Active P-V characteristic correction method and device for photovoltaic component

A technology of photovoltaic modules and calibration devices, which is applied in the fields of electrical components, semiconductor devices, climate sustainability, etc., can solve the problem of complex maximum power point tracking algorithm parameter design and implementation, and cannot guarantee the global maximum power point of photovoltaic modules. Output power reduction and other issues, to achieve the effect of improving energy conversion efficiency, low cost, and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

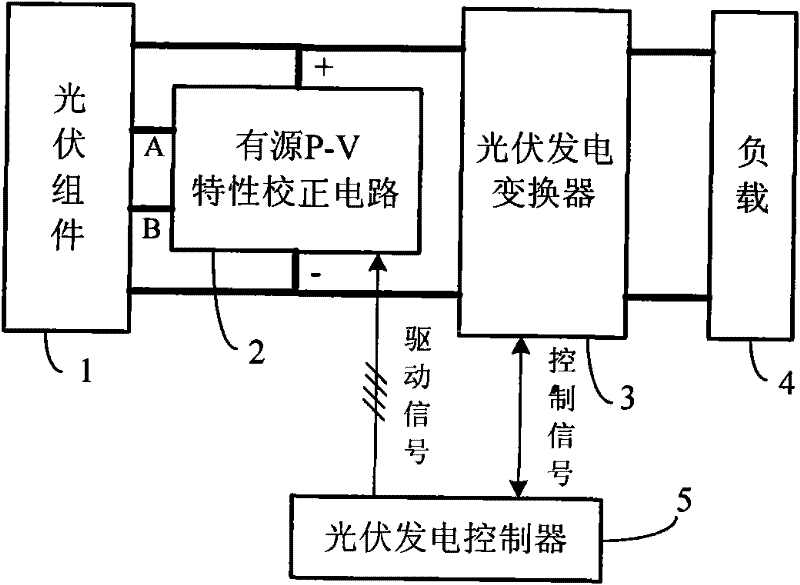

[0018] image 3 It is a block diagram of the maximum power point tracking system applying the active P-V characteristic correction circuit of the present invention, including a photovoltaic module 1, an active P-V characteristic correction circuit 2, a photovoltaic power generation converter 3, a load 4 and a photovoltaic power generation controller 5.

[0019] The internal wiring diagram of photovoltaic module 1 is as follows: Figure 4 As shown, the photovoltaic module 1 is a commercial photovoltaic module with the following characteristics: it is composed of a large number of photovoltaic cells connected in series, divided into three groups on average, and connected with three bypass diodes in parallel. The positive pole of the photovoltaic module, the cathode of a bypass diode in the middle, the anode of a bypass diode in the middle and the negative pole of the photovoltaic module are the "+" terminal, "A" terminal, "B" terminal and "-" terminal of photovoltaic module 1 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com