Electric chain saw

An electric chain saw and motor shaft technology, which is applied to chainsaws, sawing equipment, sawing machine devices, etc., can solve the problems of operator danger, disadvantageous miniaturization of electric chain saws, complex structure, etc. The effect of miniaturized design and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

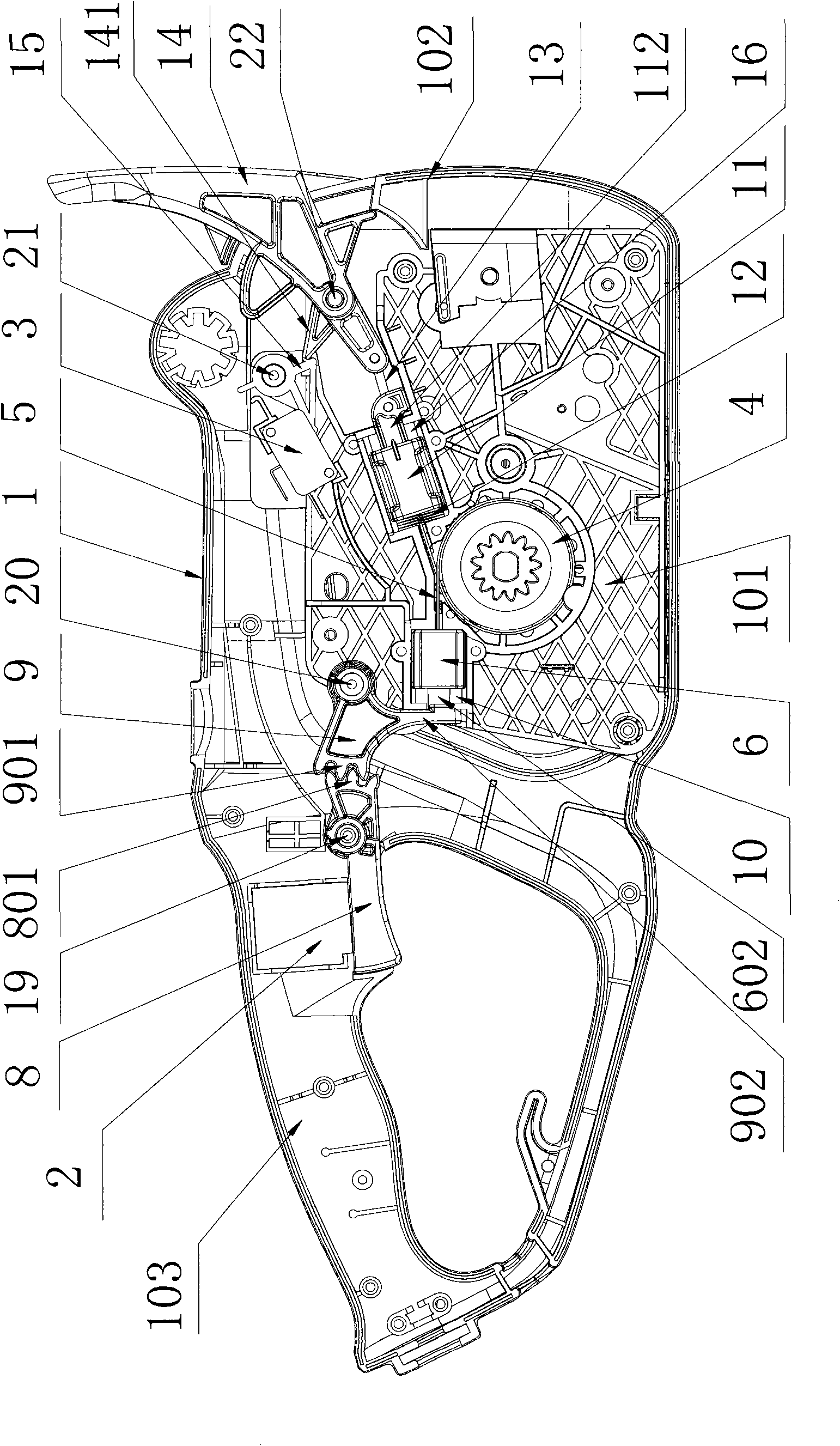

[0052] Embodiment: The technical solution of the present invention will be further described below in conjunction with the accompanying drawings through the embodiments.

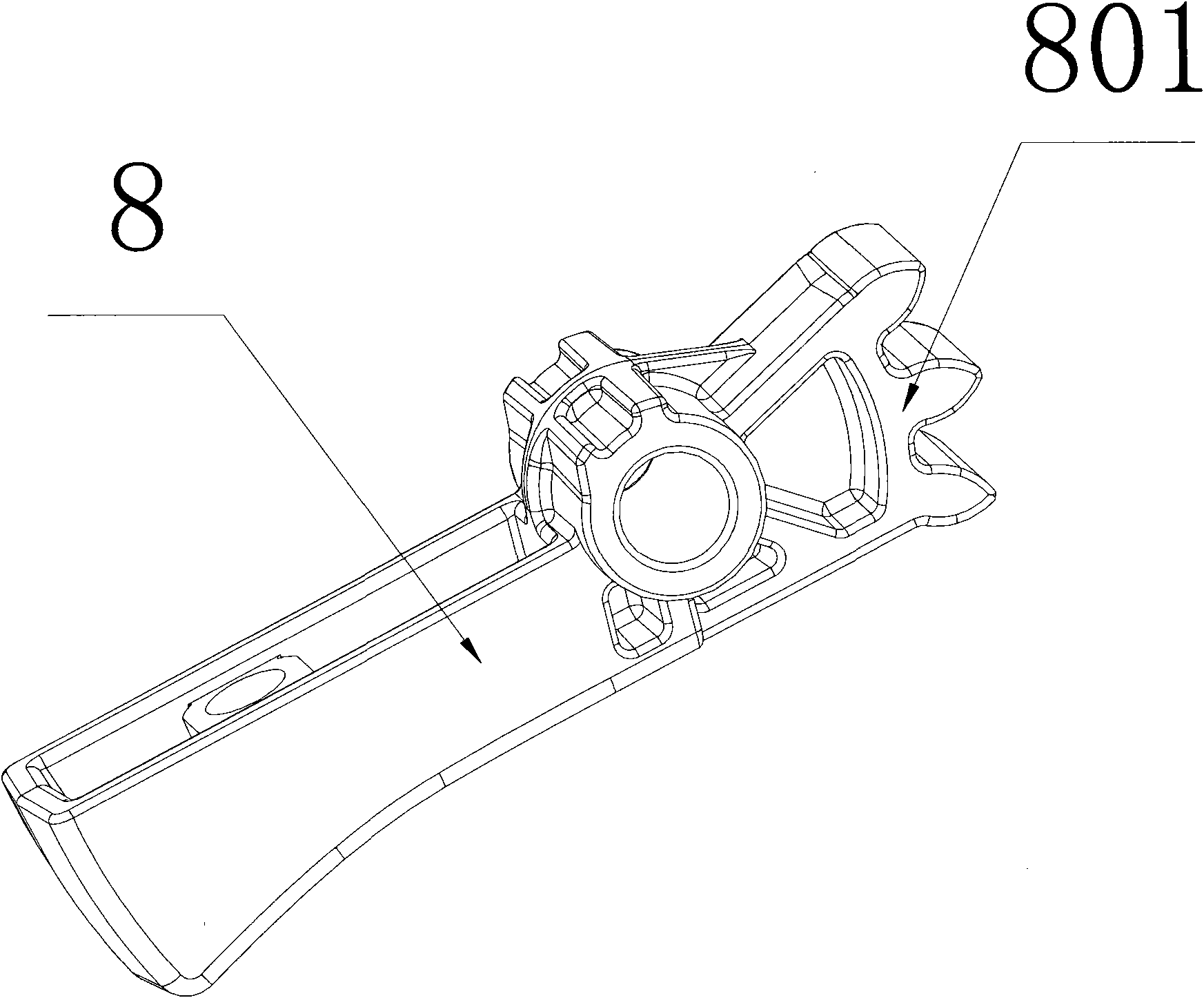

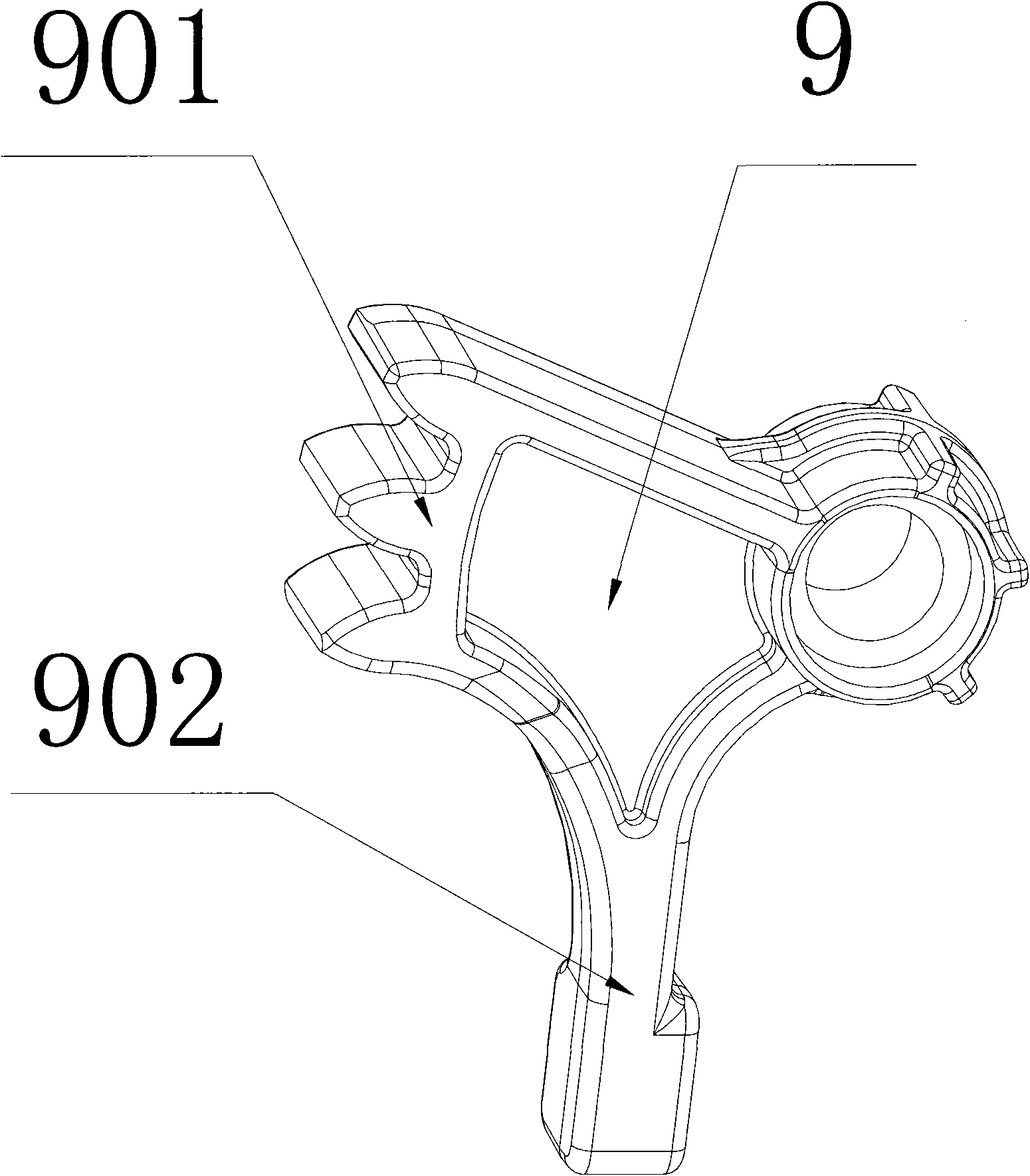

[0053] Such as figure 1 Shown is a kind of specific embodiment of electric chain saw of the present invention, and this electric chain saw comprises casing 1, the motor that is located in casing 1, the chain saw blade (not shown in the drawing) driven by motor shaft and installation The brake device in the casing 1, the casing 1 is composed of the casing body 101 and the front and rear handles 102, 103 which are integrated with the casing body 101; the rear handle 103 is provided with a main power switch 2, and the casing The motor and the protective power switch 3 are arranged in the main body 101 , and the motor, the main power switch 2 and the protective power switch 3 are connected in series. The brake device is composed of a brake drum 4, a brake band 5, a first brake unit and a second brake unit; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com