Blue-light-proof protective lens for driving and its manufacturing method

A technology for goggles and anti-blue light, applied in glasses/goggles, optics, optical components, etc., can solve the problems of inability to reduce retinal damage and ineffective control, so as to protect eye health, improve visual ability, reduce The effect of eye strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0045] The anti-blue light driving goggle lens in this specific embodiment consists of two parts: a substrate containing an ultraviolet light absorber and an evaporated film layer. The substrate is a refractive lens made of polycarbonate containing a short-wave visible light absorber, or it can be made of polymethyl methacrylate, allyl diglycol carbonate and diisopropyl peroxycarbonate copolymer. Any kind of prepared refractive lens. The vapor-deposited film layer is composed of three layers of alternately stacked layers, from the inside to the outside are SiO 2 film, ZrO film and SiO 2 The film layer has a thickness of 145nm.

[0046] SiO in this specific embodiment 2 The film layer is a low refractive index film layer, and the ZrO film layer is a high refractive index film layer.

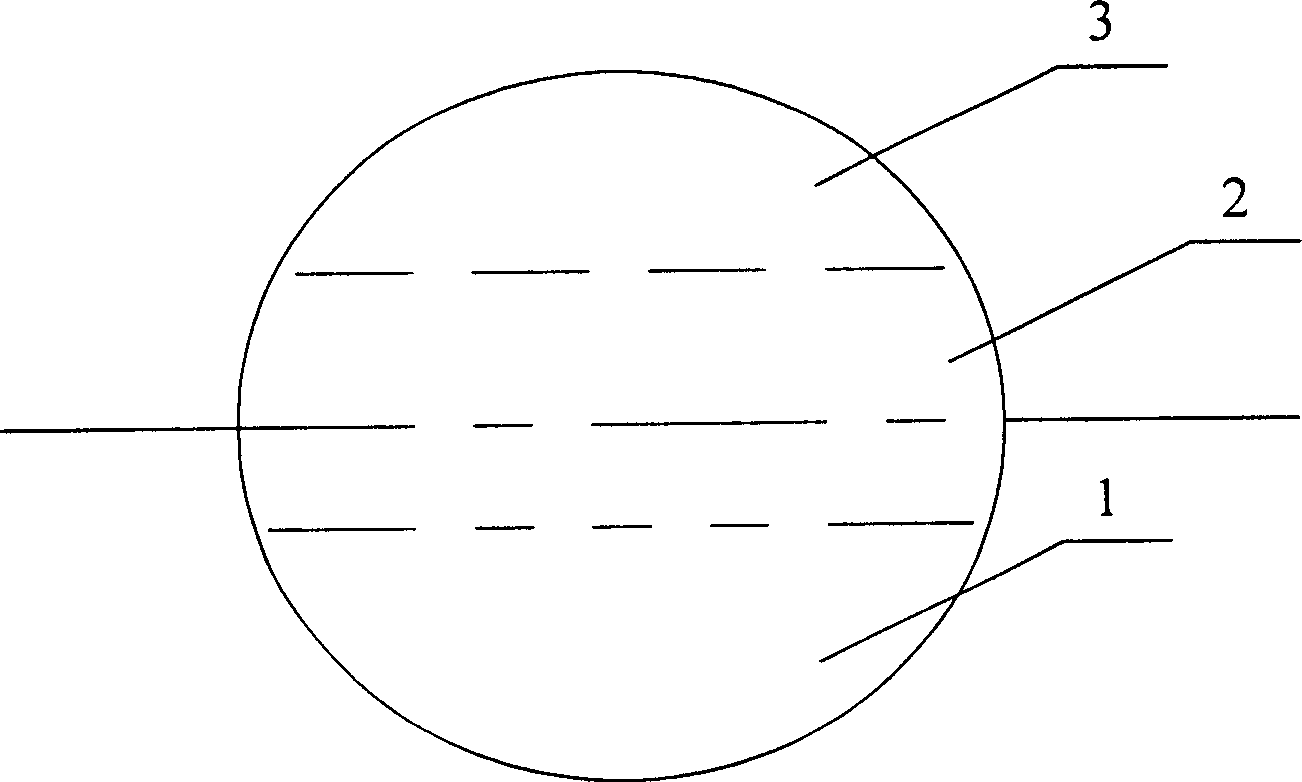

[0047] The short-wave visible light absorbers in this specific example are disperse yellow, disperse blue and disperse red. Such as figure 1 As shown, due to the different content, the subst...

specific Embodiment 2

[0050] The anti-blue light driving goggle lens in this specific embodiment consists of two parts: a substrate containing an ultraviolet light absorber and an evaporated film layer. The substrate is a refractive lens made of polymethyl methacrylate containing a short-wave visible light absorber, or it can be made of polycarbonate, allyl diglycol carbonate and diisopropyl peroxycarbonate copolymer. Any kind of prepared refractive lens. The vapor-deposited film layer is composed of five layers of film layers stacked alternately, from the inside to the outside are SiO 2 film, ZrO film, SiO 2 film, ZrO film and SiO 2 The film layer has a thickness of 195nm.

[0051] SiO in this specific embodiment 2 The film layer is a low refractive index film layer, and the ZrO film layer is a high refractive index film layer.

[0052] The short-wave visible light absorbers in this specific embodiment are disperse yellow, disperse blue and disperse red. Due to the different contents, the sub...

specific Embodiment 3

[0053] The anti-blue light driving goggle lens in this specific embodiment consists of two parts: a substrate containing an ultraviolet light absorber and an evaporated film layer. The substrate is a refractive lens made of allyl diglycol carbonate and diisopropyl peroxycarbonate copolymer containing short-wave visible light absorbers, or it can be made of polycarbonate or polymethyl methacrylate. Any kind of prepared refractive lens. The vapor-deposited film layer is composed of five layers alternately stacked, from the inside to the outside, the TiO2 film layer and the SiO2 film layer are alternated, and the thickness is 150nm.

[0054] The short-wave visible light absorbers in this specific embodiment are disperse yellow, disperse blue and disperse red. Due to the different contents, the substrate is divided into gray strong light blocking area, blue-green main viewing area and yellow-green enhancing area from top to bottom. There are three parts in the transparent area. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com