Variable resistance dissipative energy absorber

A technology of energy absorber and resistance, applied in the direction of friction shock absorber, etc., can solve the problems of large destructive force, large initial impact energy, short buffer distance, etc., and achieve the effect of avoiding sports car accidents, large energy absorption capacity and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

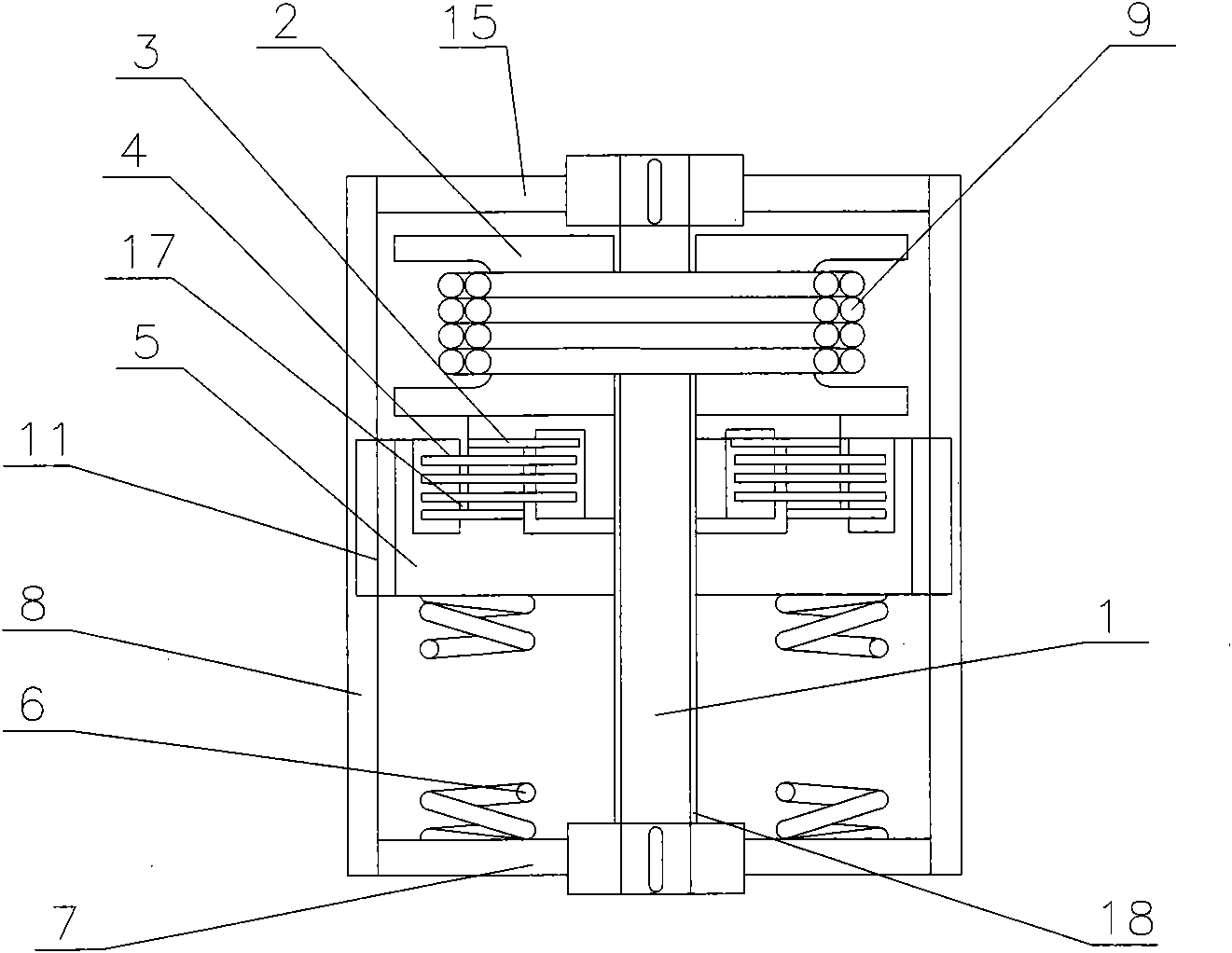

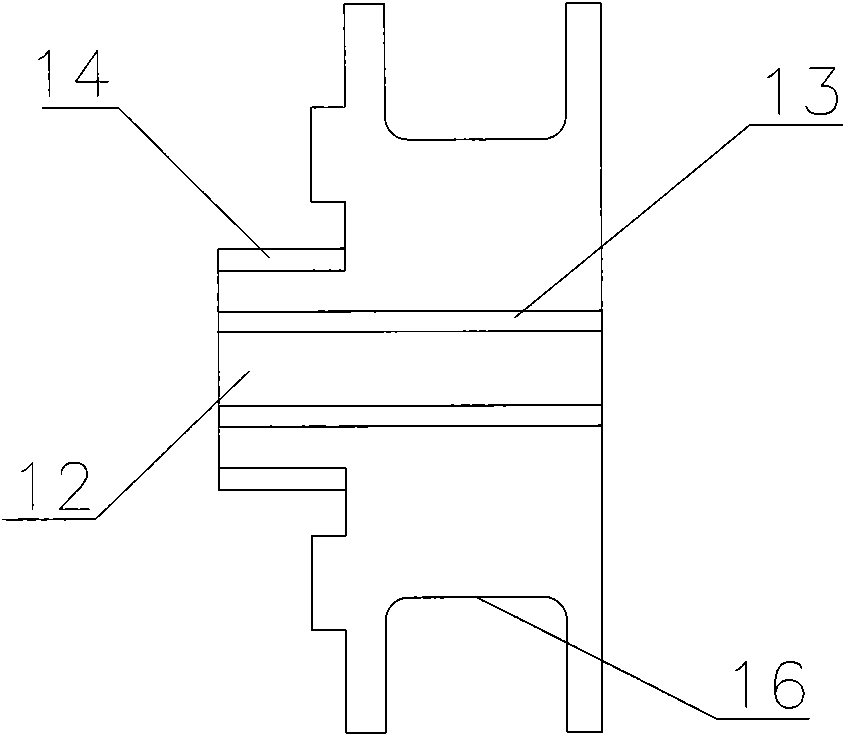

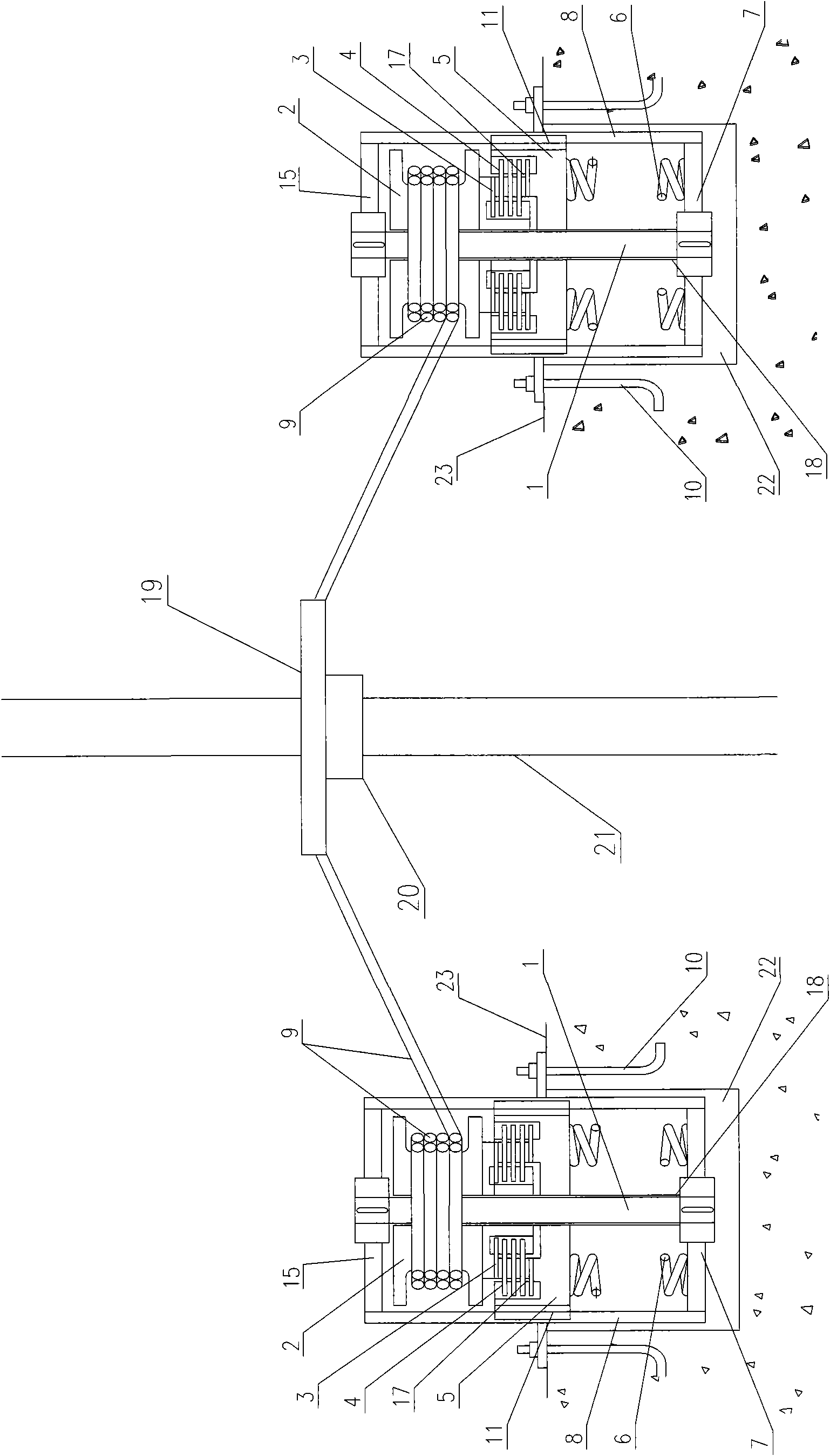

Embodiment 1

[0020] Embodiment 1. A variable resistance energy consumption energy absorber, including a central screw 1, a driving wheel 2, an upper supporting seat 15, and a lower supporting seat 7, wherein: the driving wheel 2 is provided with a central hole 12, and the central hole 12 is An inner nut 13 is fixedly connected with the central screw 1; one end of the driving wheel 2 is provided with an outer groove 14, and the outer groove 14 is engaged with the active friction plate 3; the other end of the driving wheel 2 is provided with a roller 16, which can be wound And fixed steel wire rope 9; Upper support seat 15 and lower support seat 7 are fixedly connected by central screw rod 1; The inner surface of lower support seat 7 is connected with several rotary springs 6, and the other end of rotary spring 6 is connected with passive bearing plate 5; Passive friction plates 4 are arranged on the passive drive plate 5; the passive friction plates 4 and the active friction plates 3 are alt...

Embodiment 2

[0021] Embodiment 2, a variable-resistance energy-consumption energy absorber, wherein: an anti-rotation sliding strip 8 is also provided, one end of the anti-rotation sliding strip 8 is fixedly connected to the upper support seat 15, and the other end is fixed to the lower support seat 7 Connection; the outer edge wall of the passive bearing plate 5 is also provided with several chute 11, and the chute 11 can be connected with the anti-rotation slide bar 8. All the other are with embodiment 1.

Embodiment 3

[0022] Embodiment 3, a variable resistance energy consumption energy absorber, wherein: the passive bearing plate 5 is provided with an inner groove 17 which can be fixedly connected with the passive friction plate 4 . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com