Pressure reducing valve for gas

A pressure reducing valve and gas technology, applied in the direction of fluid pressure control, balance valve, valve device, etc., can solve the problems of large-scale main body and increase in the number of parts, and achieve cost reduction, cost reduction, and prevention of main body temperature reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

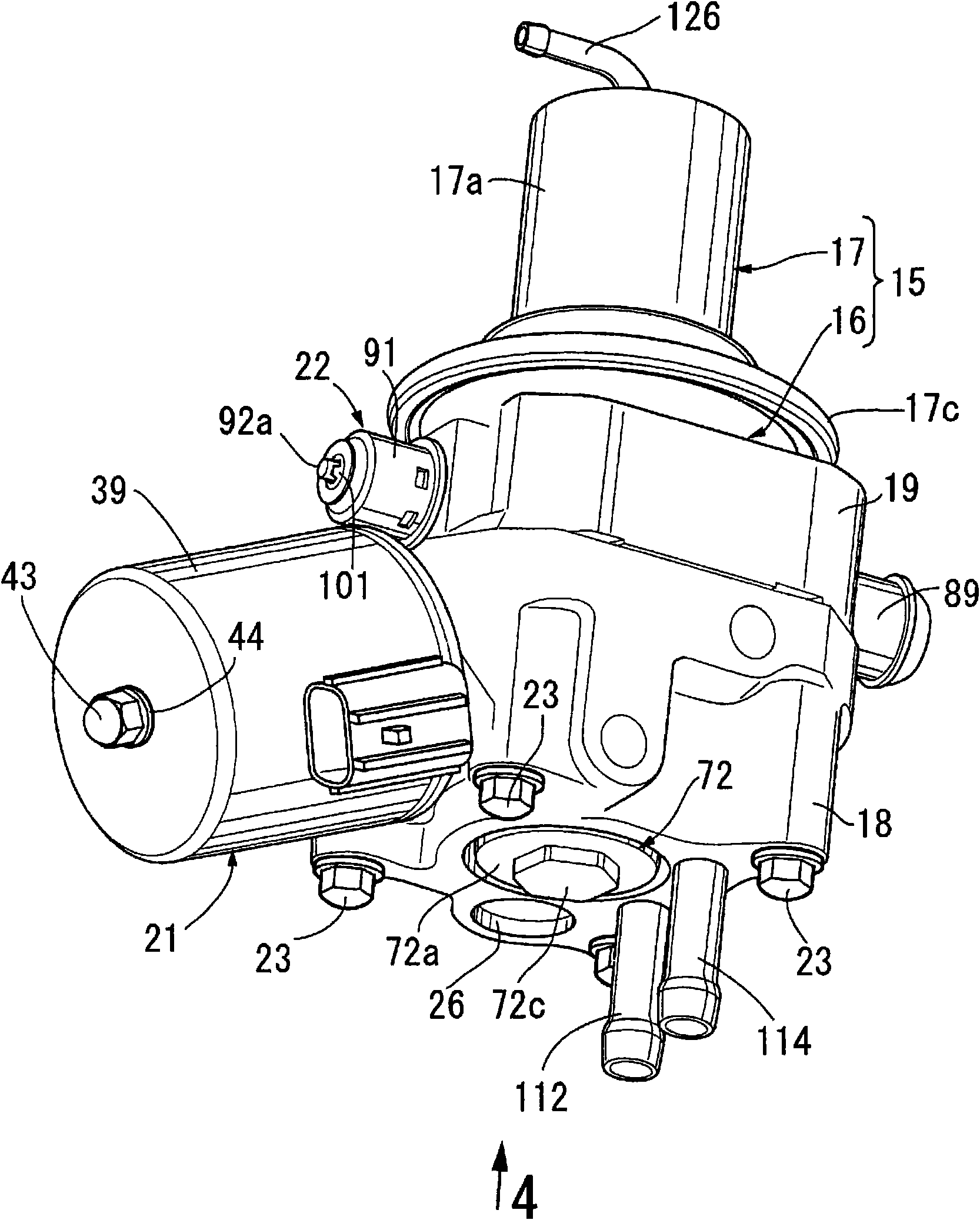

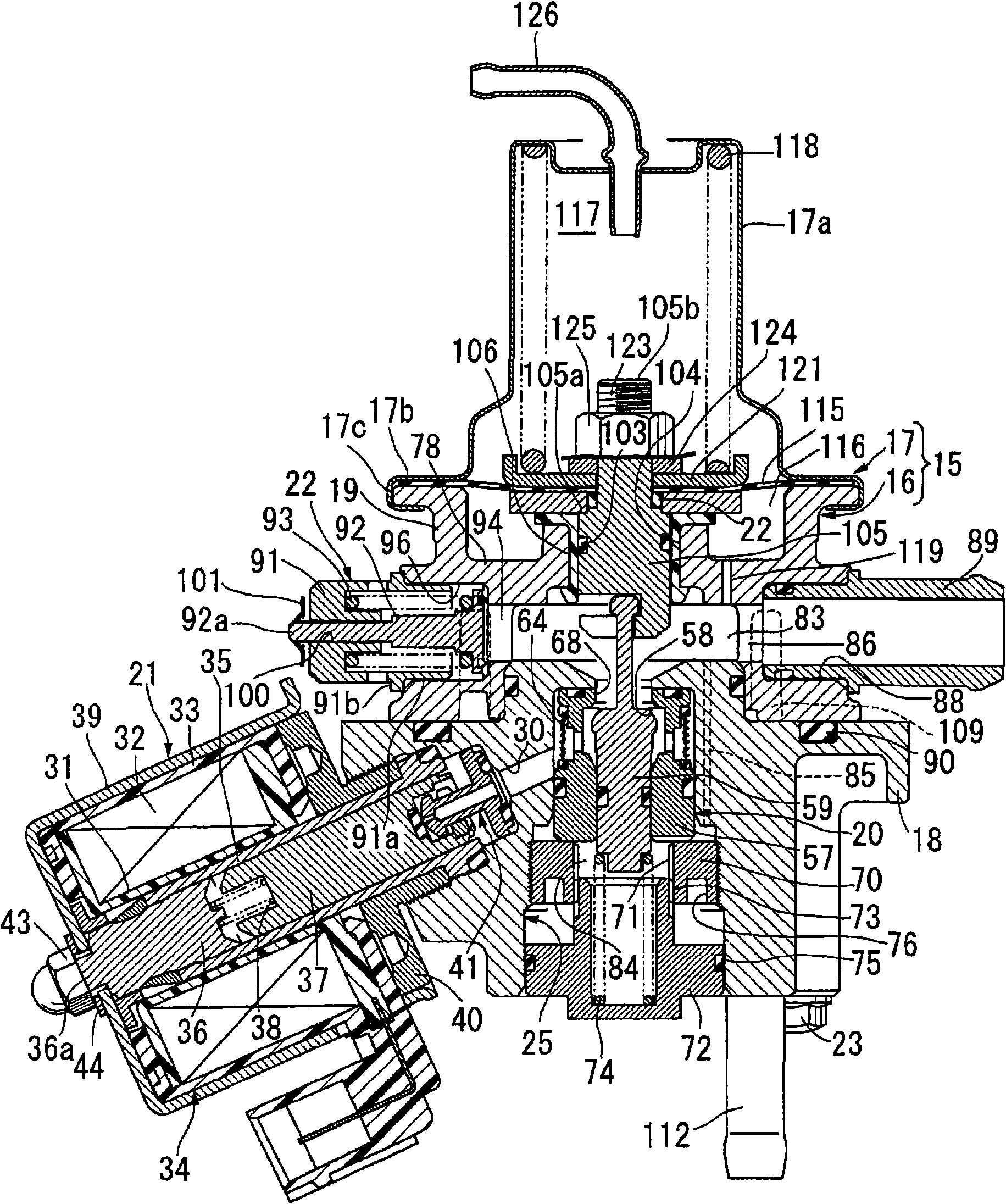

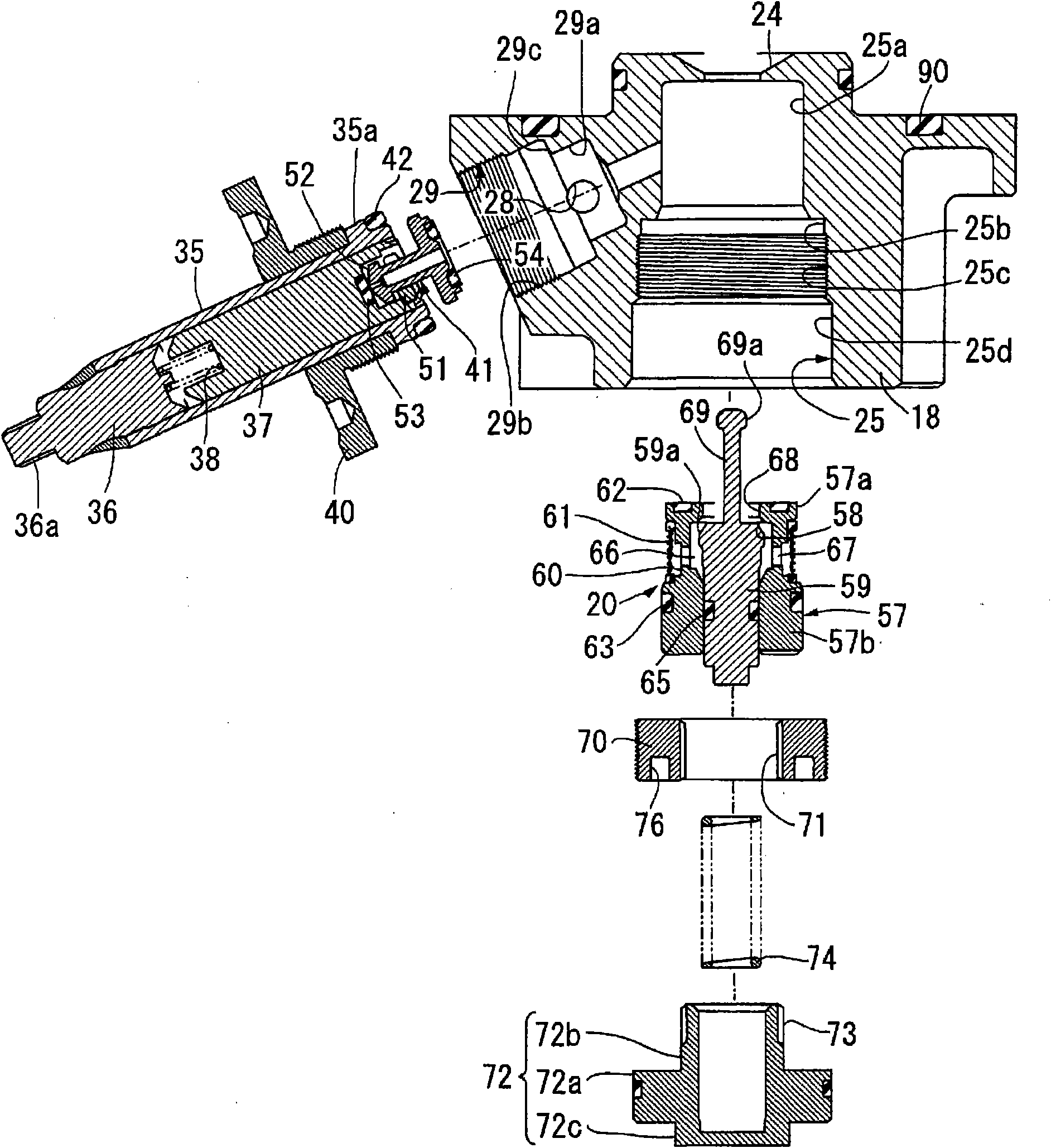

[0046] Figure 1 to Figure 11 A first embodiment of the invention is shown.

[0047] First, in figure 1 Among them, the pressure reducing valve for gas is used to depressurize compressed natural gas as fuel gas and supply it to an engine (not shown). The main body 16 formed by joining the second main body parts 19 with each other; and the diaphragm cover 17 joined to the main body 16, in which the valve mechanism 20 is accommodated (refer to figure 2 ), and is equipped with an electromagnetic cut-off valve 21 and a relief valve 22.

[0048] exist figure 2 Among them, the main body 16 is composed of a plurality of main body parts with different strengths (in this embodiment, a high-strength first main body part 18 and a low-strength second main body part 19) overlapping up and down and using multiple (for example, four) ) Bolts 23, 23... are formed by jointing each other. The first main body part 18 is formed by cutting and forming, for example, a drawn material made of a...

no. 2 example

[0119] Figure 12 and Figure 13 A second embodiment of the present invention is shown.

[0120] First, in Figure 12 Among them, the housing 15' of the pressure reducing valve for gas is composed of a main body 16' and a diaphragm cover 17. The main body 16' is formed by joining a first main body part 18' and a second main body part 19', and the membrane The sheet cover 17 is joined to the main body 16 ′, and the valve mechanism 20 is accommodated in the main body 16 ′, and an electromagnetic shutoff valve 21 and a relief valve 22 are arranged therein.

[0121] The main body 16' is composed of a plurality of main body parts with different strengths (in this embodiment, a high-strength first main body part 18' and a low-strength second main body part 19') overlapping up and down and utilizing four screws 23, 23 ... are formed by jointing each other. The first main body part 18' is formed by cutting a drawn material made of aluminum alloy, or is formed by cutting corners aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com