Crystallization device for smelting copper

The technology of a crystallization device and a transmission device is applied in the field of smelting copper bars and can solve problems such as difficulty in smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

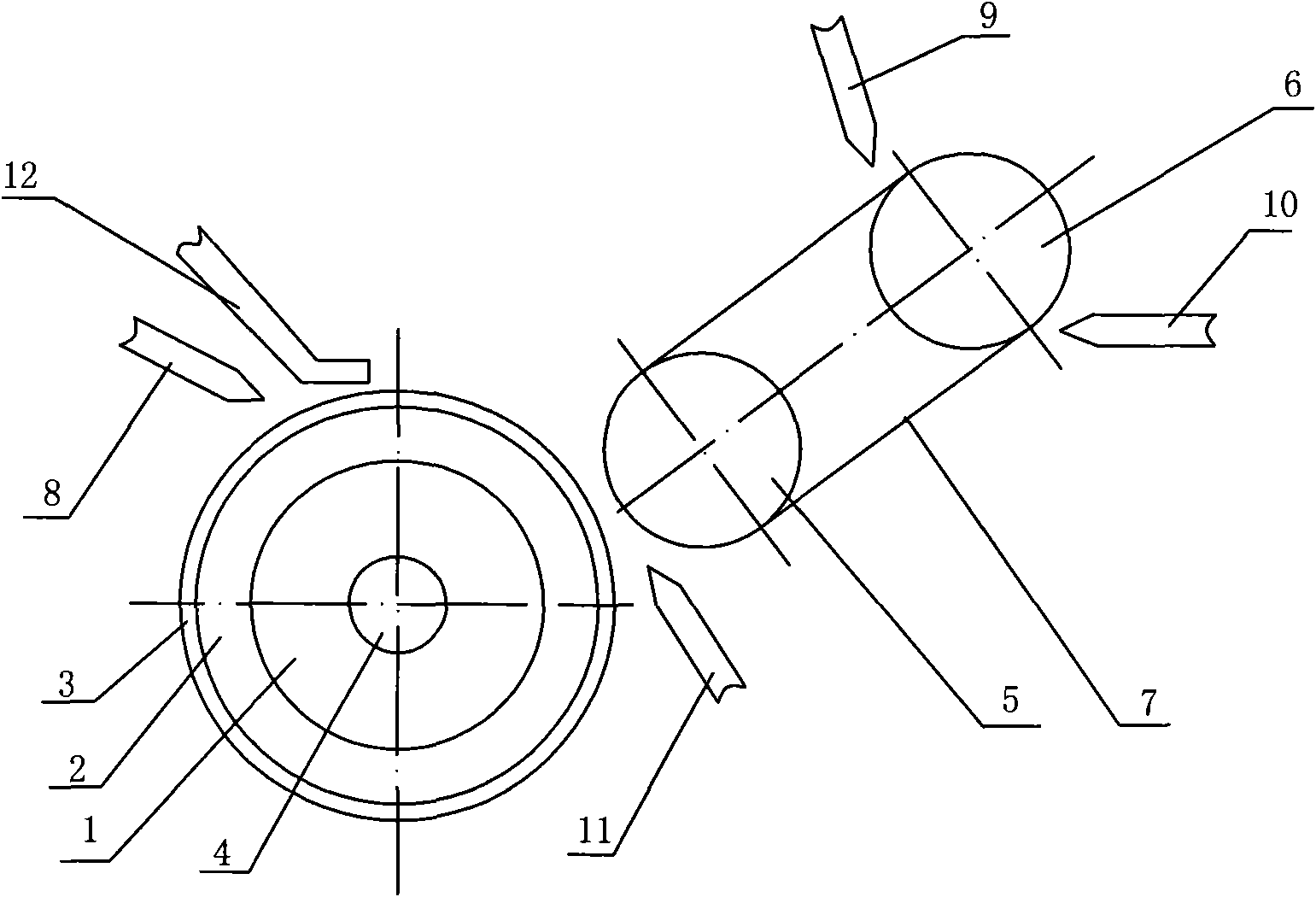

[0007] Such as figure 1 As shown, a water storage chamber 2 is provided in the inner cavity of the wheel body 1 , an annular groove 3 is arranged on the outer surface of the wheel body 1 along the circumferential direction, and a transmission device 4 is connected to the central axis of the wheel body 1 .

[0008] A pair of driving wheels 5 and 6 are arranged on one outer side of the wheel body 1 , and the annular molding bead 7 surrounds the outside of the driving wheels 5 and 6 , and an acetylene nozzle 8 is arranged on the other side of the wheel body 1 . A pouring port 12 is provided above the acetylene nozzle 8 .

[0009] Another acetylene injection nozzle 9 and an oxygen filling nozzle 10 are arranged on the outside of the molding bead 7 away from the wheel body 1 .

[0010] A cold water nozzle 11 is arranged on the other outside of the molding bead 7 close to the wheel body 1 .

[0011] Pouring copper water at a constant speed from the pouring port 12 to the annular g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com