

A detection method and enameled wire technology, applied in the direction of using chemical indicators for analysis, etc., can solve the problems of inability to determine, eyes are easily fatigued, and it is impossible to comprehensively and accurately determine the cracking state of the paint film, so as to reduce eye fatigue and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

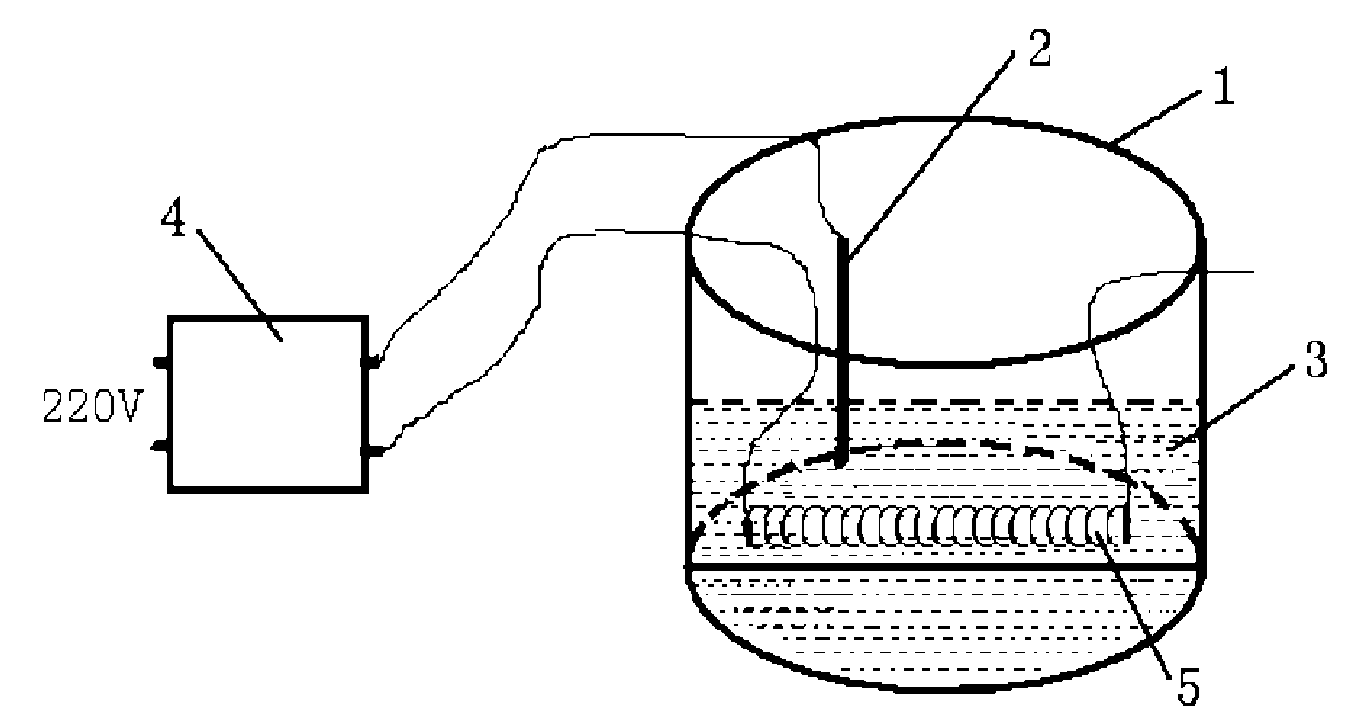

[0013] Example 1. Such as figure 1 As shown, it includes a container 1 and an electrode 2. The container 1 contains a saline phenolphthalein solution 3, one end of the electrode 2 is immersed in the saline phenolphthalein solution 3, and the other end of the electrode 2 is connected to an adjustable external power supply 4. The concentration of the salt water phenolphthalein solution 3 is the same as the solution concentration specified in the national standard for enameled wire salt water test. The mass percentage concentration of the salt water phenolphthalein solution 3 is 0.2% sodium chloride, 0.3% phenolphthalein, and the rest is water; The power supply 4 selects a 12V DC voltage power supply, which is the same as the voltage specified in the national standard for enameled wire salt water test. When testing, immerse the enameled wire winding sample 5 to be tested in the salt water phenolphthalein solution 3, and connect the enameled wire winding sample 5 in series with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com