Retainer for deep groove ball bearing with grease holes and deep groove ball bearing

A deep groove ball bearing and cage technology, applied in the field of bearings, can solve the problems of affecting the normal operation of the bearing, difficulty in entering the lubricating medium, fracture of the cage, etc., achieve good and reliable running quality, improve lubrication performance, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

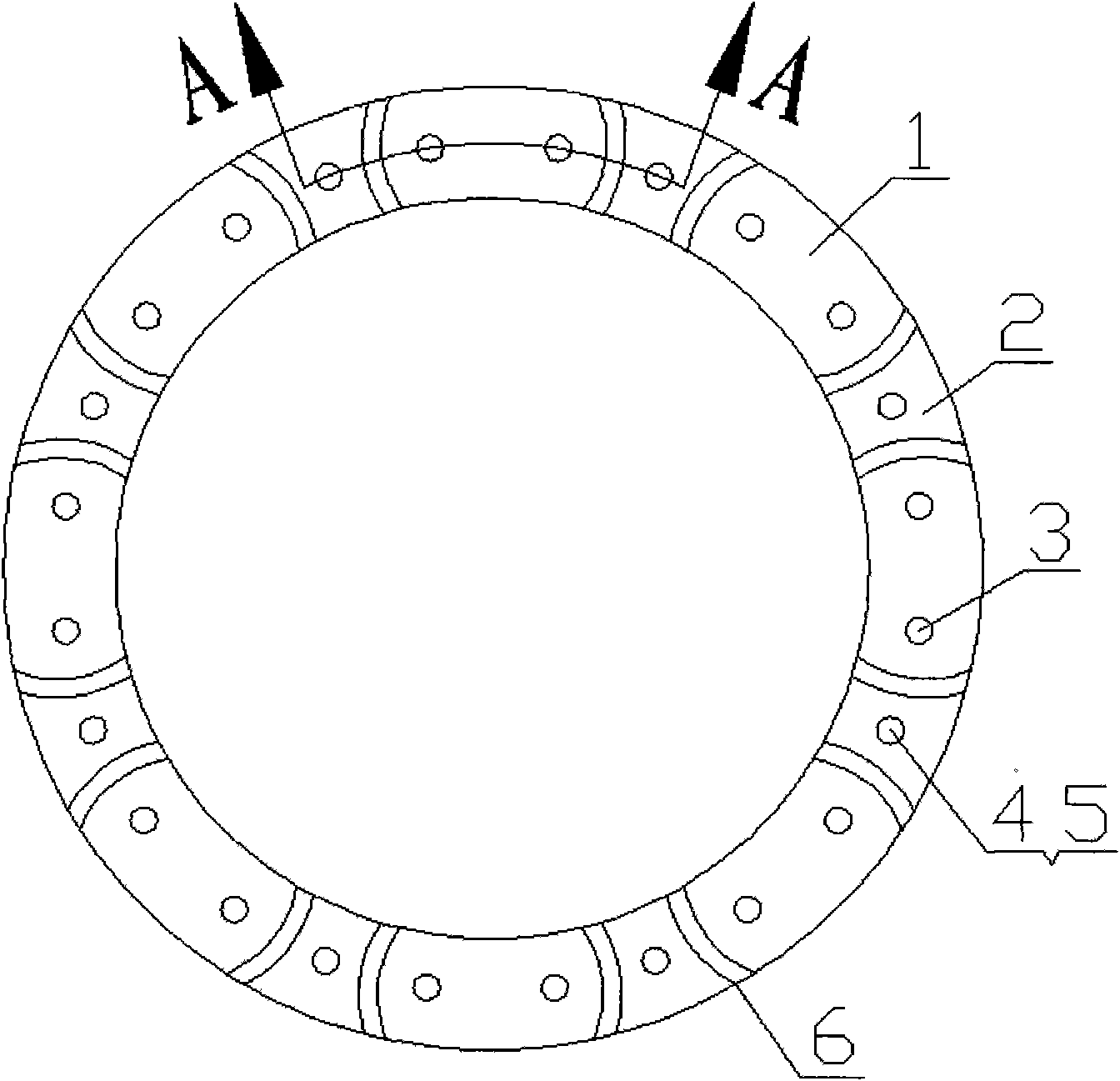

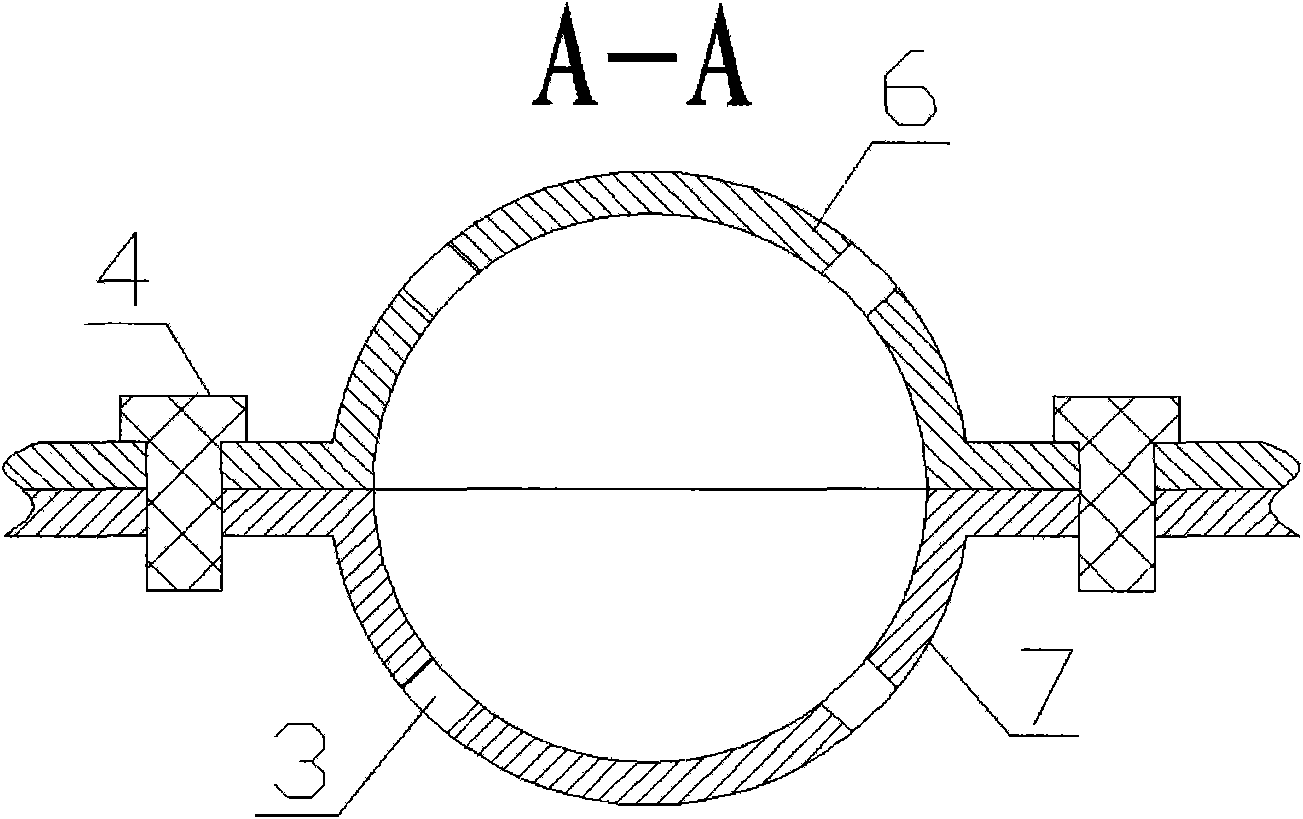

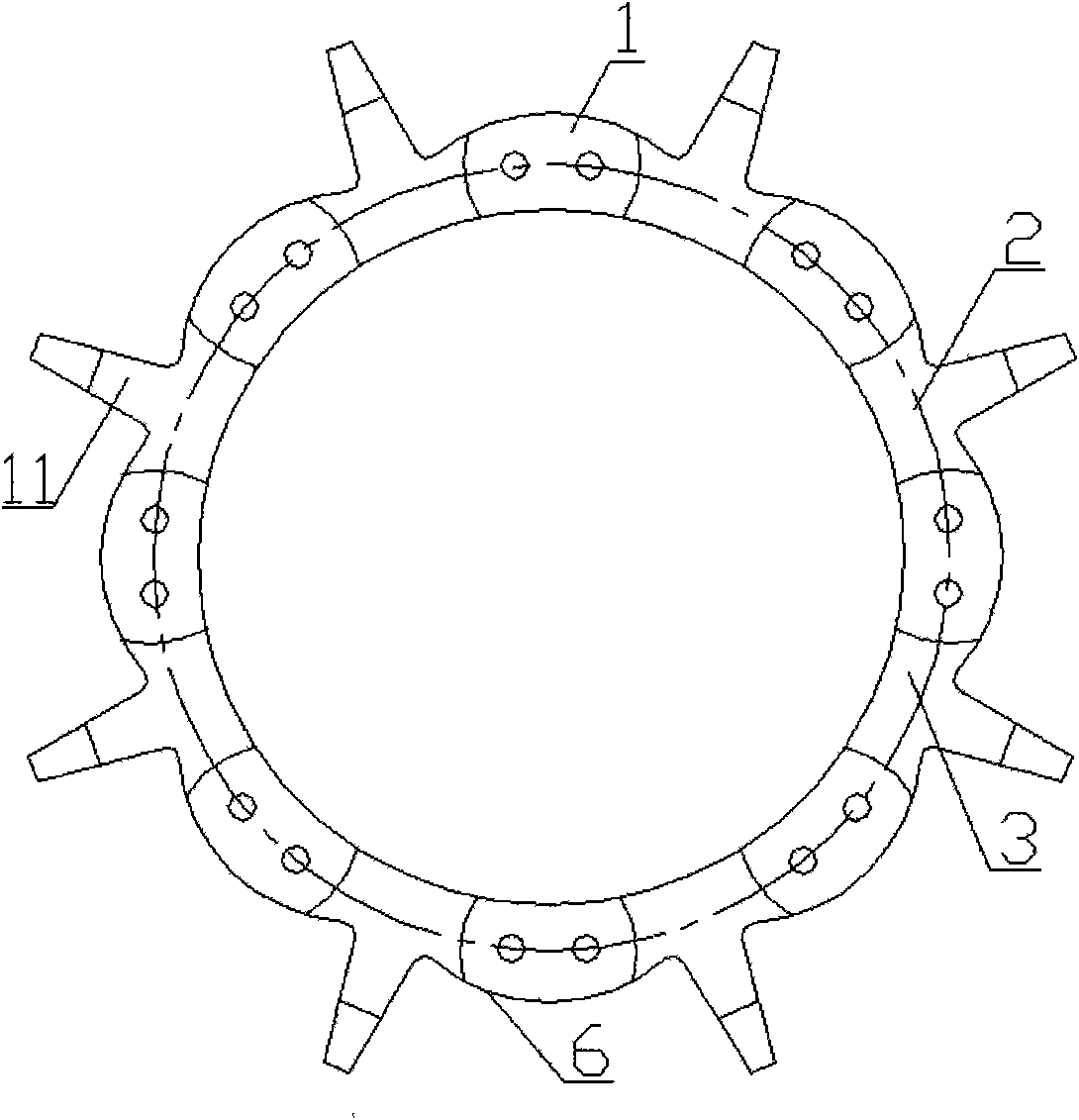

[0016] Such as figure 1 with figure 2 As shown, it is a structural diagram of an embodiment of the cage of the present invention. During implementation, its design main mechanism includes a ball pocket 1, a plane 2, a grease hole 3, a rivet 4, a rivet hole 5, a frame body I 6 and a frame body II 7 . Among them, frame body I 6 and frame body II 7 include alternately arranged ball pockets 1 and planes 2, rivets 4 are welded on frame body I 6, rivet holes 5 are arranged on frame body II 7, frame body I 6 and frame body II 7 can be docked together. A pair of grease holes 3 are provided on the surface of the ball pocket 1 of the frame body I 6 and frame body II 7, and the grease holes 3 are symmetrically arranged on both sides of the apex of the A-A arc section, and the A-A arc section Centerline coincides with the axis of frame body 16, and its radius is the vertical distance from the center line of grease hole 3 to the axis of frame body 16, and grease hole 3 is a semicircle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com