Laser engraved linear array light guide plate and preparation method thereof

A laser engraving and light guide plate technology, applied in light guide, engraving, optics and other directions, can solve the problems of low brightness, poor light refraction effect, and inability to produce light guide plates, etc., to achieve uniform reflection and better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

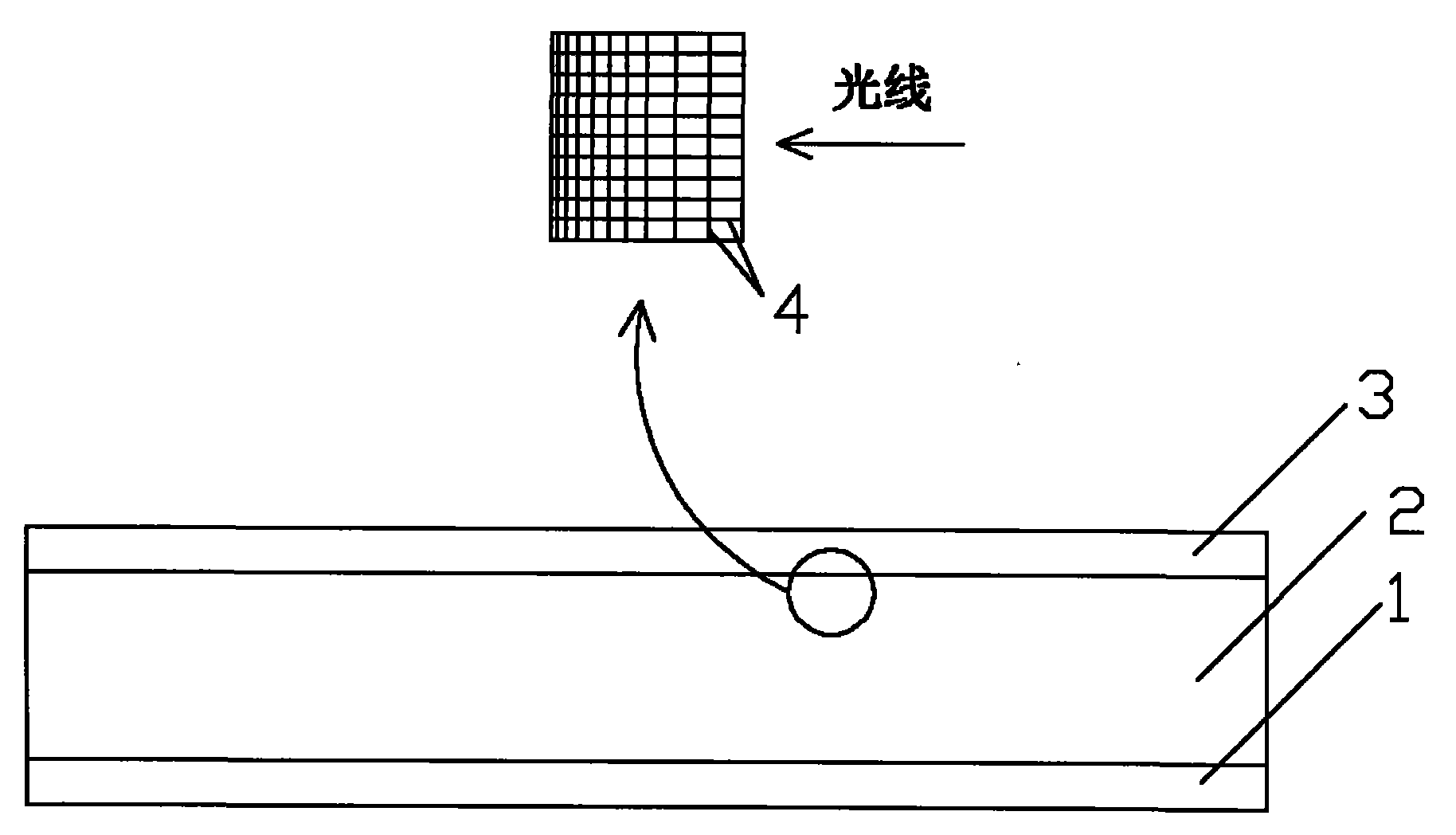

[0027] The present invention is specifically described below in conjunction with accompanying drawing

[0028] see figure 1 , a laser-engraved linear array light guide plate according to the present invention, the light guide plate made of acrylic flat plate includes a reflective layer 1 made of a material with high reflectivity and a material with high light transmittance The prepared light guide layer 2 and the diffusion layer 3 made of homogeneous materials; it is characterized in that, the light guide layer 2 of the light guide plate is distributed with several reflective diffusion lines engraved with laser pulses horizontally and vertically. A linear array composed of 4; among them, the diffusion lines between the linear arrays of vertical light rays are parallel to each other and arranged in an arithmetic sequence, and at the same time, according to actual needs, the closer the light guide plate is to the light source, the sparser the line array is, and the farther away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com